From pv magazine Germany

The efficiency of thin-film solar cells based on copper, indium, gallium and selenium (CIGS) semiconductors has improved to more than 23% in recent years, thanks to ongoing research.

However, a team of researchers from the Center for Solar Energy and Hydrogen Research Baden-Württemberg (ZSW), Martin Luther University Halle-Wittenberg (MLU), and Helmholtz-Zentrum Berlin (HZB) see the potential for further efficiency gains. They have outlined their findings in a recently published article in Nature Communications.

Their findings are based on research in the joint EFFCIS project, which ended this year. The 3.5-year initiative was funded by Germany's Ministry for Economic Affairs and Energy.

The researchers claimed that a theoretical efficiency of around 33% is possible for CIGS thin-film solar cells. The discrepancy arises from loss mechanisms in the CIGS solar cell, which can occur in the functional layers, but also at several of the cell interfaces. So far, this has only been suspected and there has been much discussion about where and why these losses occur. The German research team claims it has been able to localize them.

“Some of the losses occur at the boundaries between the individual CIGS crystals of the solar cell,” said project manager Wolfram Witte from ZSW. “At these so-called grain boundaries, a certain proportion of which is also electrically active, positive and negative electrical charges can neutralize each other.”

To identify the loss mechanism, the researchers combined an experimental measurement method with computer simulations. For this purpose, HZB analyzed a highly efficient CIGS solar cell using various electron microscopy processes and optoelectronic measurement methods. Their aim was to provide the team with the most realistic values possible for their two-dimensional component simulation.

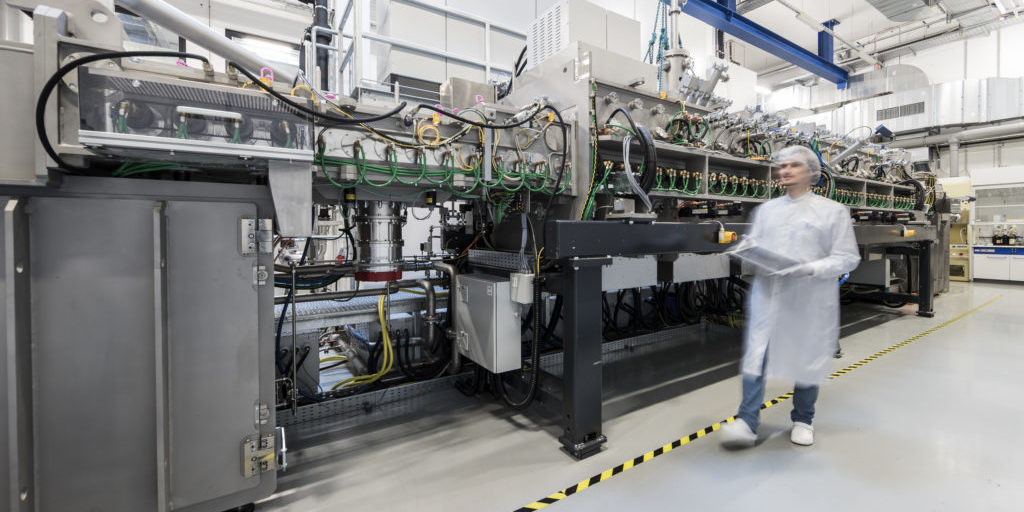

The ZSW produced the CIGS solar cell using the co-evaporation process, in which the elements copper, indium, gallium and selenium are deposited at the same time in a vacuum. Without an additional anti-reflective layer, the cell achieved an efficiency of 21%. The real microstructure of the cell was used with the experimentally obtained values of the various analysis methods as input parameters for the two-dimensional simulation, the researchers said.

The analysis showed that increased recombination at electrically active grain boundaries within the CIGS layer contributes to significant losses. This worsens the open-circuit voltage and the fill factor, thus reducing the efficiency of the solar cell.

“In order to further improve the efficiency of CIGS thin-film solar cells and modules in the future, the density of the electrically active grain boundaries should be reduced and CIGS layers with larger grains should be produced,” explained Witte.

This is technically possible through additional additives in the CIGS layer, the adaptation of the substrate material, or via an optimized temperature balance during coating.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

Vietnam is a rapidly developing country. Why don’t you see any news about them?