One of the major developments in the solar industry in 2023 is the unprecedented expansion of PV manufacturing currently underway in the United States. While there was 5 GW of US PV production in 2022, according to NREL, there have been some 70 GW of manufacturing capacity announcements made since the launch of the Inflation Reduction Act (IRA).

What is particularly noteworthy is that manufacturing in the United States is expanding further up the supply chain – from module assembly to PV cell production. Cell investment and production is both more capex intensive and technologically challenging. Given this, it makes sense for manufacturers to develop sophisticated technology roadmaps, in an attempt to future-proof their production facilities.

While Passivated Emitter Rear Cell (PERC) technology has been the workhorse of the modern solar industry, it is becoming increasingly clear that increases in mass production efficiencies are becoming more difficult to achieve. Recent reports have PERC cell efficiencies topping out at 23.3%. This is a confirmation that manufacturers have reached the technical limitations of PERC in terms of efficiency.

It should come as no surprise then that of the approximately 60 GW of new cell capacity added globally in Q2, the majority of it was in the form of new Tunnel Oxide Passivated Contact (TOPCon) lines. But what comes next?

Heterojunction (HJT) and Interdigitated Back Contact (IBC) cells are established technologies that can advance efficiencies beyond PERC. Looking further ahead, perovskite tandem PV cells represent a genuine “step change” cell technology, with efficiencies well beyond that of conventional PV cells.

In May 2023, perovskite tandem developer Oxford PV achieved an efficiency record of 28.6% on an M4-format cell – in a result verified by Germany’s Fraunhofer ISE. It is a remarkable achievement and points to a bright future for what Oxford PV terms “perovskite-on-silicon” tandem PV cells. However, scaling such devices to module or mini-module level introduces a range of new challenges, not least measuring the Stabilizing Power Output (SPO) of these devices.

Measurement challenges

As can be expected with a new technology, perovskite tandem cells and modules require a new approach when it comes to measurement and characterization. For the past five years, Eternal Sun has been working with the leading research institutes and early-stage companies in their development of perovskite tandem devices – including NREL, GCL nano, Kaust, QUT, Utmo Light, Microquanta, and others that can’t be disclosed.

Image: HHV

The unique measurement challenges posed by perovskite and perovskite-tandem PV devices are myriad. Eternal Sun plays a role in addressing these challenges and I serve as a member of the technical working groups that are developing the standards for perovskite device measurement. Here is an overview of the measurement challenges posed by PV perovskite measurement based on Eternal Sun’s work with prospective perovskite manufacturers and research institutes.

Accurate measurement of SPO in perovskite devices requires:

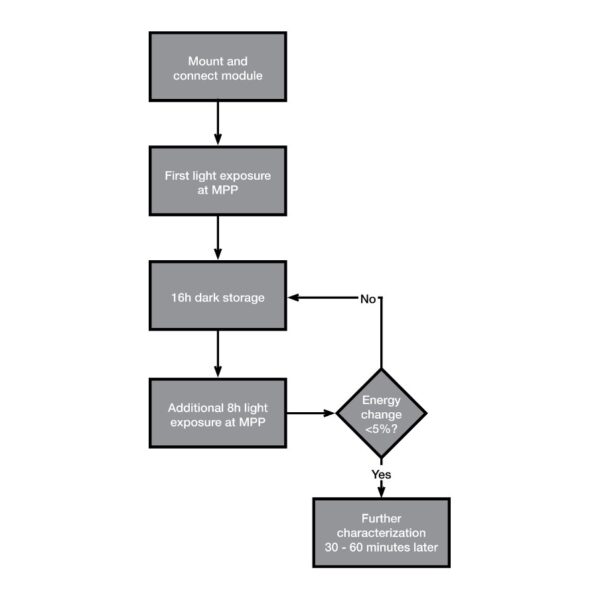

– Pre-conditioning of the device, through light soaking of approximately 2-10 minutes, to achieve stabilization.

– Multi Peak Power (MPP) tracking under continuous illumination – most commonly using the “Perturb and Observe” method at appropriate perturb and step intervals.

– Slow IV curve measurement, of approximately one minute, to measure stabilized output values (for Isc, Voc etc.) which can overcome hysteresis effects.

– Application of dark (night) cycles to produce an accurate module energy yield measurement.

– High level of temperature (<-4C) and light (<2%) uniformity, as variation can lead to significantly different measurement outcomes.

