Researchers at Ritsumeikan University in Japan have tested a new type of polyethylene terephthalate (PET) front sheet and related encapsulation methods to improve durability of copper indium gallium diselenide (CIGSe) solar mini-modules. They found that such devices exposed to damp heat testing for 3,600 h retained approximately 97 % of their initial efficiency.

The research is part of an ongoing effort towards robust and lightweight glass-free thin film PV modules for a range of applications. “This work is on the encapsulation of the CIGSe device with film cover with high barrier layers for future light weight and flexible devices,” corresponding author of the research Minemoto Takashi told pv magazine.

The researchers chose to study polyethylene terephthalate (PET) film as it is favored for flexible solar modules due to chemical resistance, for example, but research on such materials has been limited.

In the study, the researchers used a high-barrier flexible PET front sheet with a WVTR of 10-3g/m2/day and a black polymer tape seal to further enhance the encapsulation. Additionally, they applied a passivating bias voltage, which played a “crucial role” in stabilizing the performance of the CIGSe mini-modules throughout the damp heat test.

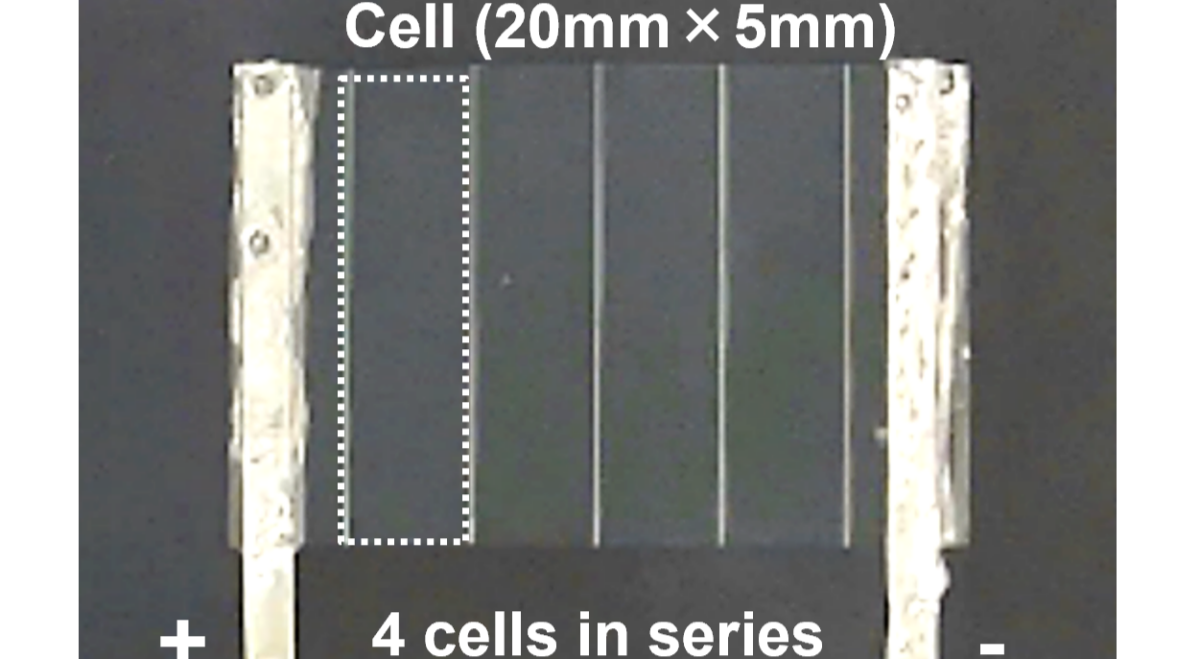

In the experiments, two 6 cm2 CIGSe mini-modules with initial efficiencies of 18.33 % and 18.34 % were provided by the National Institute of Advanced Industrial Science and Technology (AIST). One was continuously biased near its voltage at the maximum power point (Vmpp) and the other was left under unbiased conditions.

The encapsulation structure was as follows: a flexible PET front sheet/a thermoplastic polyolefin (TPO) encapsulant/CIGSe mini-module/TPO, PET-Al back sheet. Both the front sheet and backsheet were supplied by Japan-based Dai Nippon Printing.

“This combination of materials ensures the flexibility and minimizes damage during the lamination process, which involves vacuum lamination and pressing process at 150 C for 6 min at 100 kPa,” said the researchers.

The damp heat (DH) tests showed that “both biased and unbiased mini-modules demonstrated good stability throughout the first 1,872 h of the DH test, maintaining high performance with efficiency retention of 100% and 97%, respectively,” said the researchers, noting that the biased PET/TPO combination performed even better, showing “remarkable stability” after more than 3000 h, maintaining about 97% of their initial efficiencies.

“This high stability indicates the effectiveness of the encapsulation structure, particularly the suitability of the top front sheet during the DH test. Therefore, the proposed encapsulation structure is potentially more stable if it is coupled with a higher WVTR front sheet,” said the researchers.

“The flexible high-barrier front sheet enables a glass-free encapsulation and flexible modules, overcoming limitations of traditional glass encapsulation,” concluded the team. They also stressed that “maintaining a stable and well-regulated bias voltage,” could further enhance long-term durability and gain higher performance retention.

Further research into scaling up the use of materials evaluated in the study was recommended, as well as field testing and a systematic investigation on the impacts of electrical bias.

The work is detailed in “Cu(In,Ga)Se2 mini-modules demonstrate damp heat stability exceeding 3000 h via advanced encapsulation and bias management,” published in Solar Energy. The research participants were from Dai Nippon Printing Co. And National Institute of Advanced Industrial Science and Technology (AIST).

Looking ahead, the research group is working on technology required to enable building integrated PV (BIPV) applications. “Our next target is perovskite-CIGS tandem device with a light weight and flexibility for expanded PV applications, such as lightweight roof, building facade, and mobility,” said Takashi.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.