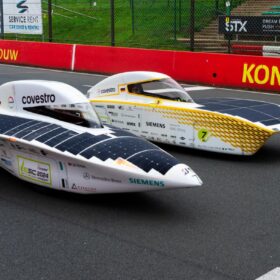

Germany’s Sonnenwagen Aachen team finishes second, third in solar race

Sonnenwagen Aachen, a student team from RWTH Aachen University in Germany, secured second and third place at the iLumen European Solar Challenge 2024, sharing the podium with Belgium’s KU Leuven team, which took first place.

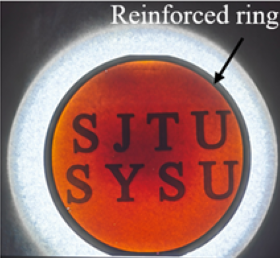

Chinese researchers develop 28-µm silicon solar cell with 20% efficiency, 0% breakage rate

A research team in China has developed a novel thin-silicon wafer reinforced ring (TSRR) to protect ultra-thin wafers and solar cells during production. This technique consists of applying the ring at the edge of thin wafers and is compatible with all silicon solar module technology.

Weekend Read: As simple as IBC

The search for ever higher conversion efficiency has driven solar researchers to focus on back-contact cell approaches, and efforts to devise more cost-effective manufacturing are bringing technologies such as interdigitated back contact (IBC) solar into the mainstream, as Mark Hutchins reports.

Webinar Q&A: The future of back contact technology

Last month, in a pv magazine Webinar held in partnership with Endurans Solar, we took a closer at Endurans’ conductive backsheet for back contact modules, and examined recent progress in back contact cell and module technologies, and their growing market potential over the next few years. Here, presenters Hugo Schoot, Business director at Endurans Solar, and Bram Verschoor, CCO at equipment supplier Eurotron, answer a more of the questions posed by the audience during the webinar.

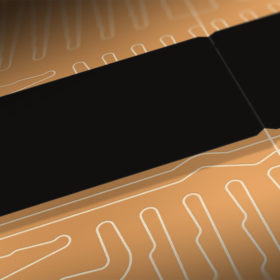

3-D multi‐ribbon interconnection tech for IBC cells

The interconnection tech, developed by scientists at the Belgian research institute Imec, is based on a three-dimensional fabric of encapsulant with incorporated horizontal and vertical solder‐coated metal ribbons. Mini solar modules built with the proposed technique have provided interesting results in tests for thermal cycling reliability, showing very limited degradation.

Futurasun doubles production capacity to 1 GW

The module manufacturer has opened its second 500 MW factory in China.

Finnish solar manufacturer gets Lithuanian factory purchase over the line

Appetite may have been lacking among private investors – at a time when global stocks are tanking amid Covid-19 and global recession fears – but the eco-friendly new Finnish government, and neighboring administrations, have stepped in to fill the breach.

New process could yield 26.6% efficient IBC cells

Researchers in Germany are trialing a host of new processes and materials to develop interdigitated back contact solar cells. A deposition technology named ‘hot-wire’ chemical vapor deposition, is said to provide excellent passivation without the need for treatments such as recrystallization or hydrogenation.

Valoe and Solitek join forces to produce IBC cells in Lithuania

The Finnish PV equipment provider and the Lithuanian PV panel maker will manufacture IBC solar cells at Solitek’s factory in Vilnius with an initial production capacity of 60 MW.

Trina hits 24.13% total-area efficiency for IBC mono cell

The new record is just 0.24% below the Chinese company’s small-area laboratory cell record and has been achieved on an industrial, large area cell.