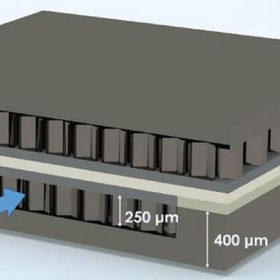

Monolithic fuel cell with power density of 5.6kW/L

An international research group has developed a solid oxide fuel cell that may be used in vehicles. The monolith device has an active cell area of around 18 cm2 and was built through common manufacturing processes. It was found to achieve a high power density of 5.6 kW/L, which the scientists said is comparable with that of the best performing fuel cells based on ceramic anodes.

The Hydrogen Stream: Hydrogen-powered trains for the German network

Elsewhere, the Danish government announced a plan to deploy up to 6 GW of electrolyzer capacity by 2030 and Germany and Norway agreed to conduct a feasibility study on large-scale hydrogen transport, including via pipeline.

Investment cycle means race is on to incentivize green hydrogen

A report published by Irena hints the world’s politicians will have to get to work immediately to avoid another generation of fossil fuel-fired hydrogen, ammonia, and methanol plants being set up to run into the second half of the century.

Spanish consortium wants to produce green hydrogen with sewage

The Zeppelin project is expected to generate more than 135,000 tons of green hydrogen from 99 million tons of waste and 50 million tons of municipal wastewater.

Australian electrolyzer invention enables green hydrogen under US$1.5/kg by ‘mid 2020s’

“We’re not talking about incremental improvement, this is a really giant leap,” Hysata CEO Paul Barrett told pv magazine Australia. Hysata is commercializing a breakthrough made at the University of Wollongong which effectively, Barrett says, invented a “brand new category of electrolyzer,” vastly improving efficiency.

The Hydrogen Stream: Universal Hydrogen builds manufacturing facility in the United States

Elsewhere, Scatec and partners have signed a memorandum of understanding to develop a large scale green ammonia facility in Egypt. Hydrogen developments were also announced in India and the United Kingdom.

Paving the way for green hydrogen certification

The International Renewable Energy Agency has outlined a series of technical considerations for green hydrogen tracking systems. According to the document, a degree of flexibility should be taken into account in the short term to ensure that the nascent green hydrogen market can develop.

The Hydrogen Stream: Metal foam for low-cost green hydrogen generation

Researchers from Saudi Arabia’s King Abdullah University of Science and Technology have presented the results of a low-cost method of generating carbon-free hydrogen. In other news, Norwegian fuel cell producer Nel ASA said it was ready to increase its electrolyzer production capacity to meet the European Union’s raised ambitions for renewable hydrogen, while oil giant Petronas Eneos announced plans to set up a hydrogen production plant in Indonesia.

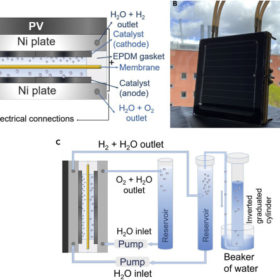

Thermally integrated PV-electrolyzer with 9.1% solar-to-hydrogen efficiency

A Swedish research group has developed a device combining CIGS thin-film solar modules and an alkaline electrolyzer based on a trimetallic cathodic catalyst made of nickel, molybdenum, and vanadium (NiMoV) and an anode made of nickel oxide (NiO). The electrolyzer achieved an average solar-to-hydrogen (STH) efficiency of 8.5% for stable operations during 100 hours.

The EU plan to drastically ramp renewables to replace Russian gas

The European Commission yesterday announced its intent to remove demand for two-thirds of its Russian gas supply in less than nine months and hugely accelerating the rate of solar deployment is a central part of its radically raised clean energy ambition.