An international research team has found that cadmium telluride (CdTe) solar cells had no cell delamination signs, nor deterioration in the short circuit current and series resistance after operating for almost six years on a satellite orbiting the Earth.

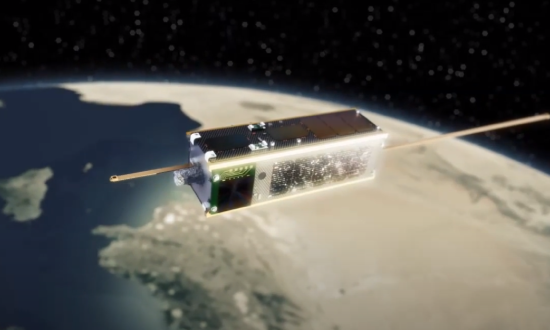

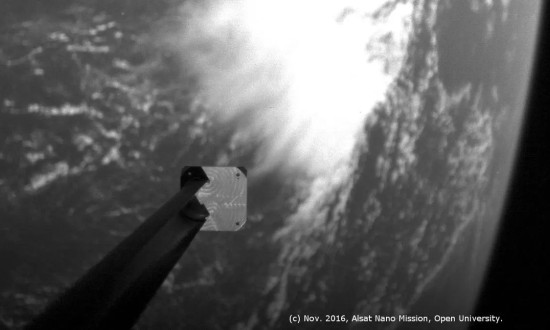

The scientists integrated the cells onto the AlSat-1N 3U CubeSat satellite, which was launched from India into a 661 km × 700 km orbit on September 26, 2016.

We are very pleased that a mission designed to last one year is still working after six,” said the research's lead author Craig Underwood. “These detailed data show the panels have resisted radiation and their thin-film structure has not deteriorated in the harsh thermal and vacuum conditions of space.

The researchers built the cells using an ultra-thin space-qualified cerium-doped alumino-silicate cover-glass developed by photonic products provider Qioptiq Space Technology (QST). They deposited the transparent conducting oxide (TCO) and thin-film CdTe layers onto this substrate via metal-organic chemical vapour deposition (MOCVD).

“The industry leader then and now, for CdTe manufacturing, is First Solar Inc. who utilize High-Rate Vapour Transport Deposition (HR VTD),” the academics emphasized. “It is assumed, by the authors, that any future large-scale adoption of CdTe directly on cover-glass would employ this HR VTD mature manufacturing process with its inherently lower production cost than MOCVD.”

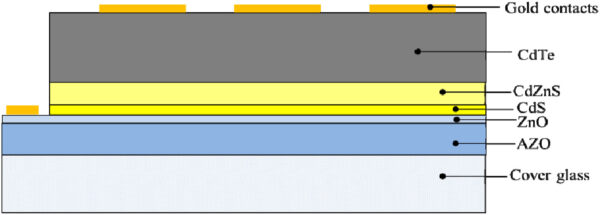

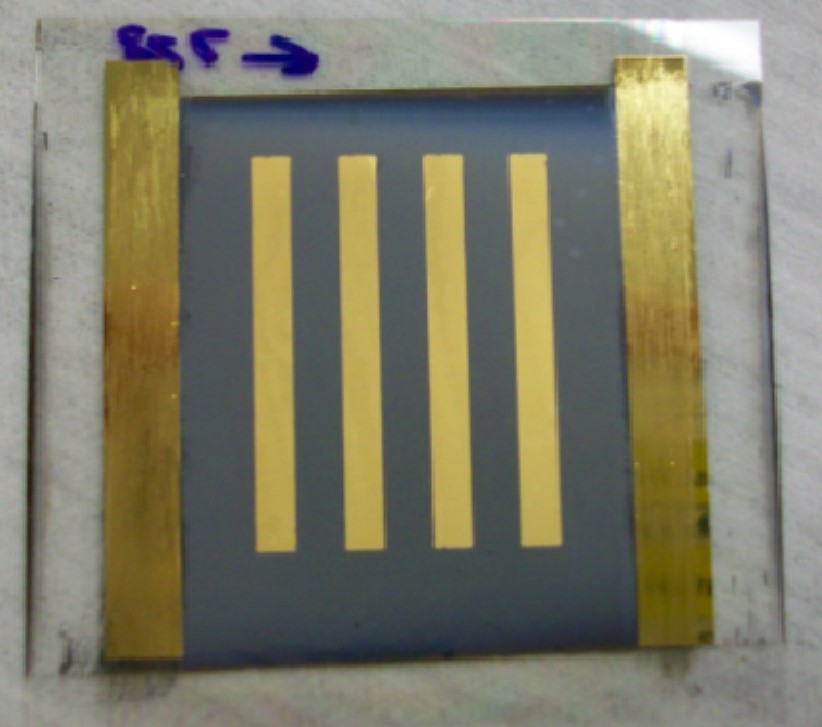

The cell was designed with an aluminium-doped zinc oxide (AZO) front contact, a zinc oxide high resistive transparent (HRT) layer, a cadmium zinc sulphide (Cd0.3Zn0.7S) n-type window layer, an arsenic-doped cadmium telluride (CdTe:As) p-type absorber, gold (Au) contacts, and a 100 μm thick QST glass.

Image: Swansea University, Acta Astronautica, Creative Commons License CC BY 4.0

Tested on earth, the cell achieved an average power conversion efficiency of 12.1%, an open-circuit current of 788 mV, a short-circuit current density of 28.0 mA·cm−2, and a fill factor of 76.4%.

Popular content

In orbit, the cells endured temperature cycling between +85 C and −40 C without significant change in performance or sign of delamination, according to the research team.

Their I–V measurements showed, however, that the devices suffered a significant degradation of shunt resistance. “We ascribe this to the diffusion of gold from the back contact into the CdTe layer forming micro-shunts along the grain boundaries,” they specified. “Any future demonstration of the CdTe TFSC technology will require a new back contact architecture to be developed to realise the true potential of these cells for spaceflight.”

Their results are presented in the paper “IAC-22-C3.3.8 Six years of spaceflight results from the AlSat-1N Thin-Film Solar Cell (TFSC) experiment,” published in Acta Astronautica. “The findings could pave the way for commercially viable solar farms in space,” the scientists stated.

The research team includes academics from the University of Surrey and Swansea University in the United Kingdom, as well as the Algerian Space Agency (ASAL). Scientists from the University of Surrey designed the instruments to measure the cell performance in orbit, while the Surrey Space Centre and the ASAL designed the satellite. Researchers from the University of Swansea's Centre for Solar Energy Research developed the CdTe cells.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.