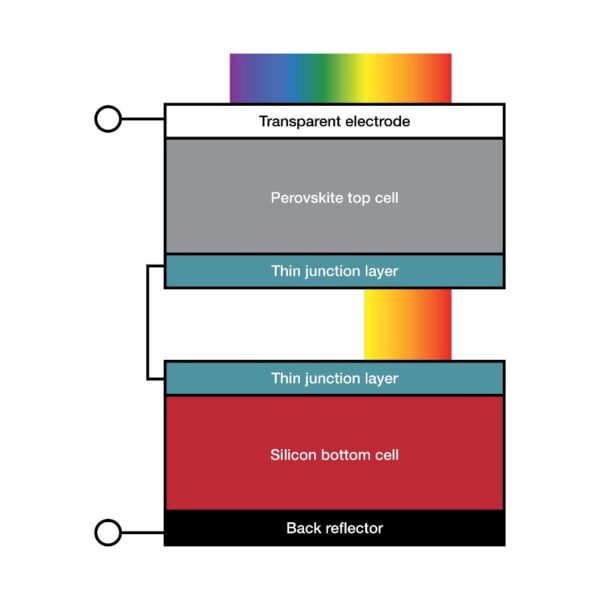

– Ability to calibrate the light source for perovskite tandem devices – particularly in the case of two-terminal cells (see Figure 1).

– Temperature control (25C), for tandems, to avoid the differing temperature coefficients of the semiconductor layers impacting accurate measurement.

Popular content

Image: Perovskite PV Accelerator for Commercializing Technologies (PACT)

In August, Eternal Sun hosted a webinar outlining these technical challenges and the latest developments in relevant standards, which can be accessed here.

