From pv magazine France

Grenoble-based company Rosi Solar has developed a novel solution for recycling and reusing raw materials from the photovoltaic industry.

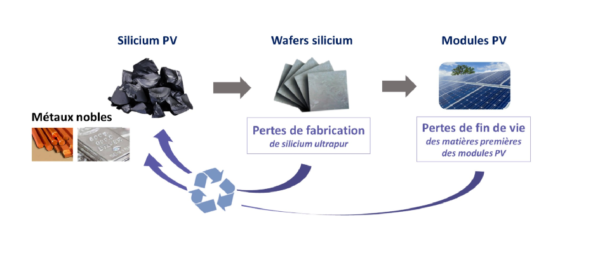

In particular, the start-up has set up a thermal and chemical separation process to recover ultra-pure silicon and other metals lost during the production of photovoltaic cells and at the end of the life of solar panels.

Rosi Solar was launched in 2017 and, since then, it has attracted the interest of many companies and institutions that now support it: French environment and energy agency Ademe, the French national investment bank BPIFrance, French environmental services provider Veolia, and European Union programs in particular.

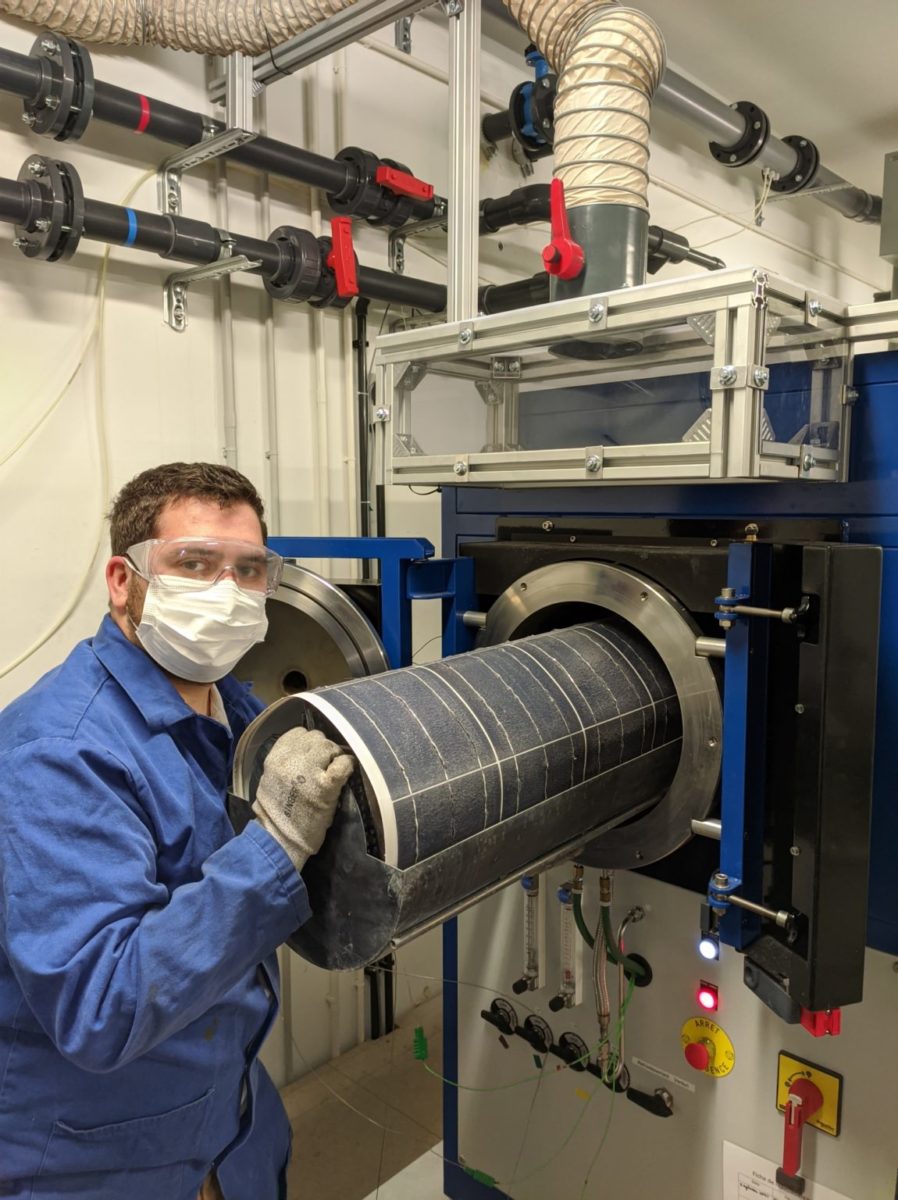

The company's technology is based on a pyrolysis process that makes it possible to isolate the different metals from the cells. Pyrolysis is generally used for temperature decomposition of organic material in the absence of oxygen. This process is known to provide excellent rate capability and high cycling stability. It is used in the chemical industry to produce ethylene, carbon and chemicals from petroleum, coal and even wood, in addition to producing coke from coal.

Image: Rosi Solar

“Silver represents less than 0.1% of the components of a solar module but it constitutes a big portion of its value,” Yun Luo, co-founder and president of Rosi Solar told pv magazine, noting that the same concept applies, to a lesser extent, to silicon, copper or even glass when it is of superior quality, or rather, high purity. “Our innovative process separates the metals and cells in a way that retains the purity of the material,” she stated.

Rosi Solar has not worked only on the development of a mild thermal and chemical treatment allowing the extraction of high-value metals and materials but also on the process, now patented, for the reintegration of silicon into different industries. Supported by Ademe for the proof of concept, the company utilized the results of its own research to carry out the purification of silicon, “in particular, from those of our first project, focused on the quality of the silicon recovered from the scrap resulting from the cutting of the wafers,” explained Luo. In 2019, the second extraction project was carried out in collaboration with Veolia for the proof of concept, and with Ademe for the co-financing of the industrial prototype. Rosi Solar's customers are all potential users of these materials, particularly in the chemical industry.

After several years of research and partnerships the company is now moving to the industrial deployment of its low-environmental impact recycling solution. With national players and, often, within European initiatives, it aims to promote its technologies for the purification of silicon and silver from used PV cells so as to create a market around the recovery of high-purity materials in the solar industry.

In France, its breakthrough technology, associated with the logistics and pre-processing services of Envie 2E Aquitaine, was selected by Sorem in July 2021 in a call for tenders to upgrade end-of-life photovoltaic (PV) modules. In its new plant at La Mure in Isère, the company will process laminates without glass, to extract silicon and metals. “This is our first major commercial contract,” said Luo, adding that the construction of the site began in July 2021, for commissioning planned by the fourth quarter of 2022. Eventually, the plant could recycle around 3,000 tons of solar panels per year, which corresponds to about three tons of silver and 90 tons of silicon.

In Germany, Rosi Solar is participating in the ReProSolar project led by a Veolia subsidiary in Germany, with the participation of Flaxres, Evonik, Technalia, and the French National Center for Scientific Research, which aims to separate, for the first time, all the components of PV modules in order to demonstrate the challenge of high value-added recycling of solar panels on an industrial scale. The EU is notably supporting the project with a contribution of €4.8 million via EIT Rawmaterials, which aims to significantly enhance innovation in the raw materials sector by sharing knowledge, information and expertise.

“We are at the beginning of a tsunami with regard to the PV module recycling market,” explained Luo, who foresees growth.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

4 comments

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.