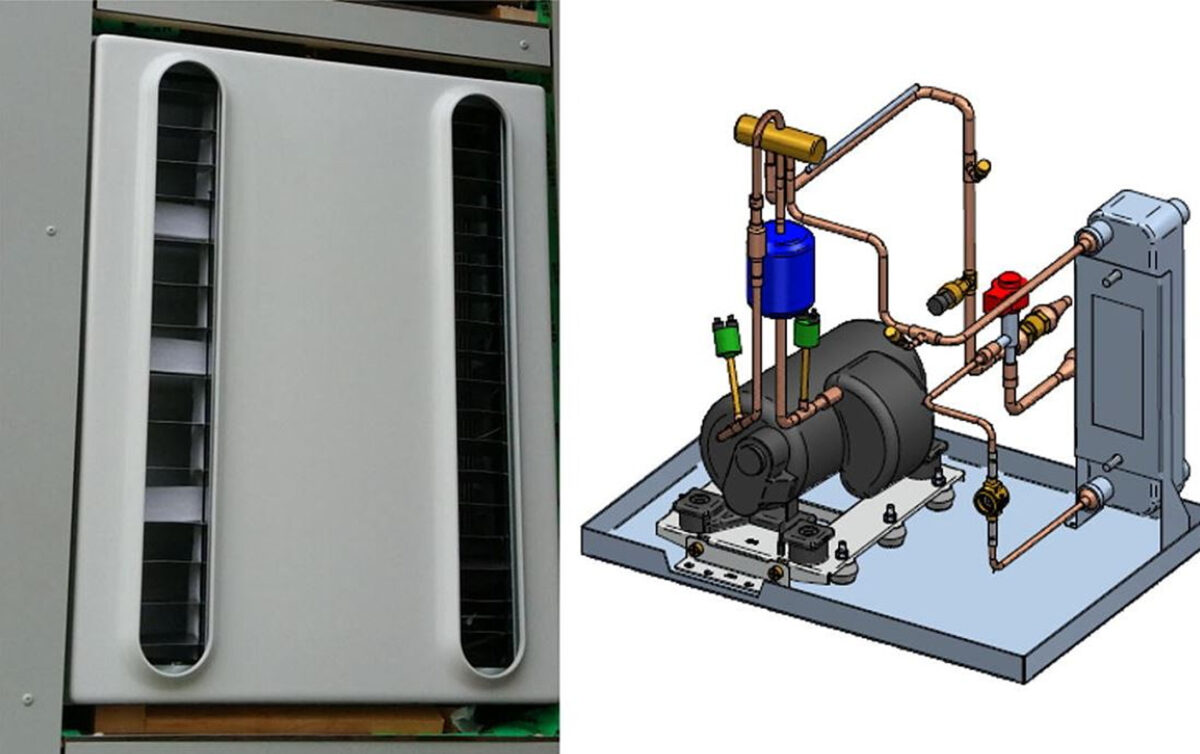

A group of researchers at the University of Innsbruck in Austria has designed a façade-integrated split-type heat pump (HP) for domestic hot water (DHW) production that is reportedly minimally invasive, compact, modular and silent.

The scientists explained that split-type façade-integrated HPs can be a viable alternative to gas boilers in renovated buildings when installation space is limited. “Due to the possibility of performing off-site work, prefabricated modular façades not only have a better performance from a building physics perspective but also ensure considerably lower construction time,” they added.

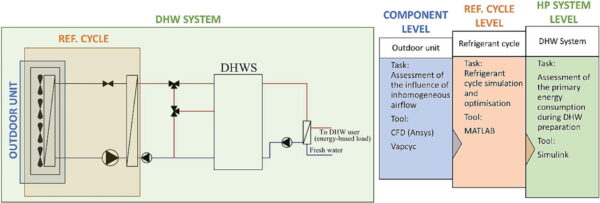

The research team said it designed the system through a holistic approach consisting of simulation and laboratory work assessing components, refrigerant cycles and system configuration. Their analysis considered the fluid dynamics and the performance of the outdoor unit, as well as its sound emissions and the dynamic interaction with the DHW user.

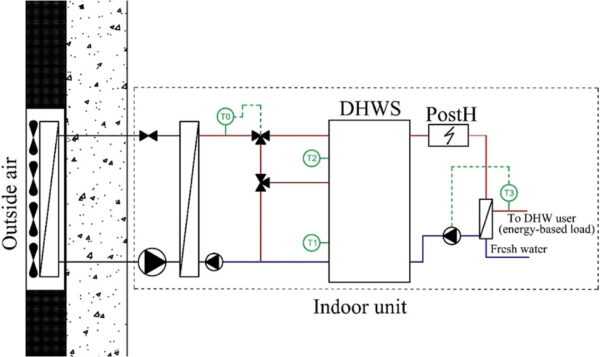

The system has a nominal heating capacity of 15 kW and uses propane (R290) as the refrigerant. It consists of one outdoor unit and one indoor unit with a domestic hot water storage tank with a capacity of 200 L. The system also includes a compressor, a condenser, and split ducts.

“The choice of a square pressureless tank was adopted to improve the compactness of the indoor unit and allow for some flexibility in its design,” the academics stressed. “With the current system configuration, it was possible to reach a minimum air temperature in the cold room of 10 C. For this reason, measurements at 10, 15 and 20 C cold air temperature were executed, while the ambient room temperature was kept constant at 20 C.”

The system also utilizes a magnetic 2-way valve for water withdrawal, three Pt100 temperature sensors to measure the temperature in the water tank, and four axial fans featuring low power consumption and sound emissions.

Image: University of Innsbruck, Applied Thermal Engineering, Creative Commons License CC BY 4.0

The researchers conducted a series of simulations and tests using MATLAB and Simulink software. The analysis showed that the system can meet the DHW demand of a small household already at −7 C outdoor air temperature with a temperature setpoint of 45 C. They also found that the ideal capacity of the tank is between 90 L and 110 L.

Popular content

“In cases where the compactness of the HP is the highest priority, a 90-litre storage tank could be chosen, even though some post-heating is required at lower outside air temperatures,” they specified. “On the other hand, in order to increase flexibility and to be less dependent on user behavior, a larger storage volume (e.g. 120 L) is the optimal choice.”

The scientists also found that the system has an airflow pattern in the evaporator that is close to a fully homogeneous one. Furthermore, they ascertained that it can supply the required hot water at an outdoor air temperature range of 10 C to 20 C, with an obtained system COP of 2.82 and 3.11, respectively. “The developed functional model was able to supply the comfort conditions at all tested outdoor temperatures,” they added.

They described the prototype in the paper “Simulation-assisted design of a silent façade-integrated R290 mini-split heat pump,” published in Applied Thermal Engineering. “The proposed façade integrated R290 mini-split HP is going to be installed in a demonstration project of a renovation of multi-family buildings in Vienna where it will be compared to centralized and semi-centralized HP concepts based on simulations and monitoring data,” they concluded.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

2 comments

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.