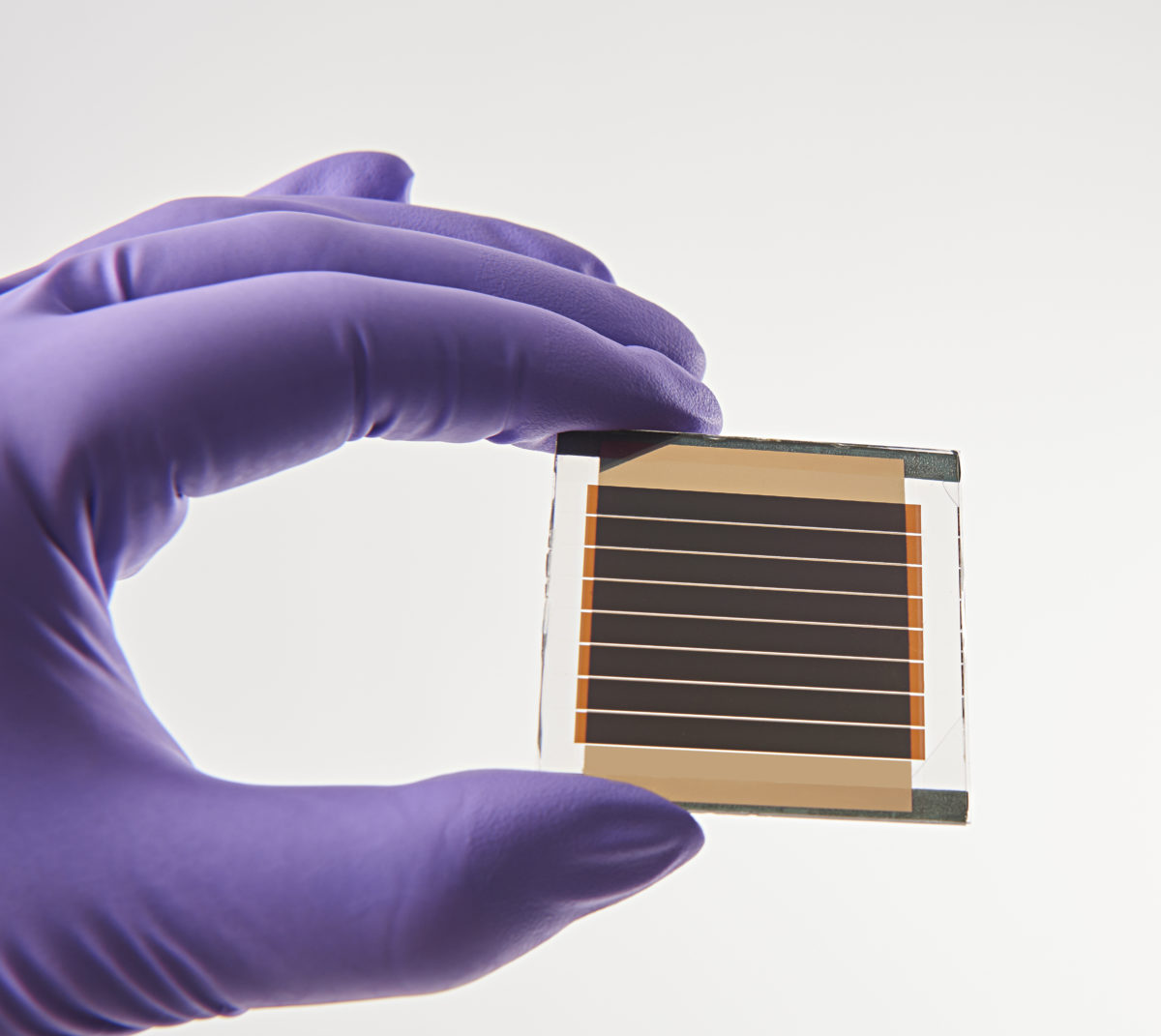

The new-energy technologies and nanomaterials (Liten) branch of the French Alternative Energies and Atomic Energy Commission (CEA) has developed a 20.3% efficient mini PV module featuring eight perovskite cells.

The device, which has an active surface of 11.2 cm², was produced in a three-step process which included layer deposition with a laser structuring technique based on an ultrafast, picosecond laser.

The module’s cells, which have a reported fill factor of 93%, were made with a gold electrode on top; a polytriarylamine hole transporting layer between electrode and perovskite film; a tin(IV) oxide (SnO2) electron transporting layer under the perovskite; and a transparent indium-tin oxide (ITO) conductive layer at the lowest level. The perovskite used was defined by the researchers as a CsyFA1-yPb(I1-xBrx)3 multi-cation system.

“What is important to notice is that the architecture was kept simple, with no additional step or additional layer either for the electron transporting layer or the hole transporting layer,” said Solenn Berson, head of the CEA’s laboratory of organic and perovskite PV modules. She told pv magazine the CEA has been working on the technology since 2015.

Previous records

Popular content

The Liten research group achieved 15.9% efficiency with a similar device in 2018 and 16.9% early last year.

The cell was improved by optimizing composition of the n-type interfacial layer and improving the thickness homogeneity of the perovskite layer through a coating technique. The coating led to improvement of crystallization of the perovskite layer and of charge extraction between the electron transporting layer and the perovskite material, according to Berson. The hole transport layer material was also optimized, to improve the hole extraction from the device.

The module was said to have a stabilized efficiency of more than 19% at maximum power point testing. The Liten developers claim the device can retain around 90% of its initial performance after 1,000 hours of continuous illumination.

“The perovskite technology is now on its way to be industrialized, maintaining high efficiency on [a] larger area device by developing slot-die coating techniques,” Berson added. The slot die process is similar to roll-to-roll coating and is used for depositing highly uniform films.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.