Building integrated photovoltaics (BIPV) has shown plenty of potential in recent years; however, several issues must still be addressed for the technology to see more serious growth. Chief among these are demands that architects and the building industry place on module design, where aesthetics and design choices are just as important as performance.

Looking to address this problem at the production side, Fraunhofer ISE and Schmid undertook a project investigating existing standards and design limitations for BIPV modules, as well as analyzing the market potential and requirements.

Based on the findings of the study, which was funded by the German Federal Ministry for Economic Affairs and Energy, the two organizations have developed two new production line concepts for flexible series production of BIPV modules.

Popular content

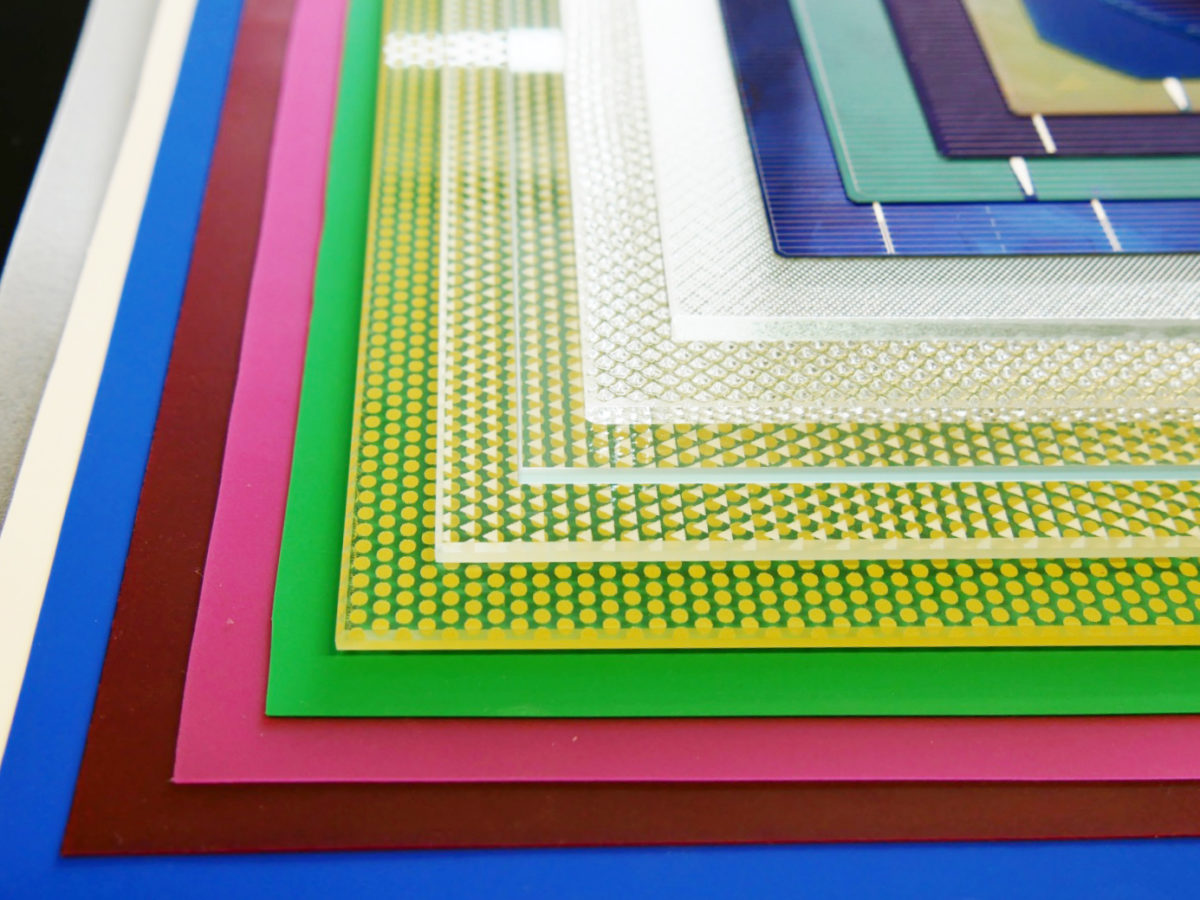

The production line concepts consider the need to quickly adapt to different module designs, and the modifications needed for integration into different buildings – such as module format, glass color/thickness, solar cell matrix and encapsulation material.

“Our results showed that the combination of series production and freedom of design do not compromise each other,” says Stefan Sellner, Project Head at Schmid. “We also demonstrated that we can reduce the costs by an average of 35 percent compared to conventional manufacturing processes of BIPV modules.”

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

3 comments

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.