GCL-Poly’s polysilicon sales fall 43% in Q1

The Chinese energy group’s external sales of polysilicon fell about 43.4% year on year to 1,896 metric tons (MT) in the January-March period.

U.S.-Turkish research team uses data science to predict PET back-sheets degradation in solar modules

The scientists have used engineering epidemiology and statistical-data analytics to predict how polyethylene terephthalate films in solar panels deteriorate under multi-factor accelerated weathering exposures.

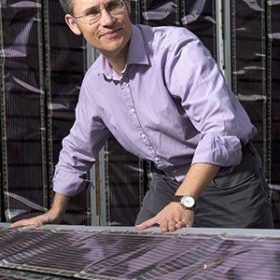

Uni Newcastle team tests “printed solar” panels in Australian first

Just days after Tesla announced it was taking orders – and down-payments – for its much-hyped and quite good looking solar roof, an Australian made printed solar innovation that could rival Elon Musk’s power generating tiles has moved one major step closer to commercialisation.

Atomic scale design could pave the way to more persistent solar cells, study says

Researchers from ICL claim to have discovered the cause for the rapid decrease in performance of perovskites. Adding iodide ions may help improve the stability of solar cells.

Trina hits 24.13% total-area efficiency for IBC mono cell

The new record is just 0.24% below the Chinese company’s small-area laboratory cell record and has been achieved on an industrial, large area cell.

University of Twente publishes research on back reflector materials

Researchers at the Netherlands’ University of Twente have developed a material comprising thin, diamond-like photonic nanostructures which reflect a surprisingly wide range of colours of light, from all angles. This could make the material ideally suited for use as a back reflector for PV modules.

Natcore achieves 20.7% efficiency on silver-free back contact cell

The latest efficiency milestone for Natcore’s Foil Cell is verified by the NanoPower Research Lab at Rochester Institute for Technology. The result was achieved on the Natcore Foil Cell, which utilizes a lasering process and novel metallization strategy, eliminating the need for costly silver.

KIT researchers detect nanostripes on perovskites

KIT scientists have researched the underlying physical mechanisms of perovskites to understand the reason for their high efficiency potential. For the first time proof for nanostructures in the perovskite layers has been provided.

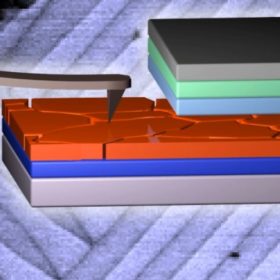

Masdar & MIT develop method for high efficiency semiconductor materials

Researchers from the Abu Dhabi based Masdar Institute and the renowned Massachusetts Institute of Technology have jointly published the development of a fabrication method, which they say could make high efficiency semiconductor materials such as gallium-arsenide, indium phosphide and others more competitive with crystalline silicon.

Swiss researchers develop new process for back contact cell production

A team of researchers from École polytechnique fédérale de Lausanne (EPFL) and the Swiss center for Electronics and Microtechnology (CSEM) has developed a new process for fabricating cells with all electrical contacts at the rear. According to EPFL, the process has already achieved lab efficiencies in excess of 23%.