In our webinar on October 30 2018, we asked experts what the advantages of half-cut cell modules are and what installers need to be aware of during installation.

They discussed how cell to module losses are reduced within half cut modules and can even turn into a gain. Additionally, the new modules perform better in certain shading situations, for instance, if the lower part of an installation in portrait orientation lies in shadow.

Now, Max Mittag, head of team module efficiency, PV Module Technology Department, Fraunhofer ISE and Klaus Hofmeister, product manager, Trina Solar, answer the questions that could not be addressed in the webinar.

Click here to download presentations or watch a recording of the webinar.

pv magazine: 75% power loss reduction neglects the increase in the contact resistances, due to double the number of contacts. How much do the contacts typically contribute to the resistance? You said that the half-cut cell module has the same number of soldering points. How is that possible if the number of cells doubles?

Max Mittag: The number of (solder) contacts does not increase. They are just distributed to the two half cells. The contact resistance between cell and interconnector ribbon is usually very low for solder interconnection.

Can bifacial half cut cell modules also be expected to have higher output from the back side based on the same principles?

Bifacial half cell modules will profit from the reduced currents, due to the quadratic relation between losses and current (P_loss = I² x R).

Is it true that low irradiance performance is worse than full cell module?

The half cell module will have an advantage compared to the full cell module at any irradiance. But the advantage will be lower at lower irradiances. STC-measurements “overestimate” losses for full cell modules.

If the cell-to-cell distance is decreased even down to 1mm, will the power of the module decrease?

The power of the module will decrease due to a reduction of backsheet reflection.

Are flash-tests still reliable with the lower currents per cell?

Due to a different module topology (changes in internal connection of strings), the output parameters of half-cell modules will be the same as for full-cell modules. IV-test equipment will be able to measure half-cell modules.

There is cell efficiency loss when a cell is cut. Do you account for this? Is cell separation responsible for cell power loss (slight degradation of cell)?

Yes, depending on your exact cell, power losses from splitting can occur. Our cell-to-module loss analysis models can account for losses due to cell splitting.

What is round wire interconnection?

Replacing the rectangular interconnector ribbons with round wires is possible and offers several advantages. See for example “SmartWire” by Meyer Burger or “Multi-Busbar” by Schmid.

Do half cut cell modules have better resistance to microfractures? And will there be a warranty from the manufacturer?

Klaus Hofmeister: Due to the smaller cell size, at least in one direction of the module, it could be expected that the cells are performing differently with respect to micro cracks. However Trina hasn’t seen any data to confirm it. Surely the half-cut cell modules perform equally well or even better than full cells. The manufacturer’s warranty is the same as for full cell modules; there is no difference because of the half-cut cell design.

Are there any complications installing the halfcells horizontally, and are the cables long enough?

Half-cut cell modules can also be installed horizontally without any complications. The cables are long enough for most installation situations.

Do you believe the halfcut is just an interim solution before bifacial is more cost efficient?

The effect achieved with half-cut cell modules – reducing the internal current in the module – also applies with bifacial modules. So it will definitely be used for bifacial modules as well, in parallel to monofacial modules.

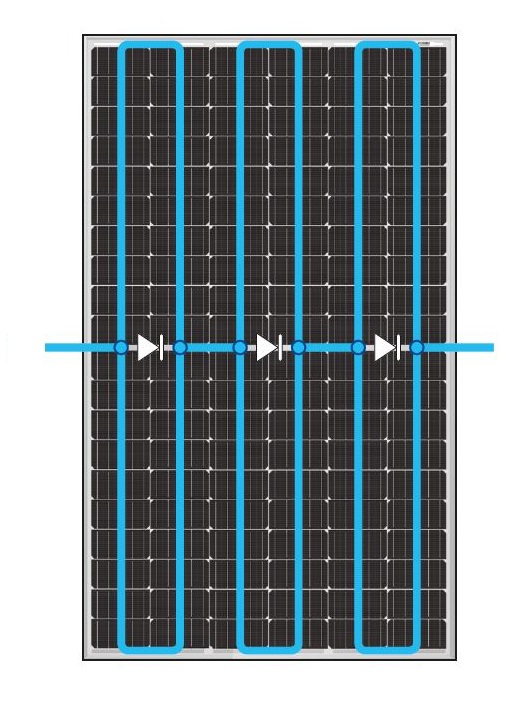

How are the bypass diodes connected into the modules, what is the difference to full cell modules?

pv magazine / Harald Schütt

The bypass diodes are connected in parallel to the upper and lower half of the module, and each of them is connected to 20 half cells in either half of the module (as illustrated in the picture). The major difference appears when shading moves in from the short side of the module, covering up to 50% of the module surface. That allows the other unshaded half of the module, which is fully exposed to the currently available irradiation, to work in the optimal MPP.

