“Anyway, like I was sayin’, shrimp is the fruit of the sea. You can barbecue it, boil it, broil it, bake it, sauté it…” And the list went on. Some 25 years later the Fraunhofer Institute for Solar Energy Systems has identified another use to add to the list Bubba told Forrest Gump: You can also use it with PV panels.

Fraunhofer ISE is working with the German government’s international development body GIZ and domestic seafood supplier Viet Uc Seafood on a project saddled with the somewhat forced-acronym driven title Solar aquaculture Habitats as Resource-efficient and Integrated Multilayer Production Systems – SHRIMPS.

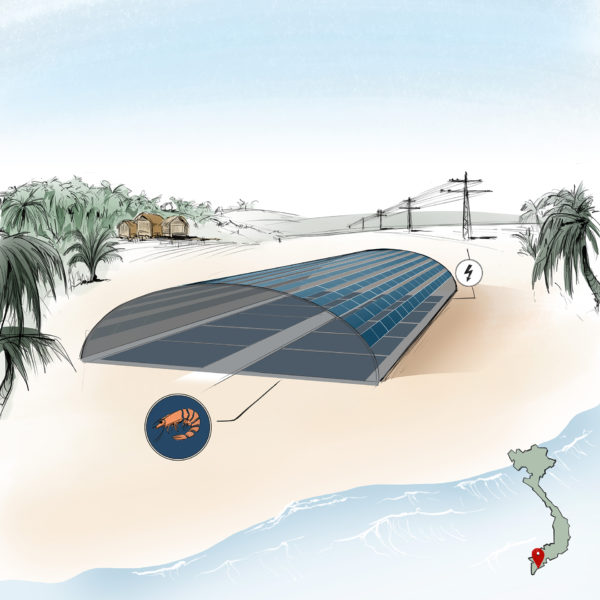

The research institute had already worked with GIZ in Vietnam last year on combining PV power generation with shrimp farming. Now the project partners want to take the approach to the next level and test the technical and commercial feasibility of dual land use for solar power generation and commercial aquaculture.

The land-based acquaculture farms common in Vietnam usually cover their water tanks with a canopy to protect against diseases carried by birds which attempt a spot of fishing or whose droppings could otherwise land in the water. With land scarce in the densely-populated nation, using the canopy space for solar panels could kill two birds with one stone, so to speak.

And it is not just carbon savings from clean energy generation that are on offer. Life is like a box of chocolates, as Forrest might say: you never know what you’re gonna get.

Adding modules to the roof structure means more shading can be provided and temperatures below the canopy fall slightly, prompting increased growth rates among the shrimp.

Improved shading also means lower water use. The Mekong basin and delta are the primary drinking water sources for Vietnam and also host plentiful aquaculture facilities. Reducing their water consumption could bring huge advantages to the population.

Fraunhofer ISE says, according to its initial analyses, a 1 MW project installed in Bac Lieu should see a CO2 reduction of around 15,000 metric tons per year and water consumption would fall by 75% per year compared to a conventional shrimp farm.

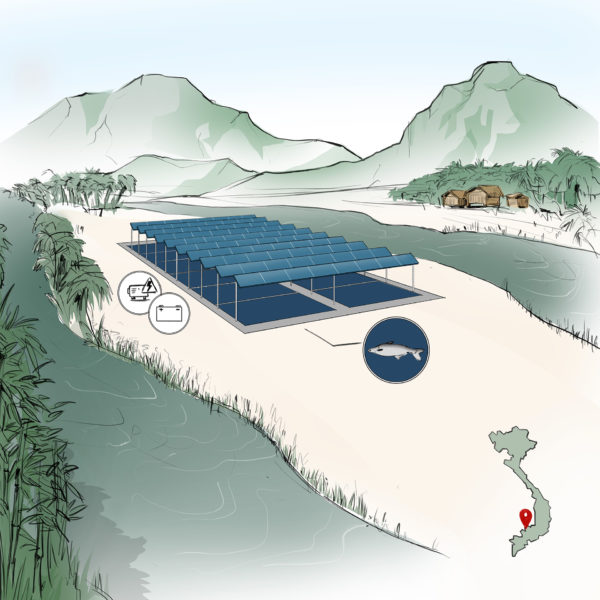

The project partners are working to install another 400 kW solar roof structure over a farm for pangasius – shark catfishes. The plant will reportedly meet all the power demand of the fish farm and will be designed as a hybrid system for use as a fully off-grid application.

“We want to use this project to demonstrate the added value that can be generated by integrating photovoltaics into different areas of life,” said project manager Maximilian Trommsdorff, of Fraunhofer ISE. “For aqua-PV we’re currently working on the assumption that the land use rate can be almost doubled compared with a ground-mounted PV system alone.”

A planned pangasius farm PV plant, including self-sufficient energy supply, in An Giang.

Initially the project will run for three years, with simulations examining performance and effect on smaller sites before two larger installations are built, said Fraunhofer ISE.

“In the third step, we’ll then scale down again to develop a solution for small and medium-sized aquaculture businesses,” added Trommsdorff. “This will make the approach accessible for the average rural inhabitant in terms of the technology and investment needed.”

The German Federal Ministry of Education and Research is also backing the project with a research and sustainable development grant. SMA Sunbelt Energy GmbH, Suntrace GmbH and the Thünen Institute of Fisheries Ecology are also on board.

On the Vietnamese side, Nong Lam University, the Vietnamese Institute of Energy and the Viet Uc Seafood Corporation are also partners.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

4 comments

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.