Scientists from the Nanyang Technological University (NTU) and Singapore’s Agency for Science, Technology and Research (A*STAR) have developed a new way to synthesize the capping layer of perovskite solar cells without using lead.

“This paves the way for the development of eco-friendly perovskite solar cells that are one step closer to the consumer market,” an NTU spokesperson told pv magazine. “The findings unlock new opportunities for developing superior materials for the capping layer, for more efficient and stable perovskite solar cells.”

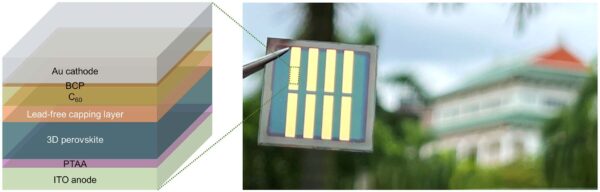

The capping layer of perovskite cells is usually fabricated using the half precursor (HP) method, where a chemical precursor is deposited on top of the perovskite layer. The precursor reacts with the lead ions present on the perovskite layer and forms a lead-based chemical compound that makes up the capping layer.

To make perovskite solar cells more environmentally friendly, the NTU scientists developed a new method known as the full precursor (FP) solution. They coated perovskites with solutions containing metal halide salts and phenethylammonium iodide (PEAI).

“PEAI contains ammonium, a positively charged ion that contains nitrogen and hydrogen, which is vital for the chemical reaction,” NTU explained in a statement.

The team synthesized a zinc-based compound known as PEA2ZnX4 using the FP method and found that it was the most effective capping material among the other materials tested. They then created a prototype solar cell capped with the zinc-based compound.

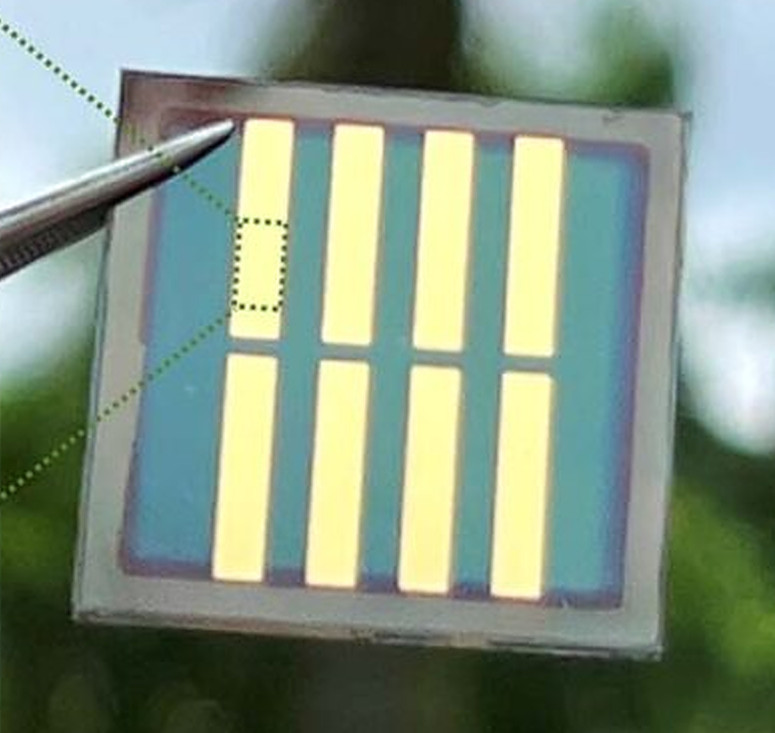

Image: NTU

“Unlike the HP method, there is no need to draw lead ions up from the underlying perovskite layer to form this protective capping layer when the FP method is used. This paves the way for the use of non-toxic metals in the capping layer,” said the scientists.

The perovskite cell reportedly has a conversion efficiency of 24.1% under lab settings. The prototype demonstrated an average light conversion rate of almost 23% over 103 cells tested. It maintained more than 90% of its ability to convert light into electricity for more than 1,000 hours of operation at full capacity.

The scientists are working on scaling up the method to fabricate full-sized solar cells. They are also in the process of filing a patent with NTUitive, NTU Singapore’s innovation and enterprise company.

They shared their findings in “Expanding the low-dimensional interface engineering toolbox for efficient perovskite solar cells,” which was recently published in Nature Energy.

*This article was updated on 21/03/2023 with a change of title from “Lead-free perovskite solar cell achieves 24.1% efficiency” to “Paving the way for lead-free perovskite solar cells”. The previous title was inaccurate because although the capping layer is lead-free, the prototype solar cell still uses lead-based perovskites. This information wasn't clear from the materials originally made available to pv magazine. We followed up with the authors after the mistake was pointed out by a reader. Here's a statement from the scientists: “Our method can be used with lead-free perovskites, which opens the possibility of lead-free perovskite solar cells. But for the prototype solar cell that we created in our paper, we still used the lead-based perovskites, and only lead-free materials in its capping layer.”

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

The headline of this article is deceiving at best. They did not make a lead free solar cell. One of the layers was simply lead free, as is the case with most of the layers in perovskite cells even before this article was published. The absorber material still has lead. A 1000hr stable, 24.1% efficient lead free perovskite solar cell would, indeed, truly be a break through. But it’s not even what the authors are claiming in their article. As a scientist myself, it’s frustrating to see journalists blow the actual scientific finding out of proportion. Our non-scientists friends and family ask if the discover is really as big of a deal as was made in main stream press and we have to say no and here’s why and then confidence in the press is eroded. Please stick to headlines and writing that highlight the real scientific discovery and rather than choosing “click bait” titles that don’t represent the truth. Thanks.

Hi Ashley, it wasn’t clear from the press release we received and subsequent communication that only the capping layer is lead-free. I’ve followed up with the authors after reading your comment and they’ve clarified with the following statement: “Our method can be used with lead-free perovskites, which opens the possibility of lead-free perovskite solar cells. But for the prototype solar cell that we created in our paper, we still used the lead-based perovskites and only lead-free materials in its capping layer.” I have now updated the article. It is never our intention to deceive, but mistakes do sometimes happen. Thanks for your understanding.