Researchers at Japan’s University of Miyazaki used a new non-destructive, Doppler laser-based method to investigate the effects of vibrations on solar cells embedded in a vehicle-integrated PV (VIPV) module, independently of the car roof and the module components. The study also explored the potential to design resonance-resistant vehicle VIPV modules.

“To my knowledge, no one has previously considered that the solar cells within the module can vibrate and resonate independently of the module structure. This paper is the first to provide measurement evidence indicating that solar cells can resonate inside the module at their natural resonance frequency,” corresponding author Kenji Araki told pv magazine.

The team reported that, unlike static installations in buildings that experience vibration frequencies ranging from 0.1 to 1 Hz, the vibration frequencies of PV systems in motion are in the range 1,000 Hz for trucks and 2,000 Hz for passenger cars.

In this range, the soft resins of the ethylene vinyl acetate (EVA) molecular chain movement do not dampen the vibration, according to the scientists. Despite the low damping factor of the EVA, the vibration tests did not reveal cell cracking.

“In our measurements and investigations, we found that resonant vibrations did not cause catastrophic stress that would induce cell fractures. However, recent studies on micro-electromechanical systems (MEMS) devices suggest that crystalline silicon may exhibit fatigue degradation under cyclic stress,” said Araki, referring to studies about silicon and polysilicon material fatigue in piezoelectric MEMS sensors and actuators.

“This implies that even if the stress level is below what causes cracks in solar cells, we need to be cautious, as increased dislocation density from cyclic stress could lead to rapid performance degradation in moving PV applications,” he stated.

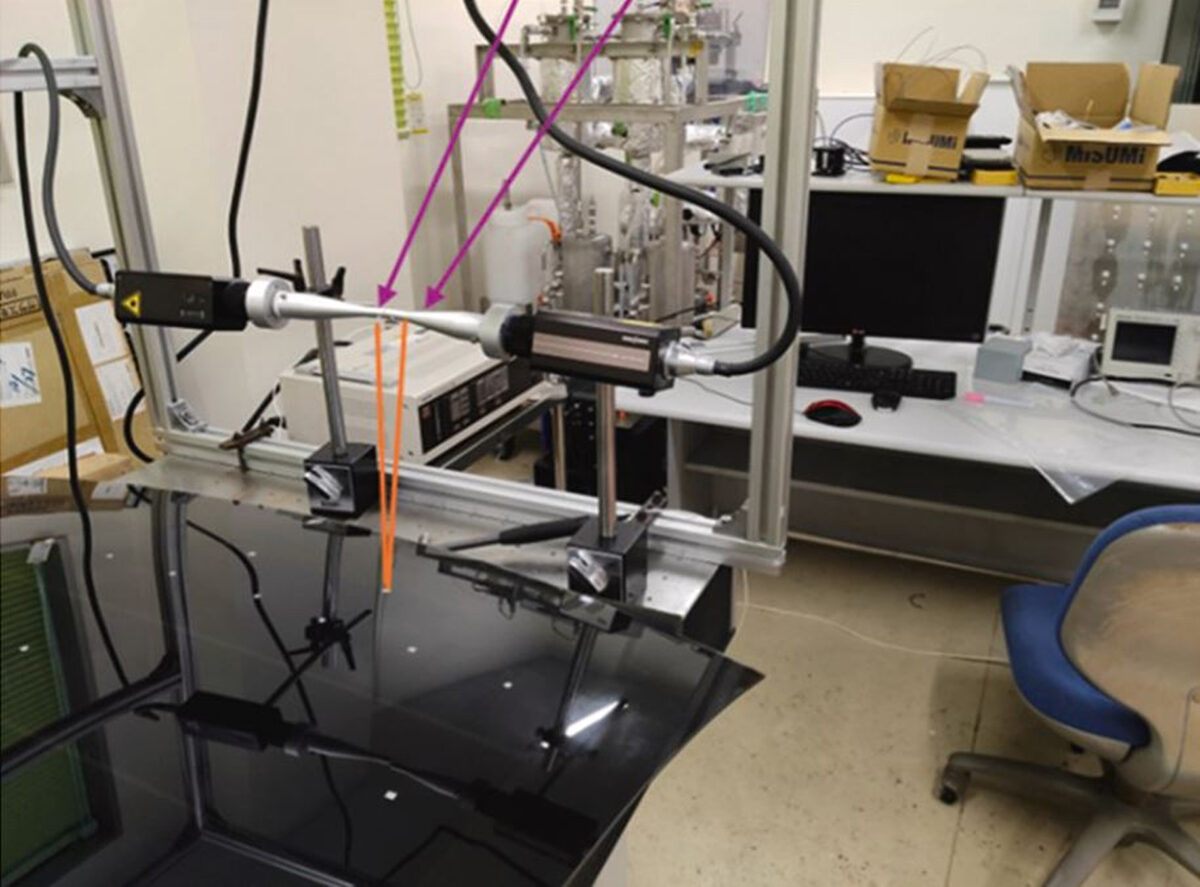

The non-destructive method used to measure the vibrations was based on a laser Doppler vibrometer (LDV). The use of a non-contact measurement approach was “essential” to avoid adding the weight of the sensor head to lightweight objects, such as solar cells, the scientists explained.

They also used silver stickers and micro-mirrors on the cover glass to avoid the bulky heads of the laser units interfering with each other, enabling separate vibration measurements of the glass and cells.

The laser Doppler technique was able to detect independent vibrational motion of a solar cell, also that the glass/EVA lamination resonates independently, and that the resonance frequency is close to the natural resonant frequency of the car roof. The measurements confirmed that the car roof vibrates at up to 2,000 Hz, as defined in the vibration test conditions in IEC 17650–3:2023.

In light of the results, the researchers noted that eliminating the source of vibration is not practical, but design modifications could increase the natural resonance frequency above 2,000 Hz by increasing the number of tab ribbons, for example.

The research team is now investigating the impact of cyclic stress on flexible PV modules, including how the modules handle stress during rolling and transportation, as well as the interaction between vibration stress and the local deformation of curved solar cells, according to Araki.

“Additionally, we are developing a non-contact inspection method to detect wrinkles or other local curvatures in solar cells, which are commonly seen in curved modules,” said Araki.

The work is documented in “Direct detection of vibration and resonance of the solar cells in vehicle-integrated photovoltaic modules,” published in Solar Energy Materials and Solar Cells.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.