Medium-voltage power plants are often more flexible, cost-effective, and easier to integrate into local grids than high-voltage plants, making them ideal for distributed solar projects or regions without ready access to high-voltage transmission infrastructure. High-voltage plants are more suited to utility-scale generation for long-distance transmission, but are more prone to transmission losses and require significant planning and investment upfront. Moreover, high-voltage facilities require stricter safety measures, more complex protection systems, and specialized personnel.

With these advantages in mind, a team of researchers at the Germany's Fraunhofer ISE is currently planning the construction of what it describes as the world's first medium-voltage photovoltaic plants, in an effort to reduce copper and aluminum consumption.

“The move to medium voltage is a key lever for reducing the demand for copper and aluminum in large-scale photovoltaic power plants and thus for the economic viability of the projects,” said Fraunhofer ISE researcher Felix Kulenkampff. “On the one hand, doubling the voltage leads to savings in conductor cross-section of around 75%. Thinner cables are easier to lay and also reduce installation costs. In addition, the connected load of transformers and substations can be doubled without changing their size. In large power plants, their number can be halved, leading to further savings in material, investment, and installation costs.”

The team is planning to build two 135 kW pilot plants in the German region in Baden-Württemberg and Rhineland-Palatinate.

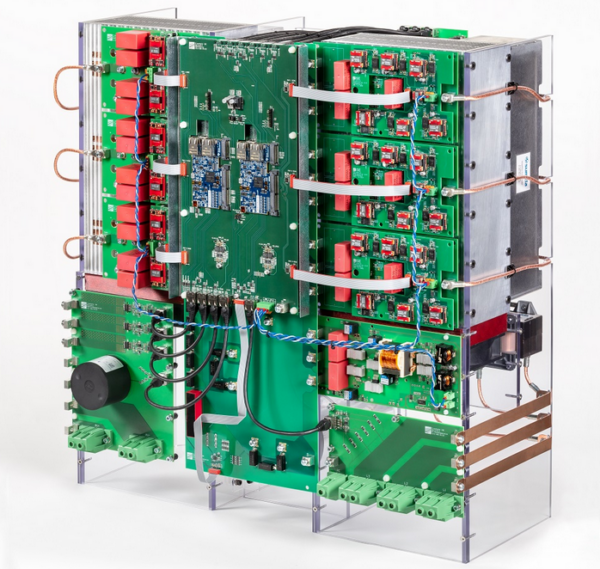

“They will be operated at 3 kV on the DC side and 1.2 kV on the AC side,” the Fraunhofer ISE said in a statement. “The medium-voltage PV inverter used, based on high-blocking silicon carbide semiconductors, was already developed by Fraunhofer ISE in the MS-Leikra project and is being adapted for use in the field.”

The project tests two string configurations: standard 1500 V solar modules with center-point grounding and 3 kV strings using prototype modules for higher voltages.

The researchers believe that building cost-competitive and voltage-resistant components is feasible and for this purpose they are working with partners such as Pfalzwerke AG, the FEAG Group, Stäubli Electrical Connectors AG, Weidmüller Interface GmbH & Co. KG, Mersen Deutschland Eggolsheim GmbH, Prysmian Kabel und Systeme GmbH, Sumida Components & Modules GmbH, Hanwha Q Cells GmbH, Zimmermann PV-Steel Group GmbH & Co. KG, Infineon Technologies AG, Fluke Deutschland GmbH, and BES new energy GmbH.

The German Federal Ministry for Economic Affairs and Energy is financing the research project under the umbrella of the 8th Energy Research Program “Innovations for the Energy Transition.”

Image: Fraunhofer ISE

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.