Researchers at Chonnam National University in South Korea deposited a germanium oxide layer using vapor processing at the rear contact interface of thin film tin monsulfide (SnS) solar cells to improve solar cell power conversion efficiency to 4.81%, up from 3.7% for the standard cell.

Though known as a cheap, abundant material with promising characteristics for use in solar cells, tin monosulfide (SnS) has proved a challenging material to work with, and researchers have so far struggled to achieve conversion efficiencies better than 5% with this material, and interest from the research community has lagged behind that of kesterite, or copper-zinc-tin, solar cells.

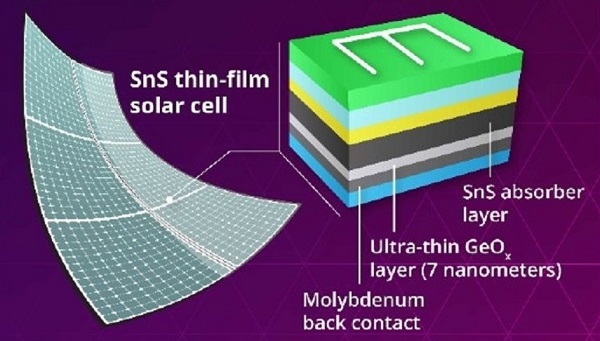

The team fabricated the cell by depositing a 7 nanometer germanium oxide (GeOx) layer between the molybdenum back contact and the SnS absorber layer in a process that entailed interface engineering, defect passivation, and contact optimization “to translate material advances into stable, high-performance devices suitable for scalable photovoltaic applications,” according to corresponding author of the research Jaeyeong Heo.

“Our team in South Korea has been actively working on thin-film solar cells for many years, with a strong focus on earth-abundant and environmentally benign absorber materials such as kesterite, SnS, and related chalcogenides,” Heo told pv magazine.

The group selected SnS not only due to its earth-abundant, non-toxic features but also because it has a “near-ideal bandgap” of ~1.3 eV, and “strong optical absorption” of ~104 cm-1, according to Heo who also highlighted that SnS thin-film devices have “historically underperformed due to interface losses and defect-related recombination rather than intrinsic material limitations.”

The experimental device stack was as follows: soda lime glass, molybdenum contact layer, GeOx, SnS absorber, cadmium sulfide (CdS) buffer layer, intrinsic zinc oxide (i-ZnO), aluminum-doped Zinc oxide (AZO) window layer, aluminum metal contact.

In testing, the researchers noted that the vapor transport deposition process provided a means to passivate deep-level defects and suppress sodium diffusion at the substrate, enabling “larger, more uniform grains,” enhanced charge transport, and a reduction in electrical losses to achieve the “substantial” boost in power conversion efficiency, “delivering a PCE of 4.81%, one of the highest values reported for SnS-based” thin film solar cells, noted the researchers.

As detailed in the study, “Rear-interface passivation using a controlled germanium oxide (GeOₓ) interlayer,” published in Small, subsequent device stability tests were performed three months after fabrication. A device without encapsulation retained more than 96% of its initial efficiency, demonstrating “excellent long-term stability.”

In earlier research other performance bottlenecks were addressed through targeted interface and surface engineering. Last year, for example, the group reported in Journal of Materials Chemistry A a sulfur “pre-baking” approach, which clarified the “critical role of sulfur stoichiometry control” in improving film quality and photovoltaic performance.

“Looking ahead, our team plans to integrate these individual advances into unified device architectures by combining optimized source engineering, surface treatments, and contact passivation in a single platform,” stated Heo. Research topics include developing physics-based models, deposition technology, and exploring SnS-based tandem, quantum dots-based or hybrid device concepts.

“Ultimately, our goal is to establish SnS as a competitive, earth-abundant thin-film technology that offers both high efficiency and long-term stability, making it suitable for real-world deployment,” said Heo.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.