From pv magazine India

India’s Trinano Technologies has developed nanocoatings for solar modules that can increase their power output by up to 4% and lower the temperature by up to 3 C compared to non-coated panels.

“This means a 10 MW solar power plant with nanocoated panels would generate additional power of 720 MWh and thus an additional revenue,” Trinano Technologies CEO Harsh Sethi told pv magazine.

The nanocoating is environmentally friendly and chemically stable. It is designed to improve light trapping, anti-reflection, and self-cleaning properties.

“Besides increasing the panel’s energy output, these help in anti-soiling and reducing potential-induced degradation (PID). The coating can last for more than five years and reduces panel maintenance and cleaning (especially water-based) costs,” said Sethi, noting that the Thus, the return on investment is about two years.

The nanocoatings underwent extensive testing in research universities and labs in India and Thailand, confirming the improvements in panel output and temperature by the National Center for Photovoltaic Research and Education (NCPRE), IIT Bombay, which has technology and R&D collaborations with USA's National Renewable Energy Laboratory, Germany's Fraunhofer, and Australia's University of New South Wales.

Popular content

Similar results were observed at the National Institute of Solar Energy (NISE) in Gurugram, as well as in pilot projects conducted at Toyota's rooftop solar project in Mumbai, a residential rooftop solar plant in Navi Mumbai, and a Tata Power pilot project in Bengaluru.

The technology's patent application has been submitted in India and other member countries of the Patent Cooperation Treaty (PCT), with expectations of its grant by 2023.

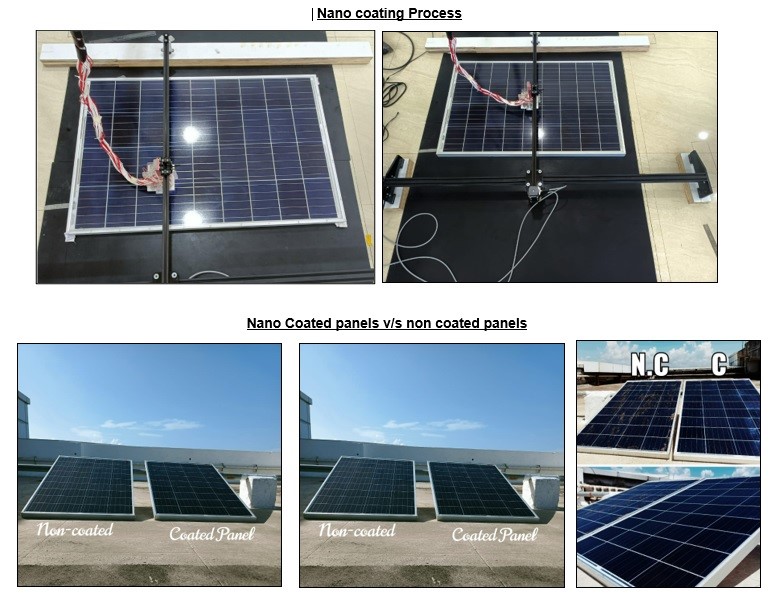

The coating process, performed with a portable coating machine and 6 kg frames, allows for application on existing panels without their removal from service. It involves solid-phase deposition without the use of liquid. In contrast, commercially available coatings, made of organic materials, are liquid and applied using paint, brush, or spray methods, but they decompose and deteriorate within two years.

The nanocoatings are suitable for monocrystalline, polycrystalline, and thin-film solar panels in both ground-mount and rooftop applications. Potential customers include solar panel manufacturers and solar plant owners.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

1 comment

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.