Silver bismuth sulfide (AgBiS2) nanocrystals (NCs) are an earth-abundant material that has been used in recent years as a promising PV material, often in combination with cadmium sulfide in the development of several kinds of ultra-thin solar cells.

Solar cells built with these nanocrystals have so far reached efficiencies of up to 6% and their optoelectronic overall properties have been found to change drastically as their composition and size are changed. Their fabrication can be performed in air at low temperatures using low-cost solution processing techniques and inexpensive production equipment. Furthermore, AgBiS2 NCs have very low toxicity compared to other materials used for thin-film solar cells, such as cadmium telluride and cadmium sulfide itself.

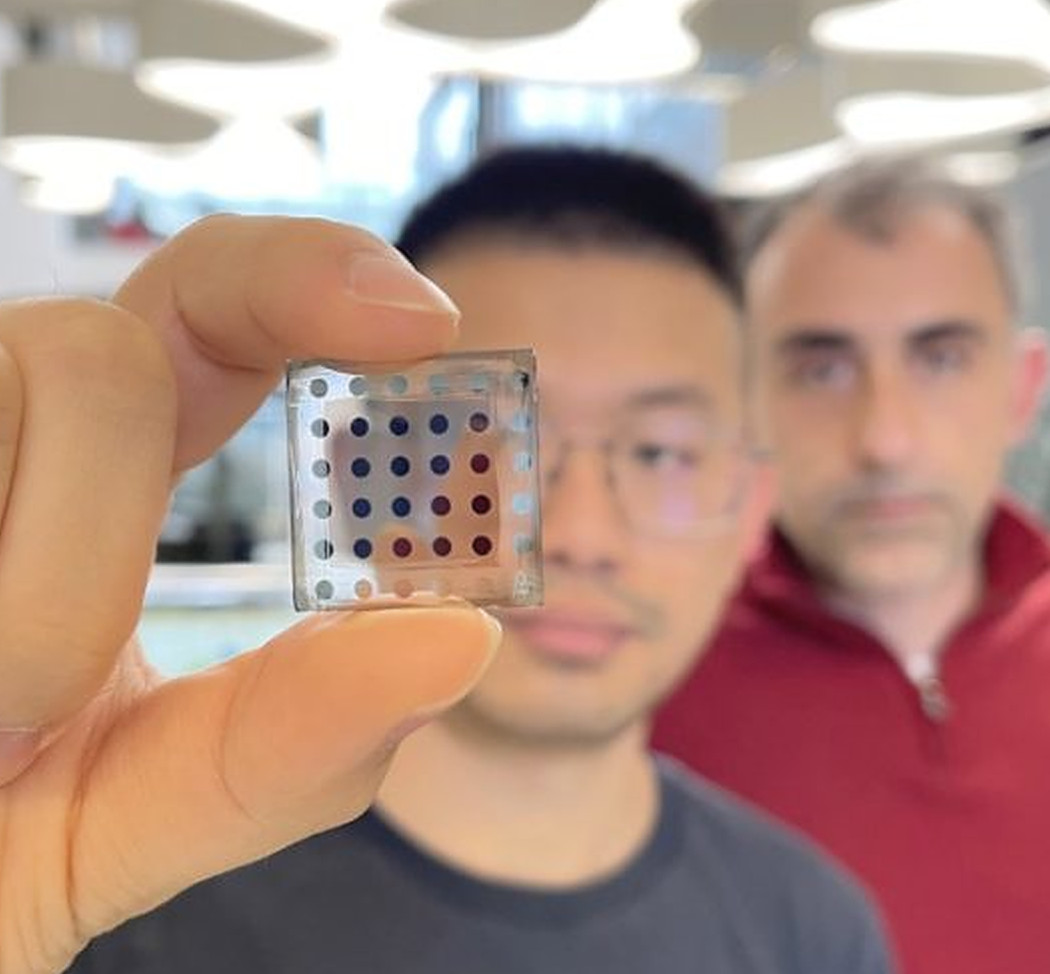

With this in mind, a group of researchers from the Institute of Photonic Sciences in Spain has developed an AgBiS2 PV device with potential applications in building-integrated photovoltaics (BIPV), vehicle-integrated solar, and internet of things (IoT) devices.

“Currently, this technology could have applications where environmental friendliness and compatibility with restrictions on hazardous substances is a big problem, like in consumer electronics,” the research's corresponding author, Gerasimos Konstantatos, told pv magazine. “It could also find applications where form factor is an issue so, in cases where low weight and flexible PV are needed and, as the performance may improve, this technology could even outcompete crystalline silicon photovoltaics in large scale applications.”

The scientists used a low-energy and scalable annealing process to produce an AgBiS2 material with an absorption coefficient that is claimed to be 5-10 times greater than any other material currently used for PV technology, across a wide spectral range from 400 to 1,000nm. “With the high absorption coefficient of our films, an ultra-thin layer of AgBiS2 NCs would be sufficient to absorb most of the light in the visible range,” they stated.

The researchers engineered the layer of nanocrystals in the cell with an unconventional approach described as cation disorder engineering, through which they tuned the atomic positions of the cations within the lattice of AgBiS2 nanocrystals to trigger a cation inter-site exchange and achieve a homogenous cation distribution. Mercaptopropionic acid was used as a passivating ligand to preserve the material quality upon annealing. “Our theoretical investigations of the thermodynamics and optical/electronic effects of cation disorder in AgBiS2 revealed both the accessibility of cation re-distribution and the strong impact of this on the optoelectronic properties,” said research co-author Seán Kavanagh. “Our calculations revealed that a homogeneous cation distribution would yield optimal solar cell performance in these disordered materials, corroborating the experimental discoveries as a testament of the synergism between theory and experiment.”

The solar cell was built with AgBiS2 nanocrystals that were deposited layer-by-layer onto a substrate made of glass and indium tin oxide (ITO). It was then coated with a solution based on poly(triaryl)amine (PTAA), which is an excellent hole transporting and electron blocking material.

Tested under standard illumination conditions the device achieved a power conversion efficiency of 9.17%, an open-circuit voltage of 0.495V, a short-circuit current of 26.75mA/cm2, and a fill factor of 63%. “It is really exciting to see that 30nm device gives such a high short-circuit current density up to 27mA/cm2 and an efficiency up to 9%,” said research co-author Yongjie Wang. “After grasping control of the process and optimization of the full stack, including optimizing electron and hole transport layers, we finally found a highly reproducible structure for efficient solar cells with improved stability.”

According to Konstantatos, the proposed manufacturing process is compatible with roll-to-roll techniques like those used for organic and perovskite cells and may be immediately reproducible on an industrial scale. “The cost related to the absorbers is only a fraction of the cost of the cell,” he told pv magazine. “The material cost is less than $10/m2 whereas the total estimated cost of the cell is around $120/m2. The biggest cost component is the encapsulation technology needed for all these types of thin-film PV devices and, with improvements on this, the total cost is envisioned to drop even more.”

The solar cell was described in the paper “Cation disorder engineering yields AgBiS2 nanocrystals with enhanced optical absorption for efficient ultrathin solar cells,” published in nature.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

3 comments

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.