US startup claims hydrogen output for $0.85/kg or less via new water vapor electrolyzer

Advanced Ionics has developed an electrolyzer that runs at temperatures below 650 C. It is reportedly able to produce hydrogen for $0.85/kg or less. CEO Chad Mason recently spoke with pv magazine to provide a closer look at the water vapor electrolysis tech.

Fluid gas market situation casts shadow over EU energy system models

With each of the 10-year network development plans produced by Europe’s electricity transmission system operators years in the making, the latest such publication may already be out of date as the bloc prepares to fast forward its energy security and climate change ambitions.

Investment cycle means race is on to incentivize green hydrogen

A report published by Irena hints the world’s politicians will have to get to work immediately to avoid another generation of fossil fuel-fired hydrogen, ammonia, and methanol plants being set up to run into the second half of the century.

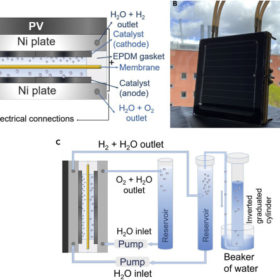

Thermally integrated PV-electrolyzer with 9.1% solar-to-hydrogen efficiency

A Swedish research group has developed a device combining CIGS thin-film solar modules and an alkaline electrolyzer based on a trimetallic cathodic catalyst made of nickel, molybdenum, and vanadium (NiMoV) and an anode made of nickel oxide (NiO). The electrolyzer achieved an average solar-to-hydrogen (STH) efficiency of 8.5% for stable operations during 100 hours.

Hydrogen under $3/kg may ensure affordable seasonal energy storage in the US

Researchers from the United States have investigated how fuel cells and electrolyzers may be able to operate under intermittent availability provided by both wind and solar and have found that an affordable hydrogen-based system for seasonal energy storage could be achieved at a hydrogen price lower than $3, produced from inexpensive renewable electricity at $0.02/kWh.

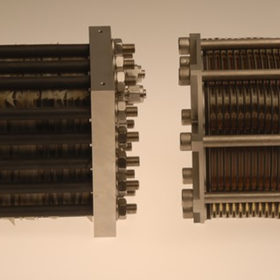

Water-based electrolyzer for green hydrogen production

Verdagy has secured a $25 million investment for its new electrolyzer technology, which provides hydrogen fuel for heavy industrial applications. The membrane-based technology uses large active area cells, high current densities, and broad operating ranges to deliver hydrogen at scale.

Large scale alkaline electrolyzers may be built at €444/kW in 2030

Researchers at Germany’s Fraunhofer ISE have estimated the costs for both alkaline (AEL) and proton exchange membrane (PEM) electrolyzers and have found that AEL systems have bigger margins for cost reduction. According to their calculations, the costs of a large scale AEL electrolyzer with a capacity of 100MW should drop from €663/kW in 2020 to €444 in 2030.

The Hydrogen Stream: Fortescue develops tech based on photocatalytic water splitting coupled with solar

Australia’s Fortescue Future Industries wants to develop a green hydrogen technology based on photocatalytic water splitting coupled with solar radiation. Elsewhere, Linde has signed a long-term agreement with German chemical company BASF for the supply of hydrogen and steam in France and Nel has received a contract for a containerized PEM electrolyzer and light-duty hydrogen fueling station package from an unnamed U.S. power utility.

The Hydrogen Stream: New fuel cell design to solve longstanding problem of overheating

Los Alamos National Laboratory researchers developed a new polymer fuel cell that is claimed to solve the long-known issue of overheating. Furthermore, Mexican cement producer Cemex invested in HiiROC, a UK-based hydrogen production startup, which developed a scalable technology that uses thermal plasma electrolysis to convert biomethane, flare gas, or natural gas into hydrogen at a reportedly lower cost than competing solutions.

The Hydrogen Stream: Novel fuel cell tech based on liquid-organic hydrogen carrier

Germany’s Schaeffler is developing a hydrogen fuel cell that runs on a liquid organic hydrogen carrier, and Australia’s H2X Global has formed a joint venture with Indian automotive components manufacturer Advik Hi-Tech to manufacture hydrogen fuel cells, generators and vehicles.