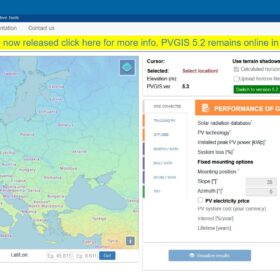

EU updates Photovoltaic Geographical Information System

The EU Joint Research Centre (JRC) has updated the core technologoy of the Photovoltaic Geographical Information System with the aim of reflecting the dominance of crystalline silicon solar technologies over thin-film counterparts in the global energy market.

How will PV’s intellectual-property scuffles shake out?

Lawyers are doing brisk business as tunnel oxide passivated contact (TOPCon) solar technology moves into the mainstream. A series of patent infringement cases have been launched in the United States and Europe and their impacts are reverberating through the marketplace. How likely is it that winners will emerge?

US, Canada ramp up solar glass plans

With PV module capacity ramping up, glass suppliers have been investing in new solar glass production capacity. As in India and China, new facilities are popping up in North America, with unique twists to ensure competitiveness, such as using recycled material.

Weekend Read: Thin prospects

The production of PV ingots and wafers remains the most highly concentrated of all the production stages in the silicon solar supply chain. Yet efforts to re-establish production in Europe and the United States are not for the faint-hearted.

Building bridges between East and West

Italian module manufacturer FuturaSun has big expansion plans in China, with the first phase of a 15 GW silicon cell fab due online in Huai’an in the first quarter of 2024, in addition to 1 GW of module production in Taizhou. Erik Eikelboom, technical adviser to FuturaSun, offers a closer look at the project.

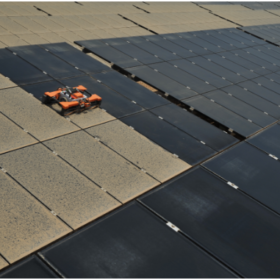

Impact of dust, heat, soiling on solar project performance

Scientists in Morocco recently conducted a year-long study on the impacts of soiling on PV modules in arid, dusty conditions. They found that soiling could contribute to daily performance losses of as much as 15%.

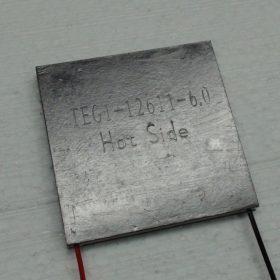

Upcycling silicon waste from end-of-life solar panels into thermoelectrics

Researchers in Singapore have developed a new technique in which polycrystalline silicon is pulverized into powder and pelletized into ingots. The process relies on spark plasma sintering to dope the silicon with germanium and phosphorus.

Shanghai Electric sounds death knell for CIGS manufacturing project backed by $197m of public money

With five public entities having committed RMB1.25 billion into a project to produce copper, indium, gallium, selenide solar modules five years ago, the joint venture has been abandoned at an estimated impairment cost of RMB1.42 billion.

The weekend read: BIPV no refuge

Deployment in the building integrated PV segment is accelerating, and so too are the number of solar products available to architects and developers. And while BIPV had long been the segment in which an array of thin-film technologies could shine, they are now in increasingly stiff competition with crystalline silicon rivals.

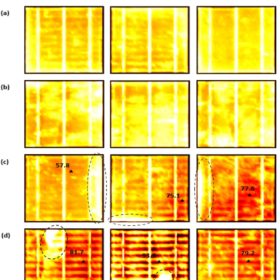

Damaging defects in silicon solar cells

Scientists in the UK investigated the relationship between two of the most worrisome defects that can affect solar cells in the field – cracking and hotspots. Their work analyzed solar cells with different levels of cracking under varying light conditions, finding that the most severely cracked cells were considerably more likely to run at high temperatures and form damaging hotspots.