Single-junction III-V solar cell based on spalled GaAs substrate achieves 26.9% efficiency

NREL researchers used acoustically spalled gallium arsenide substrate that reportedly reduces electrical shunting, resulting in potentially lower manufacturing costs. The cell achieved an open-circuit voltage of 1.061 V, a short-circuit current density of 29.9 mA/cm2, and a fill factor of 84.9%.

Ultra-thin, radiation-resistant solar cells for new space applications

UK scientists have developed a solar cell based on a layer of gallium-arsenide just 80 nanometers thick, with similar performance to much thicker devices. It showed excellent resistance to damage from radiation exposure, making it ideal for high-radiation satellite/space applications.

Gallium arsenide nanowire solar cell with 7.7% efficiency

Norwegian scientists have developed a gallium arsenide (GaAs) nanowire solar cell that can be used as a top cell in a dual tandem cell with a bottom silicon cell. The device is claimed to be the most efficient single-junction GaAs nanowire solar cell grown on a silicon substrate so far.

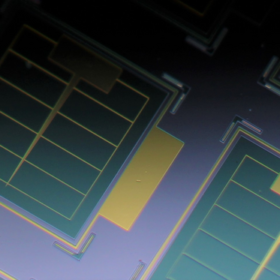

Four-terminal III-V solar cell with 32.57% efficiency

Scientists at the US National Renewable Energy Laboratory have simulated a III-V solar cell by stacking gallium arsenide films onto interdigitated back contact silicon solar cells with a glass interlayer. The scientists have already done some initial mini-module integration work, but significant size scaling will ultimately be needed to reach commercialization. The cell currently has an active area of 1 cm2.

IEA highlights solar’s dependence on Chinese copper processing

The sheer volume of new power lines which will be required to accommodate the rising tide of solar installations ensures copper has been included by the International Energy Agency on its list of minerals which must keep flowing if the energy transition is to stay on course. And it’s not production that’s the potential bottleneck.

New approach to III-V tandems sets 32.9% efficiency record

A collaboration between the U.S. National Renewable Energy Laboratory and Australia’s University of New South Wales has yielded a new efficiency record of 32.9% for a tandem cell device utilizing III-V materials. Key to the achievement was a new technique enabling the researchers to take advantage of “quantum wells” in the material that serve to trap charges and enable tuning of the cell bandgap to absorb more of the light spectrum.

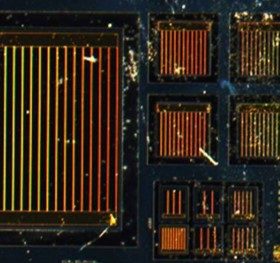

In search of cost-effective techniques for III-V cell production

Scientists in Canada have discovered a promising technique for the production of gallium-arsenide solar cells. Growing these cells directly onto a silicon substrate is a promising strategy that could cut out some of the technology’s exorbitant production costs. And by making that silicon porous, scientists may have taken a step toward producing high-performance III-V solar cells at a significantly lower cost.

Is thin-film best for offshore PV?

Superior hydrodynamic properties, more robustness in high seas and a much reduced logistics requirement support the case for thin-film over crystalline silicon, pontoon-mounted alternatives, according to an Indo-Italian research group.

Russian scientists unveil new manufacturing process for III-V solar cells

Researchers have integrated A3B5 semiconductors on a silicon substrate in a prototype solar cell and claim the technique could enable the production of III-V solar cells with conversion efficiencies of around 40%.

Solar cells from space are on the way

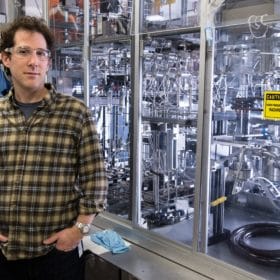

A team at the U.S. National Renewable Energy Laboratory has come up with a new process that would reduce the production cost of highly expensive – and highly efficient – gallium arsenide cells.