Though promising in terms of energy density and charge-discharge cyclability, the performance of all-solid-state lithium batteries is undermined by significant resistance at the interface between the solid electrolyte and positive electrode. While the origin of the electrical resistance has not been fully determined, it is well known it increases more than tenfold when the electrode surface is exposed to air.

Several attempts have been made to lower such resistance but none have managed to bring it down to the 10Ωcm2 (ohm centimeter-squared) interface resistance value of devices which are not exposed to air. Now, researchers from Japanese bodies the Tokyo Institute of Technology, the National Institute of Advanced Industrial Science and Technology, and Yamagata University have reported promising results and demonstrated a drastic reduction of electrical resistance is achievable by annealing entire battery cells.

As part of pv magazine’s UP Initiative, we have focused on raw material sourcing in the energy storage industry. Read about material sourcing for batteries, lithium extraction in Chile, cobalt from the Congo, and the development of raw material recycling, and contact up@pv-magazine.com to find out more.Raw material sourcing

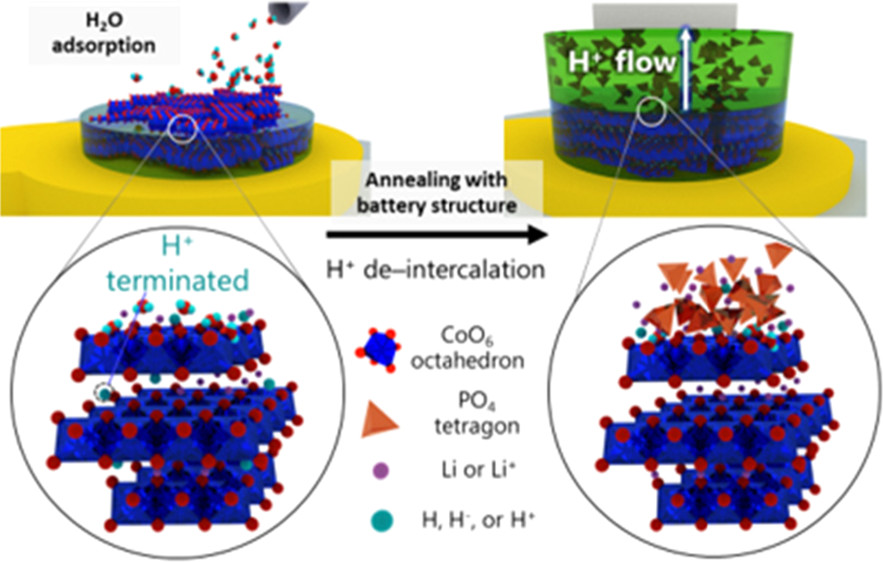

The team prepared thin film batteries comprising a lithium negative electrode, an LiCoO2 positive electrode, and an Li3PO4 solid electrolyte. Before completing fabrication of a battery, they exposed the LiCoO2 surface to air, nitrogen (N2), oxygen (O2), carbon dioxide (CO2), hydrogen (H2), and water vapor (H2O) for 30 minutes.

The researchers found exposure to N2, O2, CO2, and H2, did not degrade battery performance compared to a non-exposed battery. “Only H2O vapor strongly degrades the Li3PO4-LiCoO2 interface and increases its resistance drastically to a value more than 10 times higher than that of the unexposed interface,” said Taro Hitosugi, from Tokyo Tech.

Popular content

The team then performed annealing, with a sample undergoing a heat treatment at 150 degrees Celsius for an hour in battery form: with the negative electrode deposited. As a result, resistance was reduced to the initial 10.3Ωcm2. Simulations and measurements revealed the reduction could be attributed to the spontaneous removal of protons from within the LiCoO2 structure during annealing.

“Our study shows that protons in the LiCoO2 structure play an important role in the recovery process. We hope that the elucidation of these interfacial microscopic processes would help widen the application potential of all-solid-state batteries,” said Hitosugi.

The results are described in the paper “Drastic Reduction of the Solid Electrolyte–Electrode Interface Resistance via Annealing in Battery Form,” published in ACS Publications.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.