A group of scientists from the Tarbiat Modares University (TMU) in Iran has fabricated a brackish water reverse osmosis (BWRO) desalination unit integrated with a stand-alone hybrid photovoltaic-thermal (PVT) system which is claimed to produce freshwater at a cost that is close to that of conventional large-scale reverse osmosis (RO) desalination plants. Brackish water is water with salinity levels between seawater and freshwater and can usually be found in estuaries, where seawater and freshwater mix.

“We have fabricated a research scale setup and then evaluated it under the climate conditions of Tehran, Iran,” research co-author, Shiva Gorjian, told pv magazine. “The total cost of the current system considering the labor cost has been calculated as $779.50, but this is a research-scale set-up; for a commercial one the costs will definitely be reduced.”

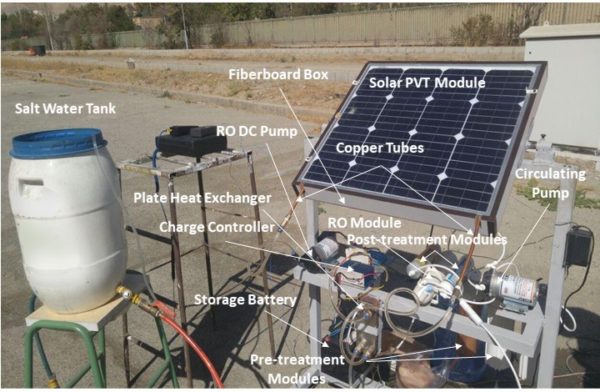

The BWRO unit, which has a treated water production capacity of around 11.80 L/h, was built with a pre-filtration module, a high-pressure DC pump, an RO module, and a post-treatment module. As for the PVT system, it was sized to meet the energy requirement of a high-pressure DC pump and a diaphragm-type circulation pump utilized to circulate soft water beneath the PV module for the active cooling of the panel itself. Two DC-DC converters of 10 A and 180 W of power were used to connect the loads to a battery.

“Since the efficiency of converters is not 100%, the battery was chosen in a way to supply the required power of the loads and compensate for the converters’ power losses,” the Iranian group specified. The PV module has dimensions of 676 x 700 x 30 mm, an output of 60 W, an open-circuit voltage of 21.5 V, and a short-circuit current of 3.88 A. The battery has a size of 92.8 x 65 × 20.2 mm and a nominal system voltage of 12 V.

The PV module was hybridized with the addition of a copper plate heat exchanger (PHE) with a capacity of 23.26 kW installed on its rear side to transfer the produced heat in the panel itself to the saltwater. A temperature control unit containing and a thermostat are used to control the temperature of soft water flowing out of the PVT module.

Popular content

The PVT-BRWO system was tested for eight days during October 2019. The measurements considered air temperature, total solar radiation, wind speed, boiler feed water (BFW) temperature, PV module’s surface temperature, and circulating soft water temperature. This analysis showed that weather data directly affect the operational parameters of the PVT module and, as a result, the productivity of the whole system.

Image: Tarbiat Modares University (TMU)

The average treated water production of the system treating 5,000 parts per million (ppm) and 15,000 ppm is 41.40 and 34.80 kg per day, respectively. “The treated water production cost of the unit treating 15,000 ppm salinity feed water was 18.96% higher than the unit treating 5,000 ppm salinity for all cases,” the academics explained. “The maximum treated water production cost of the unit was about 0.013 $/L, which is closer to the price associated with conventional fossil fuel-powered RO units (0.011 US$/L) and cheaper than passive solar still (0.041 US$/L) and solar membrane distillation units (0.017 US$/L).”

The payback time for the system is estimated between seven and 14 years, depending on several variables, including the price at which water is sold.

A thorough description of the system can be found in the paper “Performance evaluation and economics of a locally-made stand-alone hybrid photovoltaic-thermal brackish water reverse osmosis unit,” published in Cleaner Engineering and Technology.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.