EneCoat Technologies, a Kyoto University PV technology spinoff, and Toyota Motor said they will team up on developing perovskite solar cells for applications in vehicle-integrated photovoltaics (VIPV).

“The two companies will continue to promote the development of practical applications by integrating EneCoat's elemental technologies for perovskite solar cells and Toyota's in-vehicle technologies for solar panels, with the aim of promoting self-sufficiency in renewable energy and contributing to the achievement of carbon neutrality,” the two companies said in a statement.

EneCoat said Toyota will use the cells it develops and produces with a proprietary deposition technology that enabled the production of a perovskite module with an efficiency of 19.4% as of March 2023.

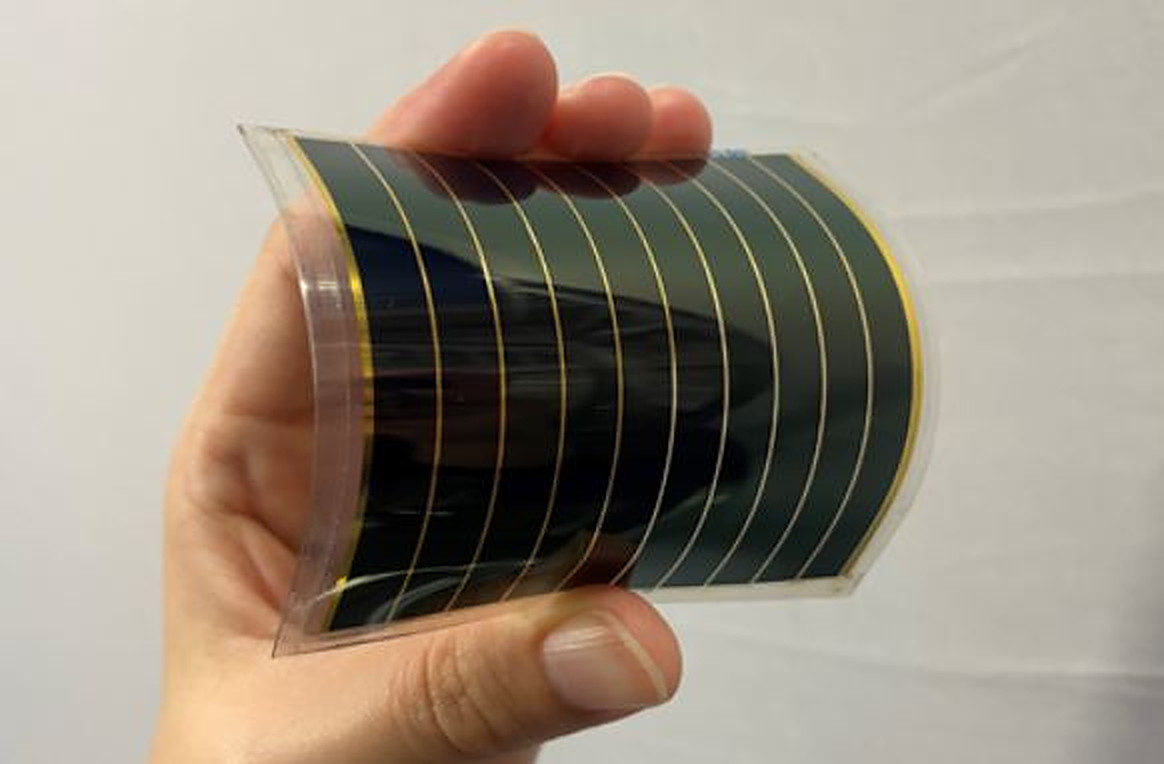

“Using a low-temperature coating process, it is possible to create a highly uniform ultrathin film as shown in the figure,” the company said. “Taking advantage of the wet process makes large area surfaces suitable for mass production, we plan to move forward with Roll to Roll production that can be tailored to the application and scale in the future.”

Popular content

In April 2022, NGK Insulators, a Japanese network-attached storage (NAS) storage specialist, acquired an unspecified stake in EneCoat. Japan-based Green Science Alliance, which specializes in the development of electrode materials for solar cells, also invested an unspecified sum in Enecoat in June.

Toyota said in March that it had selected Japanese solar manufacturer Kaneka as a supplier for solar cell deployment in one of its electric vehicles. Kaneka's solar cels have been for years recognized as the most efficient crystalline silicon PV device developed at both the industry and research levels.

However, Chinese manufacturer Longi said last November that it had crossed reached a power conversion efficiency of 26.81% with an unspecified heterojunction (HJT) solar cell, based on a full-size silicon wafer, in mass production.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

Toyota – a company that will do the right thing, eventually, having tried every dumb alternative first. Instead of just embracing the BEV technology, like the rest of the car industry, it tries to develop the dead-end hydrogen fuel cell technology, then the even dumber hydrogen ICE, now, with GAC it’s pushing ammonia ICE. So not surprising that it’s developing perovskite PV because what better way to destroy the environment than to contaminate it with lead. They don’t say in this article, of course, but you can be sure the halide being used in these PV cells contains elemental lead which will cause an environmental headache.