A group of researchers led by the Korea Institute of Material Science (KIMS) have developed a new optical technique to color flexible thin-film building-integrated and vehicle-integrated solar panels.

The proposed technology is reportedly able to exhibit different reflective colors and not significantly reduce solar cell efficiency. “We directly fabricated the cell using a transparent electrode based on hydrogenated aluminum doped zinc oxide (AZO) material and silicon thin film,” the research lead author, Jung-dae Kwon, told pv magazine.

The scientists also designed a multi-layer thin film with a refractive index difference of less than 5%, which they claim minimizes the reflection loss in the visible light region absorbed by the solar cell. “It can be applied to various absorbers for thin-film solar cells as it hardly reduces the solar cell efficiency due to color implementation,” they explained.

In the paper “Flexible multi-layered coloring transparent electrode composed of AZO–based materials,” published in Chemical Engineering Journal, the researchers explained that the hydrogenation of AZO causes passivation in vacancies of oxygen and zinc, strengthening the oxygen and hydrogen bonds, which delivers the desired electrical and optical properties.

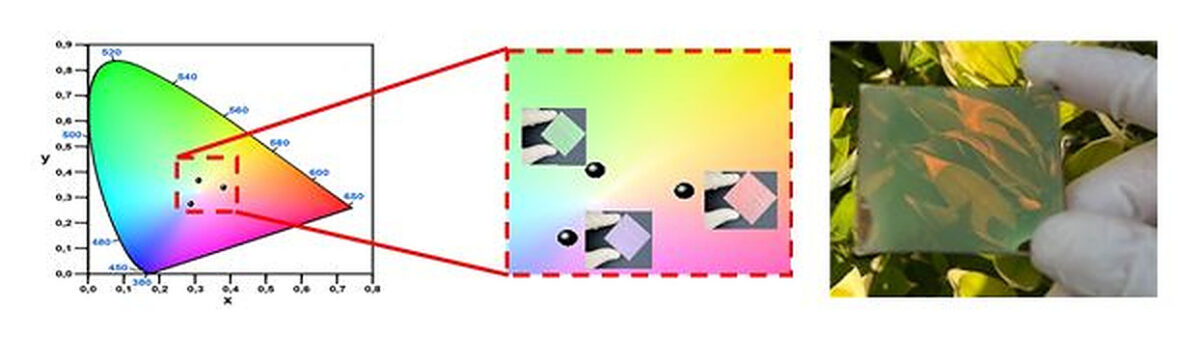

They tested their approach on a thin-film cell based on amorphous silicon (a-Si). To achieve all three primary colors, the team used conventional vacuum sputtering deposition to fabricate a distributed Bragg reflector (DBR) electrode made of six pairs of AZO and AZO:H on ultra-thin colorless polyimide.

The DBRs consist of alternating dielectric layers, commonly serving as reflectors and dielectric mirrors, and their multilayered composition alternates between high and low refractive indices, resulting in customizable reflection spectra.

The group stressed it was able to control color and conductivity by the thickness of the DBR layers, which they said resulted in little difference in power conversion efficiency for each color, excellent flexibility, and durability under bending stress. The best results were achieved with a green-colored prototype, which had a power conversion efficiency of 5.45%. The prototypes for all three colors withstood 600 cycles at a 6 mm bending radius. The power ratings were 1.14 W, 1.29 W, and 1.22 W per gram for blue, green, and red, respectively.

The researchers concluded that the methodology can be used for a variety of thin-film solar cells that require both color and flexibility in a low-cost process. Moreover, since the reflective color is implemented as an optical filter, it “can be applied to various fields such as image sensors, photolithography masks, and infrared shielding.

“We are still in the basic research stage, and commercialization will take time as there is no basis for large-area production,” Kwon concluded.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

awesome, this can create other forms of colored reflections