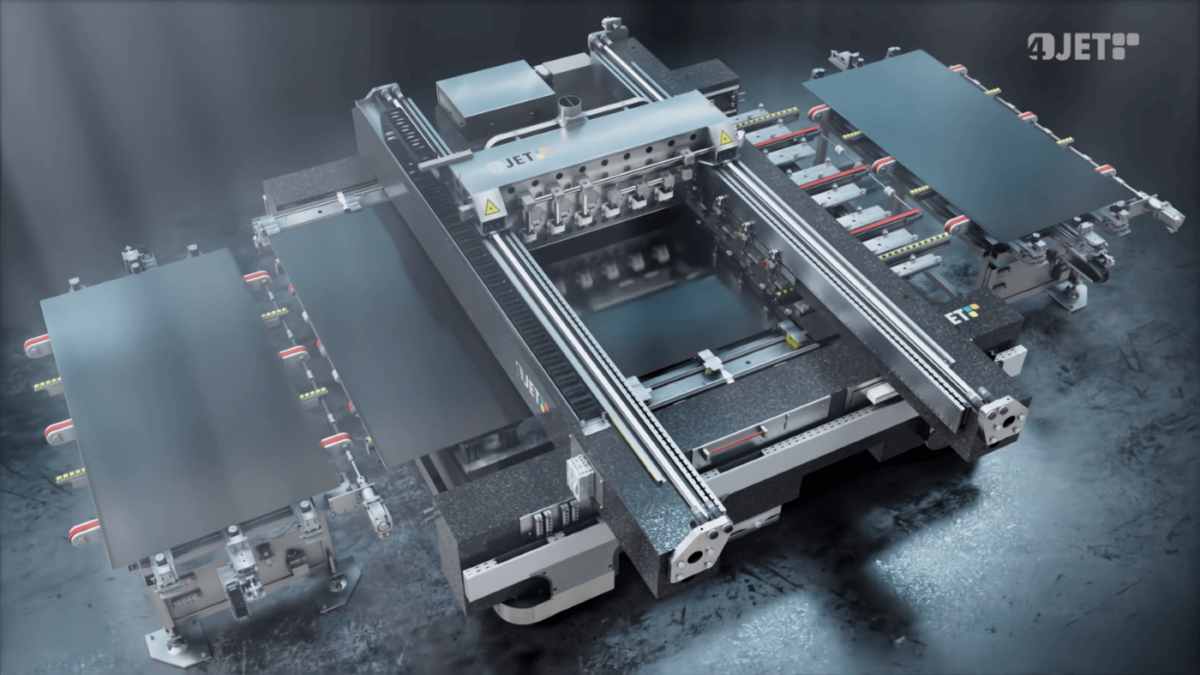

German equipment supplier 4JET unveiled a new laser system for thin film scribing.

Called TOPAZ P1/P2/P3, the new laser system can be equipped with a wide range of laser sources, including nanosecond, picosecond, and femtosecond lasers in the infrared, green or ultraviolet wavelength ranges from can be done from either the substrate-side or from the film-side. The company claims a throughput of greater than 10,000 substrates per day with 10-second cycle times for 300 scribe lines.

The working area is said to go up 2,400 mm x 1,300 mm, supporting substrate thickness in the range of 2 mm to 4 mm. “Customers can, of course, request specific dimensions within the working area range,” Benjamin Bopp, sales director at 4JET, told pv magazine.

The system has a laser sub-system design featuring “individual path tracking,” which Bopp said is related to the other features, such as individual auto-focus, and individual power-balancing for every single processing beam.

“In other concepts, there is only one sensor for a multitude of laser beams, for example, which causes inaccuracies by design. The laser beams from the source are split into multiple laser beams in the processing head. Since beam splitting is never perfect in real life, this leads to uneven power distribution, and therefore uneven scribing results,” said Bopp.

The laser units each have their own sensors, power level settings, and focus optics. These features result in more precise measurement and a higher number of measurement points, according to Bopp, which in turn means more precise, consistent scribing, and the potential to reduce unproductive areas between scribing lines, te so-called dead zones.

Popular content

According to the manufacturer, the system design has also the benefit of being able to bring the scribes closer together without increasing the risk of crossing, which leads to fewer inaccuracies in terms of focus position, and fade out lines, especially at the edges of the modules.

The new solution has a power requirement of 400Vac, 63 A and a factory-floor footprint of 7,500 mm³ x 5,650 mm³ x 2,300 mm³, including peripherals.

First customers are using the new systems in pilot line production with several systems on order for mass production purposes, according to Bopp.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.