Netherlands-based Rads Global Business BV has developed a multifunctional anti-soiling nanocoating for solar glass that is also claimed to mitigate potential-induced degradation (PID), and to be anti-reflective and anti-corrosive.

“This coating can be used for dry cleaning by robots in large PV plants,” company CEO, Rajbeer Singh, told pv magazine. “It increases the efficiency of wet cleaning by reducing water consumption in the range of 50 to 70% due to the self-cleaning function of the coating,” he said, noting that soiling, scaling, corrosion, abrasion and glass reflection can reduce transmission of light through the module glass in real field conditions in a range of 5% to 20%.

According to him, the coating solution can increase the performance of a PV power project by between 5 and 15% and ensure a reduced cost of cleaning and fewer damages to PV modules due to corrosion and operation and maintenance. “Our coating can reduce the cost of cleaning by 60%,” he explained, adding that revenue increase for a PV project in deserts and the polluted site could be in the range of 8 to 18%.

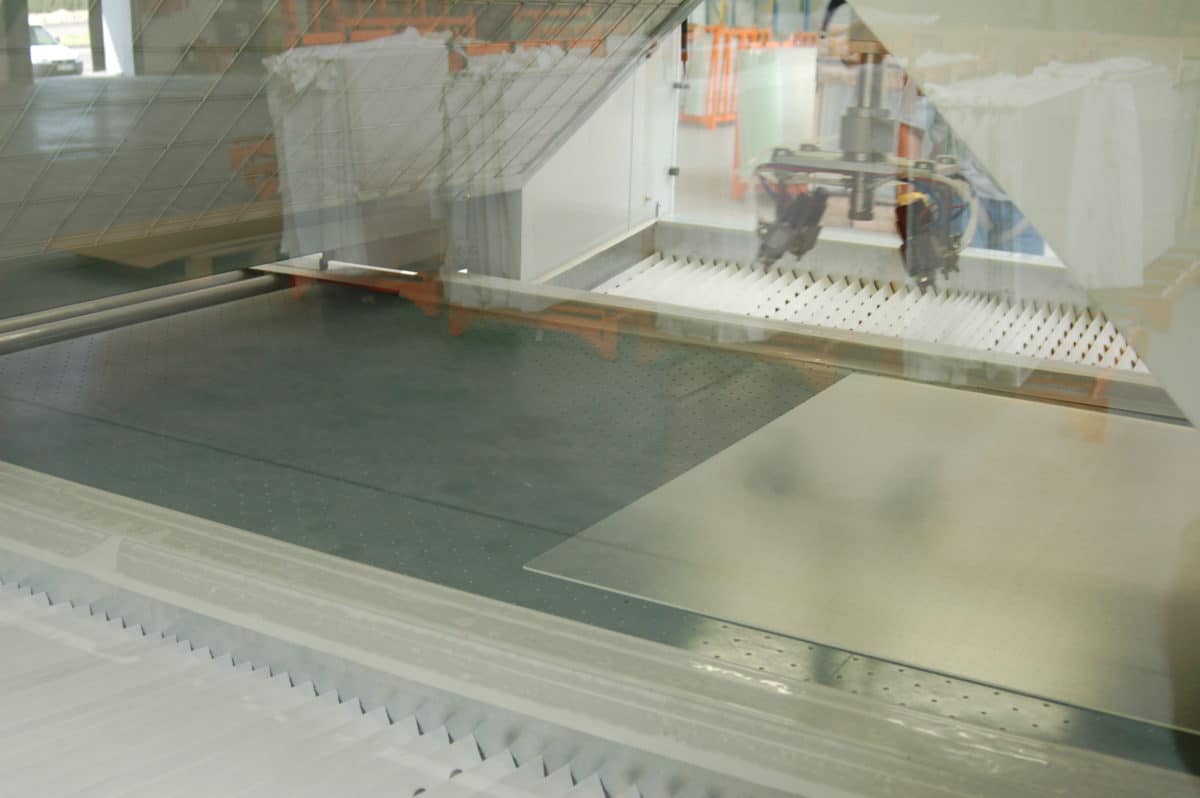

The technology is patented in the Netherlands and the coating production is planned to be located in India, wh ere a factory is currently under construction. “As the coating is applied to the tempered cut size solar glass, the coating line can be installed with any solar glass manufacturer as well as PV module manufacturer,” Singh said. “The coating is applied through a chemical combustion vapor deposition (CCVD) process and this process makes it highly durable.” According to him, the coating could be applied directly to the module in a panel factory or onto the solar glass in a glass factory.

ere a factory is currently under construction. “As the coating is applied to the tempered cut size solar glass, the coating line can be installed with any solar glass manufacturer as well as PV module manufacturer,” Singh said. “The coating is applied through a chemical combustion vapor deposition (CCVD) process and this process makes it highly durable.” According to him, the coating could be applied directly to the module in a panel factory or onto the solar glass in a glass factory.

Popular content

The coating has already shown extremely good results in real field conditions, according to Singh. It was applied manually to a solar park in Delhi, India, and tested during 2016 and 2021. The test showed that it helped the modules produce approximately 8.9% more power than non-coated modules located at the site.

“This product can be applied to the existing PV fields, which means the existing projects can get extra revenue and reduced cost of operations and maintenance,” the CEO continues. “Since water for cleaning is a serious challenge for all the existing big PV projects in water scarce regions, this coating can be a rescue for these projects”

According to him, the cost of the coating through the coating line may represent between 2 and 3% of the total cost of a PV project.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

Nice article !

Just a misprint at the end, I believe it’s “water scarce regions” instead of “water scares regions”

Hi Nono, thanks for your message. The text was amended.