Scientists assess lifetime for perovskite PV to become competitive on rooftops

Researchers say that lightweight, high-performance perovskite solar modules could soon become competitive with crystalline PV modules in the residential segment, as such products will likely have lower manufacturing and balance-of-system costs in the future.

Falling costs, 15 GW of US solar module production, TOPCon trends

A recent Wood Mackenzie report looks at trends and challenges in the burgeoning US solar market, including manufacturing stimulated by the US Inflation Reduction Act.

Australian scientists source silicon from solar waste to build better batteries

Researchers from Victoria’s Deakin University say they have successfully tested a new process that can safely and effectively extract silicon from end-of-life solar panels, and then convert it into nano materials worth more than $45,000 (USD 31,500) per kilogram, in order to build better batteries.

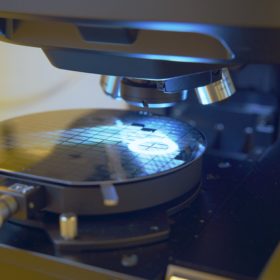

TÜV Rheinland opens solar module testing lab in China

Germany’s TÜV Rheinland said it will invest €22 million in the 5,000 m2 facility for testing photovoltaic modules as part of a massive lab.

Eggplants grow 50% more under solar panels

French specialist Sun’Agri unveiled the agronomic results on a crop of eggplant grown in a greenhouse commissioned in the Lot-et-Garonne in September, 2020.

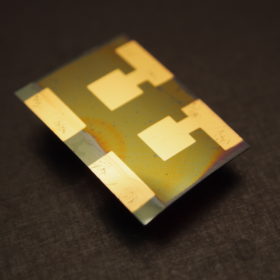

US startup begins producing 40%-efficient thermophotovoltaic cells

Antora Energy says its new 2 MW factory will make thermophotovoltaic cells for thermal storage applications. The cells are based on III-V semiconductors and reportedly have a heat-to-electricity conversion efficiency of more than 40%.

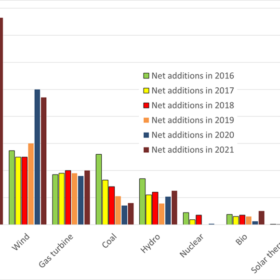

The fastest energy change in history

Solar and wind are being installed at a rate that is three times faster than all other new electricity sources combined. This offers compelling market-based evidence that PV and wind are now the most competitive and practical methods for deploying new generating capacity.

New way to calculate LCoE of perovskite solar

Italian researchers have analyzed different ways to assess the levelized cost of energy (LCoE) of perovskite solar cells and modules. They said a common approach should soon be defined to increase the market maturity of the tech.

Only5mins! – The steeplechase of perovskite solar

The potential of perovskite solar cells and modules is still held back by issues such as stability and efficiency losses when scaling up from cell to module. But Annalisa Bruno, a scientist at Singapore’s Nanyang Technological University, says most of these challenges could be overcome in the near future, with this technology extending from building-integrated PV to conventional solar projects.

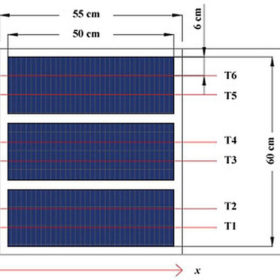

Passive solar module cooling tech based on paraffin wax

Egyptian researchers have used paraffin wax as a phase-change material (PCM) to reduce the operating temperatures of PV modules. They have found that the material improves power yield by more than 15%, compared to a reference module without cooling.