From pv magazine USA

Perovskite technology startup Caelux announced it has secured a series A funding of $12 million, bringing total funding to $24 million to develop and commercialize its perovskite glass for tandem use. The company will open a 100 MW perovskite-glass manufacturing facility outside of Los Angeles, California.

Caelux said tandem cells using its technology can push efficiencies past 30%, while retaining the same cost per Watt.

Perovskites are under focus for many global research teams as an abundant, highly efficient photovoltaic material, but they suffer from resilience and lifecycle limitations. New records of efficiency and stability are continually being demonstrated in laboratories, moving the technology closer to commercialization.

Caelux is among first movers on this road to commercialization as it netted the new Series A fund in a round led by Temasek with participation Reliance New Energy, Khosla Ventures, Mitsui Fudosan and Fine Structure Ventures.

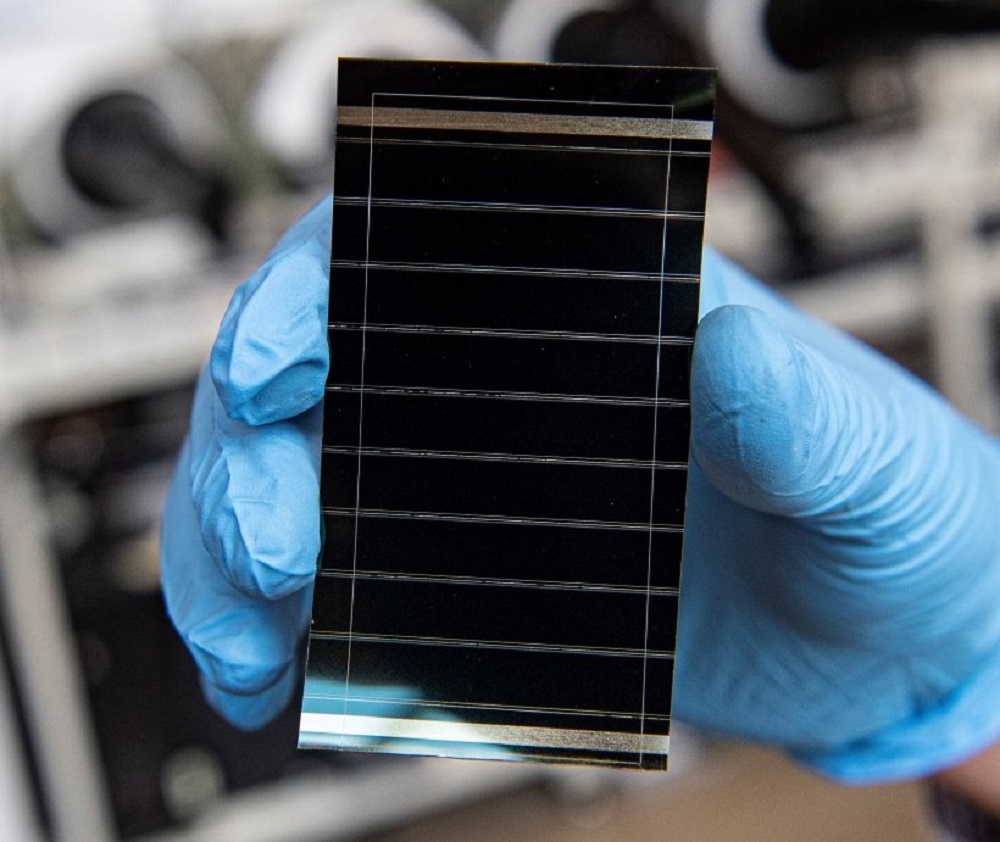

The company has developed a method for depositing a perovskite layer in glass, enabling it to be readily integrated with existing solar cell manufacturing lines for a boost in module output. Caelux said its solar glass alone offers greater than 17% efficiency, and when deposited in tandem with other cell technologies, it can boost the overall conversion efficiency rating by six percentage points.

Caelux said its perovskite glass layer can be deposited in existing manufacturing processes with minimal changes to the facility. It is technology-agnostic, allowing for integration with all conventional cell technologies, including PERC, HJT and TopCon.

Popular content

“This investment will support our mission to usher in the next generation of solar innovation, including our production of full-size perovskite sub-modules,” said Scott Graybeal, chief executive officer, Caelux. “We are excited to have attracted visionary, global investors to help us on our journey to multi-gigawatt scale.”

The company said its U.S.-made perovskite-glass sub-module, called Caelux One, qualifies as a solar cell under Treasury Department analysis, making it eligible for manufacturing tax credits as well as contributing to a project’s domestic content percentage.

pv magazine print edition

In the latest, “In Conversation” issue of pv magazine we talk to a range of people about their experience with solar, from a sailor and a pair of overland adventurers to a mountain climber and more besides. We also focus on Africa to consider why a continent with such vast solar resource still lags more developed economies when it comes to widespread PV and energy storage rollout.

“Companies should be incentivized to scoop us up into part of their manufacturing value chain, because now they have a solar cell that was produced right here in the United States,” said Leslie Chang, director of strategy and policy, Caelux in an interview with Solar Power World. “By incorporating Caelux, not only are you able to increase the overall power conversion efficiency of your module, but also you better qualify for these domestic content regulations.”

The company said it targets a commercial launch of Caelux One in 2024, with aims to secure Series B funding and reach gigawatt-scale production after launch.

In June, another U.S. manufacturer, CubicPV, secured equity commitments in excess of $100 million to scale a U.S. solar wafer production facility. Formed in 2021 in a merger of Hunt Perovskite Technologies and 1366 Technologies, the company has a history with perovskite development, and said it will continue its research and development of tandem modules as part of the funding led by SCG Cleanergy.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.