A group of scientists led by the University of Sydney has fabricated a perovskite solar cell that utilizes a substrate made of steel instead of glass.

“The advantage of being flexible and conductive means the steel itself can act as both a substrate and an electrode for either large-area-monolithic-panel or smaller-area-singular single-junction or multi-junction cell fabrication,” the research's lead author, Anita Ho-Baillie, told pv magazine. She suggested that the cell could be used for building-integrated PV (BIPV), vehicle-integrated solar (VIPV), or other design-integrated photovoltaics for terrestrial or space applications.

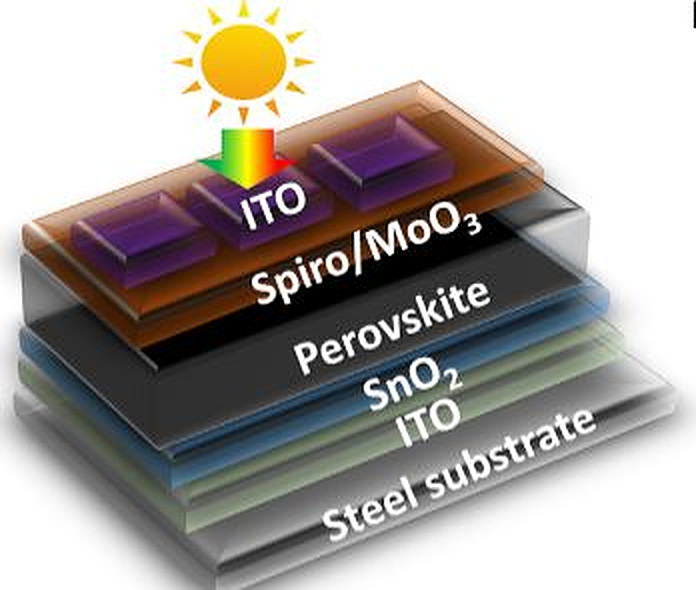

In the study “Efficient perovskite solar cell on steel enabled by diffusion barrier and surface passivation,” published in Cell Reports Physical Science, the researchers explained that steel is flexible and conductive while offering good thermal stability, strength, and toughness. It is, however, an opaque material, which makes it necessary to use a transparent electrode for the solar cell. To this end, the scientists used an indium tin oxide (ITO) interlayer between the steel substrate and the cell, in order to avoid iron diffusion from the substrate into the PV device.

They built the cell with the steel substrate, an 80-nm-thick ITO layer, a tin(IV) oxide (SnO2) electron transport layer, the perovskite absorber, a Spiro-OMeTAD hole-transporting layer, a buffer layer made of molybdenum trioxide (MoO3), and the ITO transparent electrode.

A first device constructed with this configuration achieved a power conversion efficiency of 13.2%, an open-circuit voltage of 1,072 mV, a short-circuit current density of 18.3 mA/cm2, and a fill factor of 0.67. A similar cell built without the ITO interlayer, by contrast, achieved an efficiency of only 6%, with the other values being 763 mV, 17.2 mA/cm2, and 0.46, respectively.

Popular content

“This work inspires future work where different materials as an interlayer could be investigated and where cells using materials with better refractive index matching can be demonstrated with the aim of further boosting the performance and stability of perovskite cells on steel,” the researchers stated.

Ho-Baillie added that no techno-economic analysis of the cells has been conducted to date. “We have done so for perovskite on glass, roll-to-roll manufacturing of perovskite cells, and silicon–perovskite tandem cells indicating cost competitiveness assuming the lifetime of perovskite cells can match that of the incumbent silicon cell technology,” she concluded.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

1 comment

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.