Scientists at the University of Washington have developed an active self-cleaning surface system for PV modules based on mechanical vibration and anisotropic ratchet conveyors (ARC), which are hydrophilic curved rungs on a hydrophobic background.

The researchers said that the system could rely on different material combinations with hydrophobic and hydrophilic behaviors and that they utilized two kinds of coatings: a sperfluoro-octyltrichlorosilane (FOTS)-trimethylsilanol (TMS) self-assembled monolayer (SAM); and a Cytop-TMS spin-coated thin-film. “Cytop is an amorphous fluoropolymer with good transparency over the visible and UV wavelength ranges, good solubility to coat various surface designs, and excellent water repellent properties,” they explained.

After the FOTS-TMS treatment, the glass of the module is still transparent and optically flat, while the Cytop-TMS film improved the transmission with an enhancement of between 2.5 and 3.5% over the visible wavelength range. “The Cytop-TMS coating generated higher optical output power than bare glass and FOTS-TMS surface treatment, in accordance with the light transmission measurements,” the academics said. “The optical performance demonstrated that our coating systems were compatible with solar module cover glass and can even have anti-reflective properties to improve solar module power output efficiency.”

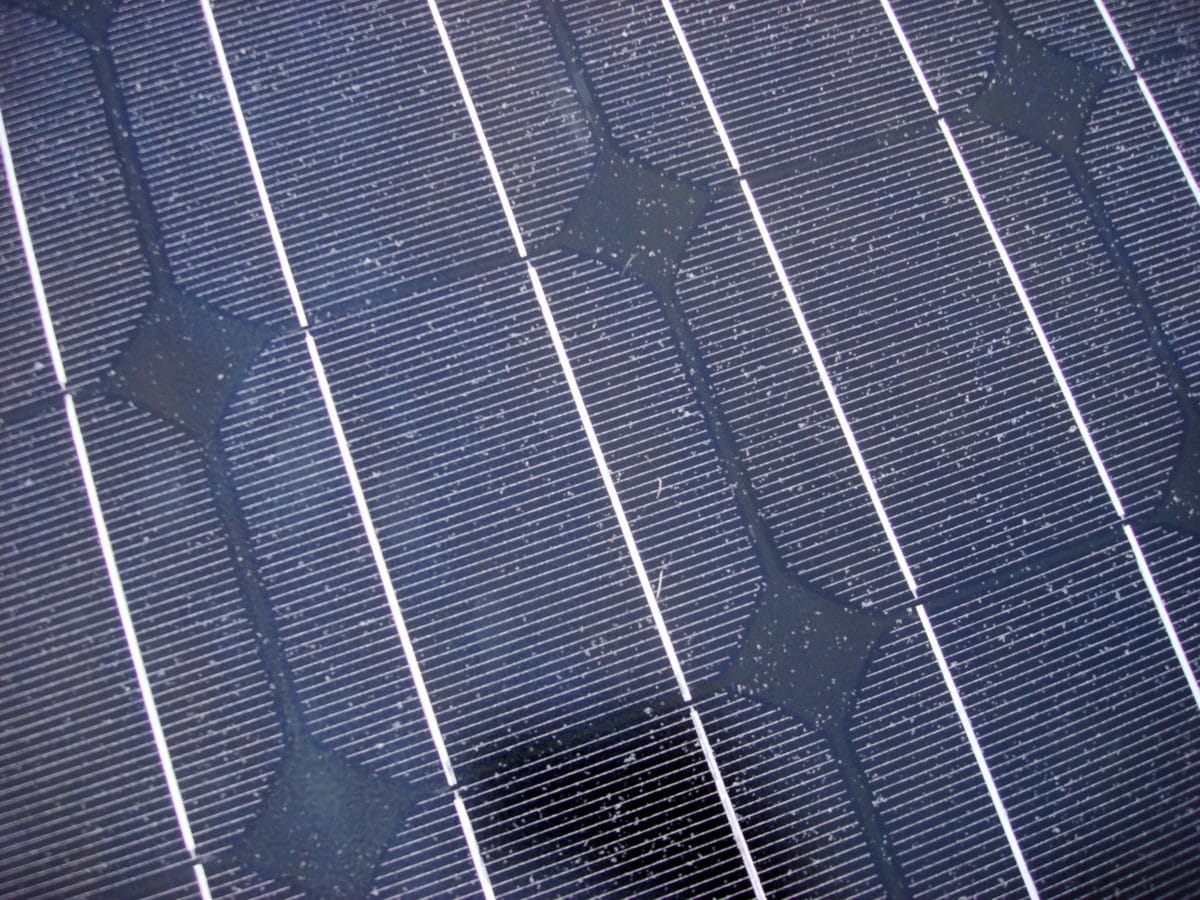

The tested PV device was equipped with the ARC patterns and placed on a vibration stage. Water droplets were applied with a pipette to the surface and transported, under vibration, to the contaminated parts to remove dust particles. The droplets were able to overcome the force of gravity and climb on the device's inclined surface under orthogonal vibration. “Our experiment showed that the droplet can climb uphill at up to a 15-degree inclination of the surface,” the scientists highlighted. “With higher inclination angles, the droplet tended to be shaken off the surface.”

According to their measurements, the tension force of the module surface and the water hydrodynamic shear force are able to remove the surface contaminants as the droplet moves onto the surface contaminants, which include water-soluble, insoluble, hydrophobic, and hydrophilic dust particles. “Dust particles were dislodged by the surface tension force and the hydrodynamic force, while encapsulated by the internal flow of the vibrating droplet,” the group explained.

The researchers claim that the system makes limited use of water as it uses 10 μL droplets. “The entire fabrication consists of a single-mask process to reduce manufacturing costs,” they concluded, without adding specific figures on the costs that the technique will add to those of a PV system.

The proposed approach is presented in the paper An active self-cleaning surface system for photovoltaic modules using anisotropic ratchet conveyors and mechanical vibration, published in Microsystems & Nanoengineering.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

Could this vibration based system also have the ability to affordably sooth and heal microcracks?