An international team of researchers announced an important achievement on the path to commercializing perovskite solar cells. Perovskite, a semiconducting material, is the focus of research around the globe due to its potential to convert more solar power to electricity than the commonly used silicon, and at lower cost.

There are drawbacks, however, in the production of perovskite solar. One of them is that the coating process must take place inside a chamber filled with non-reactive gas because otherwise the perovskites react with oxygen, thus decreasing performance.

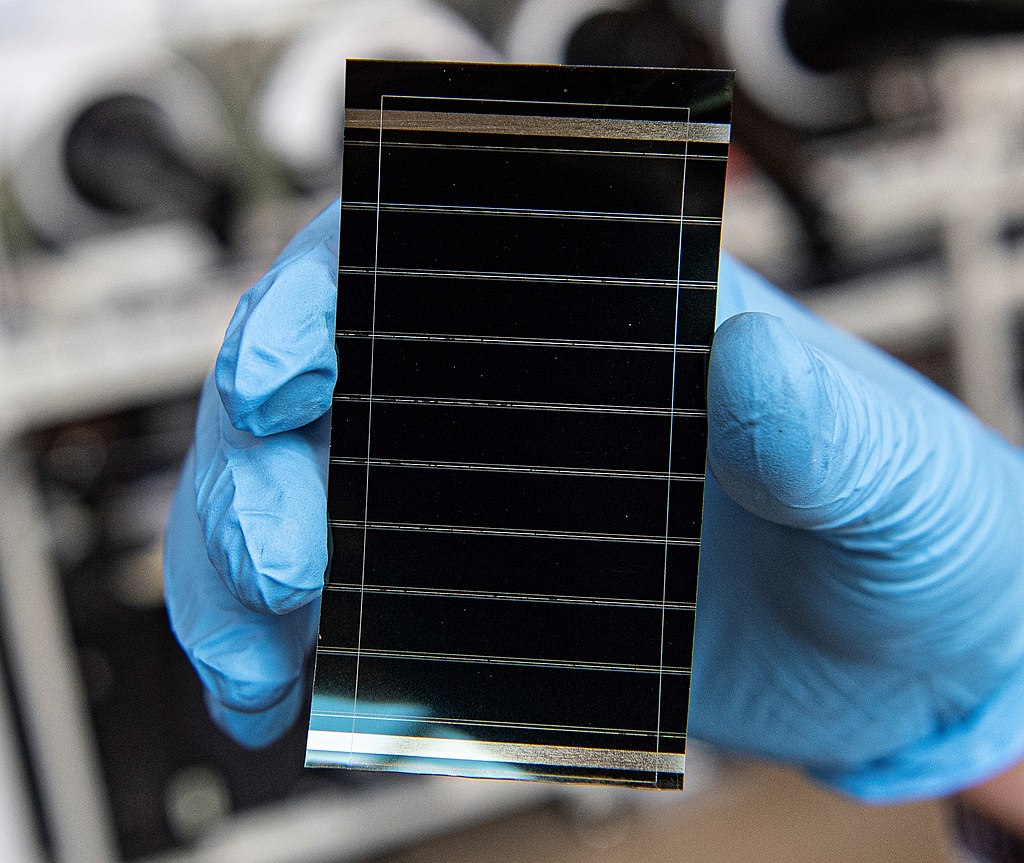

A new paper published in the journal Nature Energy describes the work conducted by Jixian Xu and his team at the National Synchrotron Radiation Laboratory, University of Science and Technology of China. The team found that adding dimethylammonium formate (DMAFo) to the perovskite solution before coating could prevent the materials from oxidizing. This discovery enables coating to take in ambient air instead of having to be inside a box.

Michael McGehee, a professor in the Department of Chemical and Biological Engineering and fellow with Colorado University Boulder’s Renewable & Sustainable Energy Institute, interpreted the results and helped with writing the paper. He told pv magazine that this was the first time DMAFo had been used in perovskite research and said it’s helpful because it is a reducing agent that prevents iodide from oxidizing. As he described it, the DMAFo was added into the perovskite precursor solution. “It protects the iodide in that solution, making it possible to make the cells in air and greatly extending the shelf life of the precursor solution,” McGehee said.

air. Time evolution of GIWAXS intensity along qz direction for the control (as cast perovskite wet film without DMAFo) (a) and the DMAFo sample (with DMAFo stabilizer). b shows the 2H, 4H/6H and 3C phases are labelled in the GIWAXS images.

McGehee acknowledged that coating inside a box is acceptable during the research phase, “but when you start coating large pieces of glass, it gets harder and harder to do this in a nitrogen filled box,” he said.

The results show that DMAFo perovskite cells can achieve an efficiency of nearly 25% on their own, comparable to the current efficiency record for perovskite cells of 26%.

The additive also improved the cells’ stability, which McGehee noted is important for the transition to clean energy.

An issue with perovskite solar compared to silicon is that they can degrade much faster. The study showed that the perovskite cell made with DMAFo retained 90% of its efficiency after being exposed to LED light that mimicked sunlight for 700 hours. In contrast, cells made in the air without DMAFo degraded quickly after only 300 hours.

McGehee noted that longer tests are needed because there are 8,000 hours in one year. “It’s too early to say that they are as stable as silicon panels, but we’re on a good trajectory toward that,” he said.

The next step for the team is to develop tandem cells with a real-world efficiency of over 30% that are as equally stable as silicon panels over a 25-year period.

After a decade of research in perovskites, engineers have built perovskite cells that are as efficient as silicon cells, which were invented 70 years ago, McGehee said. “We are taking perovskites to the finish line. If tandems work out well, they certainly have the potential to dominate the market and become the next generation of solar cells,” he said.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.