A research team from the University of New South Wales (UNSW) and Sydney-based solar technology company SunDrive investigated the impact of annealing plated copper (Cu) contacts in heterojunction (HJT) solar cells and found that this process is unlikely to cause low-level fractures.

“We assessed the thermomechanical stress induced by annealing the Cu plated contacts on the pyramidal surface of HJT solar cells,” the research's lead author, Pei-Chieh Hsiao, told pv magazine. “The finite element analysis revealed that the Cu contact width is the most critical factor determining the silicon stress, rather than the area or volume of plated Cu. This means the inherent narrow Cu fingers are advantageous in both reduced optical shading as well as lower thermal stress.”

The scientists also evaluated the influence of the relative location of the Cu contact edge to the pyramid apex and size. “Importantly, high stress in silicon is induced locally at the Cu plated contact edge, which is experimentally confirmed with the relative stress measured by Raman spectroscopy. It is evident from the Weibull diagram obtained from four-point flexural tests that annealed Cu contacts introduced surface-limiting flaws. However, a very low probability of fracture of silicon is estimated for the typical annealing process at 200 C.”

The tests were conducted on M12 half-cut n-type HJT cells having a size of 210 mm x 105 mm and a thickness of 120 μm. The devices were coated with indium tin oxide (ITO) and exposed to Cu plating through a proprietary process developed by SunDrive using an acid-based copper electroplating solution. They were then rinsed in deionized water for 2 minutes and air-dried with a fan-forced infrared dryer.

In a further step, the research team placed the cells on a flat aluminum (Al) heating stage at a constant temperature of 200 C. Raman spectroscopy was used to identify potential regions of stress induced by annealing on the textured ITO/silicon surfaces next to the busbar lines and fingers.

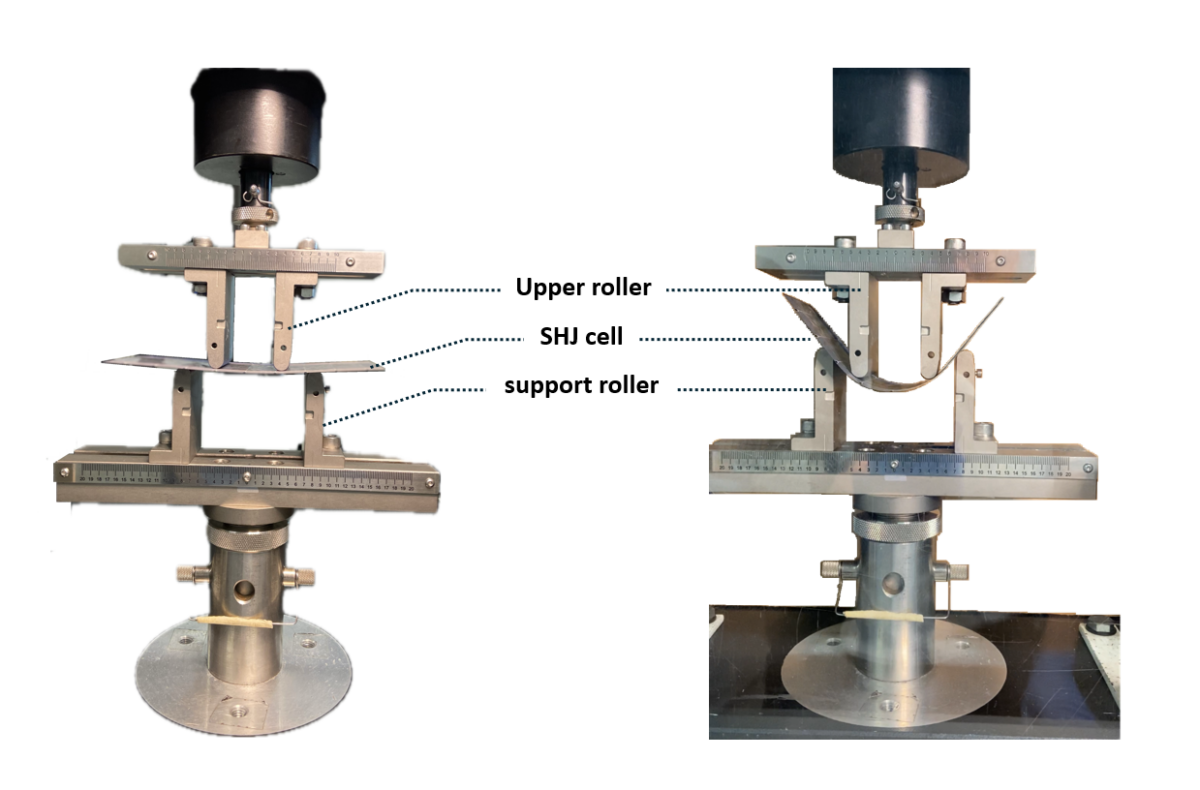

Furthermore, the group conducted a four-point flexural (4PF) test, which is a standard mechanical test to determine a material's bending strength and stress-strain behavior, to measure the mechanical stress induced by the Cu contacts.

The analysis identified the contact width of plated Cu as the main factor inducing stress in silicon. “The Cu volume or the contact area are not relevant in this regard,” said Hsiao. “Silicon stress increased with Cu width and stabilized when the contact width was greater than 50 μm. The Cu contact edge may be positioned at different distances from the pyramid apices.”

The scientists also warned that exceeding the 200 C threshold during annealing may increase the risk of low fractures, noting that spatial temperature inhomogeneity of around 20 C across the cell was found when using both conductive and radiative heating for cell annealing at 400 C.

Their findings are available in the paper “Investigation and Simulation of Thermomechanical Stress Induced by Plated Cu Contacts on Si Heterojunction Solar Cells,” published in Progress in Photovoltaics.

Another research group led by UNSW recently measured the impact of sodium-induced degradation in heterojunction solar cells under accelerated damp-heat testing. They considered three different types of sodium salts and identified the degradation mechanisms attributed to each contaminant.

Other UNSW researchers in 2023 investigated failure modes in HJT solar modules with glass-backsheet configurations. They identified four failure modes caused by damp heat in heterojunction solar panels with a glass-back sheet configuration.

More recently, a group of researchers from French research center Institut Photovoltaïque d'Ile-de-France (IPVF) and EDF R&D, a unit of French energy giant EDF, conducted a series of tests to assess the reliability of HJT solar panels in a damp heat environment and identified sodium ions as the main degradation factor.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.