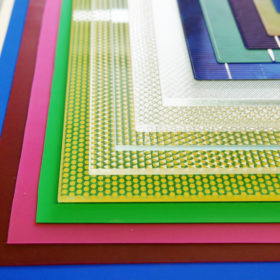

Fraunhofer ISE, Schmid develop production line concept for custom design modules

German research institute, the Fraunhofer Institute for Solar Energy Systems (ISE) and equipment supplier, Schmid have jointly developed a production line for customizable modules for building-integrated projects. According to Fraunhofer ISE, the concepts developed by joint study could reduce the production cost for BIPV modules as much as 35%.

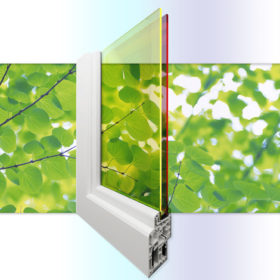

Berkeley Lab researchers develop perovskite ‘smart window’ material

Scientists from the renowned U.S. Berkeley Laboratory have discovered a perovskite material, which can be used in photovoltaic glass applications, and can be switched between transparent and non-transparent without diminishing its electronic properties.

Skanska, Saule Technologies to install BIPV perovskite modules on office buildings

The two companies have signed a license agreement. The first pilot projects with the semitransparent perovskite solar cells are planned for this year in Poland

U.S. researchers develop quantum dot solar glass

A team from the Los Alamos National Laboratory has developed a double pane solar glass, using quantum dot PV technology. The researchers say the glass could be integrated into buildings as a semi-transparent window, or added to existing solar panels to boost efficiency.

Solar Frontier to venture into BIPV — report

Japan’s Solar Frontier plans to start integrating its thin-film PV technologies into materials for walls and roofs, with sales expected to begin before the end of the decade, according to a recent report.

ENGIE teaming with Heliatek to install HeliaSol lightweight technology at French school

ENGIE‘s teams have responded to tender calls by the Charente-Maritime Department, and will offer to cover a 530 square meter roof of secondary school Pierre Mendès-France in la Rochelle using HeliaSol technology.

BIPV: Researchers develop solar glass blocks to power houses

Researchers at the UK’s Exeter University have created solar cell-embedded glass bricks, which in addition to generating electricity let in natural light and provide thermal insulation.

British university to drive £7m Indian BIPV solar project

Swansea University will lead a consortium of 12 British and Indian universities on a £7 million project to build five solar-powered buildings in remote Indian villages that will be fully self-sufficient.

Property developer unveils solar facade in Bern

Property developer Fambau has unveiled a new building in the Swiss capital which includes an installation of 130 Avancis thin-film modules integrated into the building’s southern façade. According to Avancis, the installation takes up 135 square meters, and will generate up to 12 MWh per year.

‘Solar sunglasses’ demonstrated by researchers at KIT

Scientists at Karlsruhe Institute of Technology (KIT) in Germany have developed a pair of sunglasses that generate electricity through semi-transparent organic solar cells applied to the lenses. The team aims to demonstrate the potential of organic solar to be integrated into electronic devices, buildings and other applications not possible with conventional PV technologies.