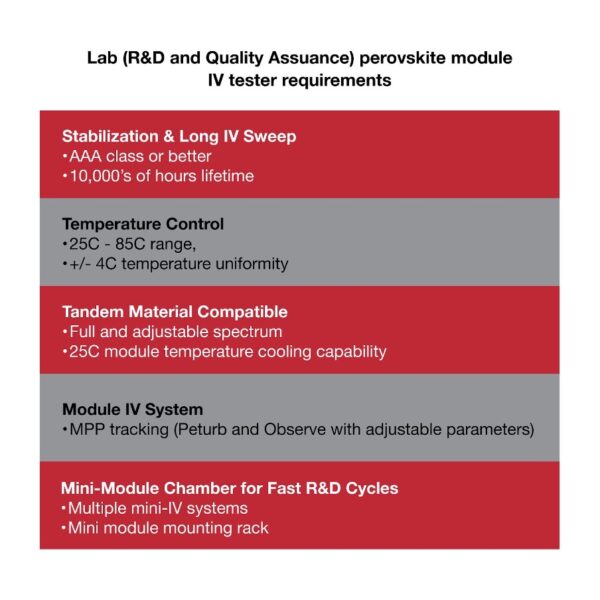

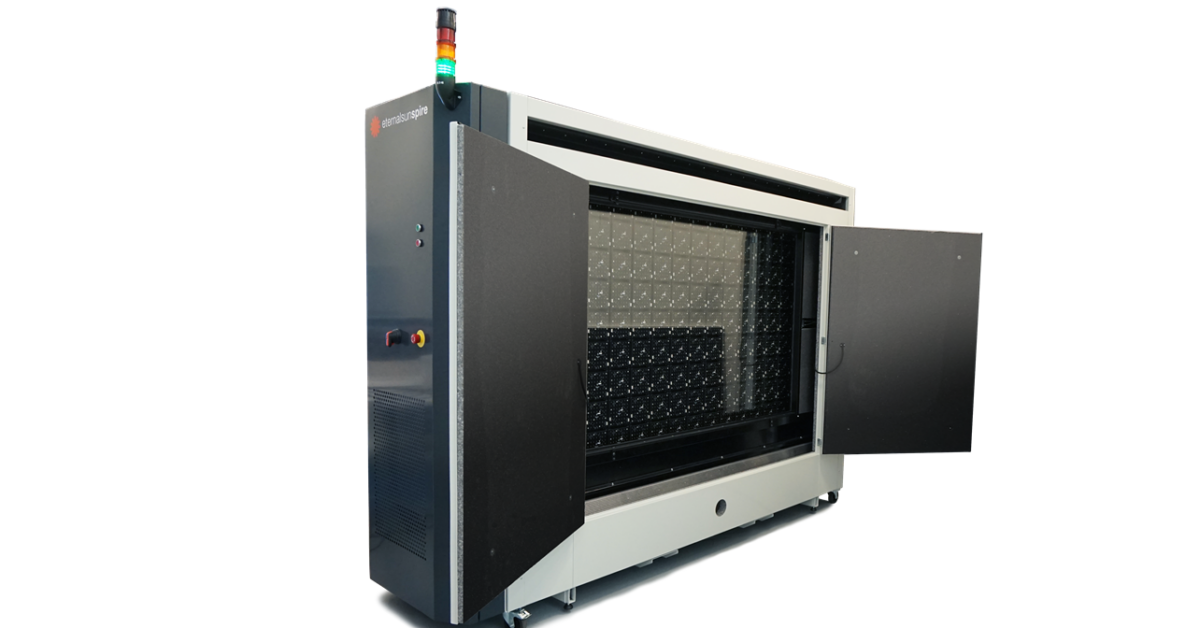

Given these requirements for accurate perovskite PV device and tandem device measurement Eternal Sun developed LED-based solar simulators in two sizes to facilitate the testing of individual devices or multiple modules. The measurement requirements of perovskite devices, outlined above, can be fulfilled by these steady-state solar simulators as listed in the table below.

Eternal Sun’s solar simulators for perovskite measurement have been adopted widely by research institutes and R&D laboratories. The installed base of Eternal Sun LED steady-state technology will exceed 100 tools by the end of 2024.

From lab to fab

Through the work of Eternal Sun experts, along with our industry and research colleagues, the development of industry standards for perovskite measurement is progressing well, namely the IEC TR 63228. And the good news is that industry norms are becoming clear and being adopted in the standard.

But that’s not to say that standardized measurement norms are locked in for testing in large scale production. The testing regime that is leading to the best SPO results includes testing times too long for mass production. It will presumably take some years of intensive work before an in-line regime, suitable for factories rather than laboratories, can be agreed on and adopted. Despite this, Eternal Sun believes that it is likely, as with the current practices for thin films, that a combination of 100% inline testing with offline, or sample, testing will yield reliable results.

Horses for courses

As their track record demonstrates, Eternal Sun LED sun simulators are proving crucial in the maturation of promising perovskite PV technology and in perovskite tandem devices. However, LED-based measurement equipment remains only a part of the Eternal Sun product portfolio.

Xenon-based solar simulators remain the “gold standard” in mass production at PV module manufacturing sites the world over. Xenon light sources continue to offer a full light spectrum, over 99% spectral coverage, to module makers at an attractive capex and opex.

Beyond the unique measurement challenges posed by perovskite technology, Xenon-based measurement equipment remains the trusted technology for leading solar research laboratories. Xenon is the accepted reference light source, and no lab is using only LEDs in their testing.

Eternal Sun’s range of Xenon-based equipment can chart its development back as far as 1980 – through Spire Solar, which Eternal Sun acquired in 2016. The company also has arguably the longest track record in the supply of devices with long, steady state illumination, a prerequisite for the measurement and testing of modules that deploy perovskite technology.

There is no doubt that PV perovskites and tandems deserve their place on the development pathway of solar manufacturers both new and established. The promise of 28%+ conversion efficiencies represents a major step towards solar seizing a place of primacy in the global energy economy. And accurate and reliable measurement will play a central role in this development.

Eternal Sun is currently developing a white paper exploring the latest in the use of LEDs in perovskite module measurement. Myself and other members of the Eternal Sun team will be on the ground in Las Vegas, for the RE+ show this week. Be sure to get in touch to find out how LED solar simulators can play a role in your company or research institute executing on their technology roadmaps.

About the author: Stefan Roest is a founder and the CTO of Eternal Sun Group. He discovered his passion for solar energy driving the Nuna4 solar car through the Australian outback, winning the 2007 World Solar Challenge. Stefan completed his master in PV technology at Delft University of Technology in the Netherlands (TUDelft). At the university, he invented a new large area steady-state solar simulator. Eternal Sun was founded as a spin-off from this project. In early 2016, the Eternal Sun Group acquired the sun simulator division of Spire Corporation. The company supplies steady-state and flash solar simulators to worldwide customers in solar R&D, certification and manufacturing.

The views and opinions expressed in this article are the author’s own, and do not necessarily reflect those held by pv magazine.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.