How do halfcut cells, together with n-type or p-type cells, increase efficiency?

The efficiency increase at the module level, due to half-cut cells is independent of the cell technology. The physical principle, stating that reduced currents in the module reduce the resistive losses, is valid at any time.

How much bigger is the module in square meters compared to a standard one?

Basically the change only increases the length of the module by approximately 20mm and should not affect the width.

How well do you think the half cut modules will age? Should we be aware of future mismatches between the parallel subsections of each module over the long term?

There is no indication that half-cut cell modules will show a different aging behavior compared to full cell modules. That is also underlined by the fact that manufacturer’s warranties weren’t changed after switching to half cut. Cell-to-cell mismatches are relatively low compared to other degradation effects within the modules, such as the aging of materials used. Mismatch losses within a module string are considered to have a higher impact.

Is the cell temperature the same as with full cells? Are half cut cell less sensitive to ambient temperature?

Module efficiency increase goes along with the fact that the irradiation absorbed is more efficiently converted into electricity rather than heat. This results in a slightly lower temperature. Half-cut cell modules are equally sensitive to ambient temperature because the temperature coefficients are still the same.

Is the next stage to divide cells again into quater cells? What is the limit?

Theoretically a further reduction of cell size is possible. However a prerequisite for the half-cut cell module was to maintain electrical parameters in terms of open circuit voltage and MPP voltage, so that half-cut cell and full cell modules can be exchanged without a complete re-design of the system. With further reduction of the cell size, it would become much more complex to keep the electrical parameters, and to develop a reasonable and manufacturable module.

How are operational PV plants equipped with half cut cells performing?

At the moment, no long-term operational data of half-cut cell modules is available. We can only predict that the performance on the long run is similar to full cell or even slightly better.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

Hi Comelia

thanks for bring the half-cut module to the platform. but from our study , we found the half-cut module has a fetal issue that makes the diodes very harder to be triggered to elimate the hot-spot leading the hot-spot heating up the cell all time. we also found that hlaf -cut module mfgs mis-lead the public on its 50% unshaded area still working when covering 50% another side of the module, unfortunately it was not true in a real system.

(1) the conclusion from Trina on : The major difference appears when shading moves in from the short side of the module, covering up to 50% of the module surface. That allows the other unshaded half of the module, which is fully exposed to the currently available irradiation, to work in the optimal MPP. ” is totally wrong. Their result was tested with single module with pasan at the Lab. The real result in a working system is that the shaded helf cut module output will be 100% by passed. , Surprised that being a tier 0ne compnay, their RD team didn’t put their new product in a real system to test and verify. everyone could re-verify the performance of this 50% unshaded half module in a real system.

(2) the second fetal of the hlaf-cut module is the its difficulty of turning on its by-pass diodes in a test environent, you have to cover its up to 90% of a half-cut cell area, or say 90%*156*78 to trigger the by-pass diode to turn on. otherwise, the by-pass diode would not work to by-pass the mis-match current to solve the hot-spot. the hot spot would heat up the cell until its diode be triggered, unfortunately it was almost impossible.

if possible, pls forward my comments to both Trina and Fraunhofer ISE. thanks

if you want a module without by-pass function to elimate the hot spot, yes, half cut module mauy your option.

Hello, i think greed and laziness is the problem here, wanting to use the connection box already at hand, you should use six diods not three, three for each half panel, the whole panel should be regarded equivalent to two solar panels connected in parallel. Only three diods cannot work as protection as two cell strings are connected in parallel three times. Should only one cell in one of the two paralleled cell strings be shaded you can have a problem. In my opinion this should be obvious to any electric engineer. Just an opinion.

Hello!

Does it mean the output voltage will twice as intact cells of a module?

PS: I am not an electric engineer

Hi Unvar, hopefully this webinar will help answer your question: pv-magazine.com/webinars/are-half-cut-cell-modules-the-future/