Livoltek commissions inverter factory in Brazil

The company opened an inverter factory in the Manaus Free Trade Zone with a capacity of 1.8 GW, or 300,000 units per year. In the second phase, it plans to bring in the production of hybrid inverters and lithium batteries as well as chargers for electric vehicles and motors for electric boats. The company will have distribution centers in Curitiba and Fortaleza to ensure rapid delivery of equipment to the domestic market, with a minimum warranty of 10 years.

Year-to-year solar variability peaks in Europe, Australia, Argentina, and China

In a new weekly update for pv magazine, Solcast, a DNV company, reports that the regions with the highest year-to-year variability in irradiance include Central and Northern Europe, East Coast Australia, Northern Argentina, and China, with Africa exhibiting the most stable irradiance year-on-year.

Insolation Energy to add 3 GW solar panel, 1.4 GW cell capacity by March

The Indian manufacturer is expanding its solar panel production capacity to 4 GW annually, up from a current 1 GW. It is also setting up manufacturing capacities for 12,000 MT of aluminum framing and 1.4 GW of PV cells. The new capacities will be commissioned during fiscal year 2024-25.

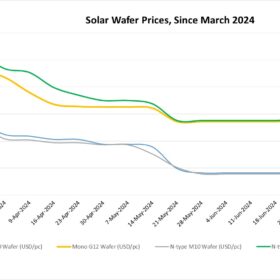

Wafer prices near bottom, size evolution and capacity globalization continue

In a new weekly update for pv magazine, OPIS, a Dow Jones company, provides a quick look at the main price trends in the global PV industry.

Researchers find agrivoltaics have LCOE of $0.039/kWh, 7-year payback time in India

Indian researchers have compared the performance of an agrivoltaic system to monofacial and bifacial rooftop PV systems, and have found that the agrivoltaics setup had a shorter payback time and lower levelized cost of energy. Their analysis of performance considered panel temperature, power output, land equivalent ratio, and reliability.

Critical mineral report highlights Australia’s solar panel recycling potential

A new report published by the CSIRO says Australia’s research into solar recycling is second in the world, outside China, but suggests the establishment of mid-stream activities such as the production of metallurgical silicon and polysilicon have big potential.

Heliene, Premier Energies announce U.S. solar cell factory

Heliene is a solar module provider operating in North America, while Premier Energies is the second largest solar cell manufacturer in India.

Sale process begins for German microinverter maker Solarnative

Solarnative launched insolvency proceedings and started searching for new investors in June.

US engineers develop ChatGPT algorithm to design solar cells

OptoGPT is a new algorithm that harnesses the computer architecture underpinning ChatGPT. Its creators say that it will enable researchers and engineers to design optical multilayer film structures for a wide range of applications, including solar cells.

Comal plans 500 MW solar module factory in Italy

Comal says it has acquired an industrial building near L’Aquila in central Italy for a 500 MW solar module factory. Production is scheduled to start in 2025.