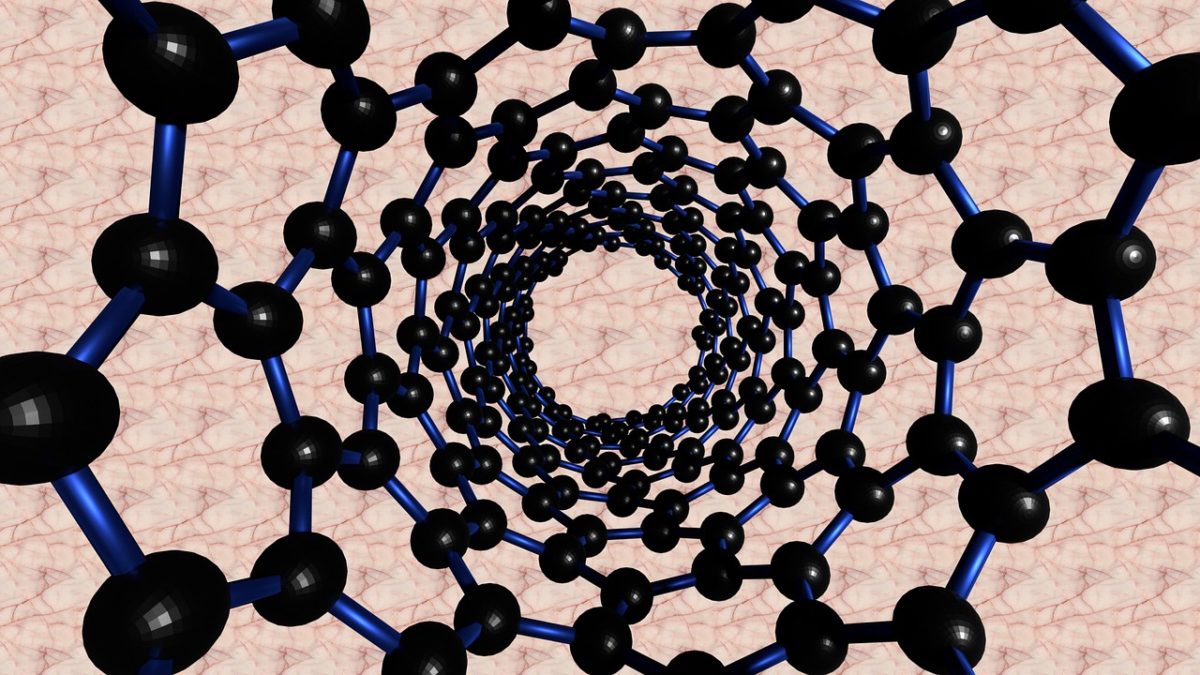

Researchers at Germany's Karlsruhe Institute of Technology have proposed a roadmap for carbon nanotubes (CNTs) used in photovoltaics that analyzes all possible applications of these cylindrical molecules in different kinds of solar cells. “In principle, all elements of a solar cell, from the light sensitive component to carrier selective contacts, layers for passivation and transparent conducting films can be replaced by carbon nanotubes and their composites,” they stated in the paper Carbon Nanotubes for Photovoltaics: From Lab to Industry, published in Advanced Energy Materials.

The scientists predicted a brilliant future for CNTs for PV devices, explaining that the barriers to their application are constantly being reduced at the research level. They pointed out three main fields of research that may help bring this technology closer to industrial production: the separation, purification, and enrichment of CNTs; their integration into organic solar cells as a photosensitive element; and their integration in silicon solar cells as hole selective contacts. “All three subtopics have experienced tremendous growth over the past 20 years and certainly the performance of the silicon‐based cells is now rapidly approaching that of those on industrial production lines,” the German team explained.

As for the first of the three fields, the researchers specified that in recent researches highly selective separation techniques in aqueous and organic solvents have been developed and that the most applied technique is an organic‐based polymer extraction method. They also explained, however, that this process cannot be arbitrarily applied to all raw soot and is limited to two kinds of chiral nanotubes. “Using pricing from common chemical suppliers it is possible to make an estimate of the cost/gram of (6,5) from polymer extraction and it immediately becomes clear why this method continues to remain unattractive for industry,” the German group added. “Obviously, this is only an estimate and it is possible to make arguments about cost reductions associated with economies of scale and thus the real production cost being much lower, or indeed that other research groups have a better yield than us (0.025–0.05%), but it is unlikely that these will reduce the price of (6,5) to a level that is comparable to traditional organic photovoltaic materials.” If these price and yield issues will be addressed and resolved, however, a path towards mass production may not be completely excluded.

In the organic PV research, the academics went on to say, single-walled (SWCNT) carbon nanotubes are being used for exciton dissociation in the photoactive layer or as electron acceptors. “SWCNT‐based solar cells have almost exclusively been fabricated in bilayer stacks between an indium tin oxide (ITO) substrate and metals like silver or aluminum,” they stressed. High performances in these devices, however, can only be achieved with SWCNTs with high semiconducting purity. Further improvements in the light absorption of these solar cells and the correspondingly low efficiency are needed to bring them closer to the performance of thin-film solar cells.

In silicon photovoltaics, carbon nanotubes are used as hole selective contacts and have also been utilized in a CNT:Nafion ink that can reduce the complexity of fabrication of n‐type solar cells. “For CNT:Si solar cells, chiral selection is typically limited to raw soot and/or chiral species with optical transitions located outside the spectral range of silicon (350 –1100 nm), thus maximizing light absorption by silicon, and/or to large diameter species due to their increased conductivity,” the researchers highlighted. So far, solar cell architectures similar to those of organic cells were utilized, with a window or frame like geometry defined in the middle of a silicon wafer. “This design was successful for many years because it allowed for the CNT film to be processed separately and later transferred to the window,” they added. This geometry, however, is limited and it is unlikely that it will be brought to industrial production lines. Recently, a promising passivation scheme involving organic thin films has also been developed.

“In order for the industrial uptake of carbon nanotubes to occur they must find their niche because they are faced with strong competition from alternative materials and/or photovoltaic designs,” the authors of the research highlighted, adding that the most promising applications of carbon nanotubes may be in organic‐CNT solar cells on the rear of these cells or in a tandem architecture with CNT:Si cells. “These would certainly take advantage of the unique infrared peaks of the CNTs and lead to highly efficient devices,” they concluded. “However, current matching between the two cells will be difficult and will require a twofold increase from the organic‐CNT cell and thus significantly thicker CNT films.”

In recent years, several kinds of research were conducted on PV carbon nanotubes. In April, Russian researchers improved the efficiency of a thin-fim GaAs‐based solar cell by 0.9% by applying single‐walled carbon nanotubes as the topmost layer. In October 2019, scientists at the Tokyo Institute of Technology developed a carbon nanotube which forms a strong junction with a lead-halide perovskite, improving performance and stability.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

2 comments

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.