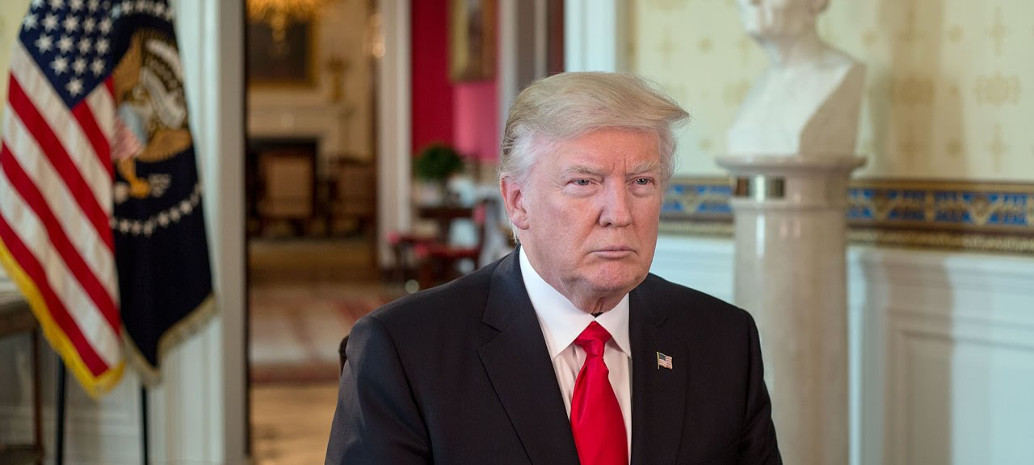

In statements made at the National Governor’s Association Winter Meeting, President Trump has claimed that the administration’s 30% tariff on imported solar cells and modules is generating manufacturing benefits for the United States. The President also touted U.S. solar panel quality relative to Chinese manufacturing.

Per a report from TheHill.com, Trump took time at the meeting to mention the Section 201 trade tariff, one of the few times he has discussed the solar industry since becoming president. He began by claiming the U.S. had, at one point, 32 solar panel manufacturing plants, but that 30 of them had closed down.

“Now, they’re talking about opening up many of them, reopening plants that have been closed for a long time,” Trump said. “And we make better solar panels than China. One of their knocks were that the solar panels were lousy, they weren’t good. We make a much higher quality solar panel.”

In evaluating Trump’s statement, quality is inherently hard to measure. While it is notable that no Tier 1 Chinese companies offer 25-year workmanship warranties, PV modules made in Southeast Asia and Japan offer such assurances, as do those produced by Oregon’s SolarWorld. SunPower’s X-Series modules – made in Southeast Asia – offer higher efficiencies than any U.S.-made products.

Also, the track record of the Section 201 tariffs so far are mixed. By pv magazine’s count, 880 new solar manufacturing jobs have been announced, and 200-300 more can be assumed, with a possibility of another 200 more. No closed manufacturing facilities have re-opened; however, one company – MissionSolar – has announced they will increase production on existing lines.

JinkoSolar also announced a deal to invest US$410 million and build a PV module manufacturing factory in Jacksonville, Florida. The company estimates 800 new jobs will be created.

Solartech Universal, also in Florida, announced an expansion of its Riviera Beach based work force from 45 to 75 by adding a new production shift. The company has approximately 80-85 MW of annual manufacturing capacity in the U.S.

Solaria, a California manufacturer, announced an expansion of its global manufacturing capacity from 100 MW/year to 300 MW/year by the end of 2018, including an expansion of its U.S. production. Currently, the group has a capacity of 40 MW/year at its Fremont, California facilities. It has not provided details as to how much capacity it will add in the U.S., or the numbers of U.S. jobs it will create.

Mission Solar, based in Texas is also expanding. It has already rehired 50 workers to bring it back to a 200 MW/year capacity. And just three weeks ago, pv magazine discovered that the company plans to double the capacity of its production in San Antonio, from 200MW/year to 400 MW/year. The number of jobs involved is not known.

Furthermore, SolarWorld announced in September, at the outset of the Section 201 trade case, that they might re-hire 200 workers by May of this year as a result of greater market confidence. As of December, they had not made any new hires, however.

It is notable that Trump’s statement did not accurately present the current number of U.S. PV module factories. pv magazine has found 17 full-scale PV module manufacturers in the United States, plus a 5 MW/year pilot line owned by SunPower.

And to put these jobs in perspective, Solar Energy Industries Association (SEIA) warns of 23,000 fewer solar jobs as a result of the tariff, due to lower installation volumes caused by higher prices.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

Readers may recall one of the casualties of the early (2012) panel price declines was the San Francisco Bay Area firm Solyndra; the firm declared bankruptcy despite a $500 million DOE loan guaranteed as part of President Obama’s effort to save and create jobs through ARRA. Solyndra became the poster child for ARRA’s critics, ignoring the impact of the below-cost competing panels.

In light of the effort to protect domestic manufacturers with the new tariff, I assume those who were critical of the earlier effort to save jobs may add a tag line to the President’s current effort:

Trump’s Solar Tariff: bringing back Solyndra!

🙂

23 000 jobs lost vs.808 jobs gained

I guess Americans already tired of winning