Module reliability scorecard reveals widespread quality risk

Independent testing laboratory Kiwa-PVEL today published the 11th edition of its PV Module Reliability Scorecard, having extensively tested PV modules from 50 different manufacturers. The scorecard reveals improvements in energy yield per watt-peak and resistance to potential-induced degradation, but an increase in breakage under mechanical stress and hail simulations, and an overall higher failure rate are cause for concern to many.

EKO unveils new solar monitoring solution

The latest irradiance sensor solution from Japan-based EKO Instruments provides continuous measurements in the field. Well-suited for bifacial PV systems, it supports the measurement of global horizontal irradiance, diffuse horizontal irradiance and direct normal irradiance, even in reflective and cloudy conditions.

New performance measurement kit for outdoor testing of bifacial, perovskite solar modules

To perform a wide range of tests on new types of PV modules under realistic conditions, EKO Instruments has introduced PV Blocks, an expandable all-in-one type of system with capacity for up to 32 modules. It is targeted at research labs, module manufacturers, and testing organizations.

Fraunhofer ISE opens new outdoor solar technology test field in Germany

The new test field includes laboratory and field measurements, allowing PV modules to be evaluated faster and more accurately by combining and comparing indoor laboratory measurement results with those from the test field. The new location complements existing Fraunhofer ISE testing sites on Gran Canaria and in the Negev desert in Israel.

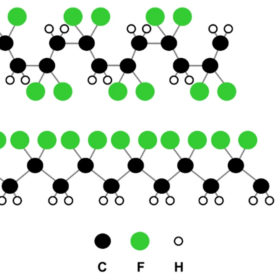

Putting polyvinylidene-fluoride backsheets to the test

US scientists tested PV modules built with backsheets and polyvinylidene-fluoride (PVDF) layers, to replicate the degradation the material has suffered in the field of accelerated testing. By exposing the modules to multiple stresses, they were able to cause degradation in the backsheet materials. Though this did not closely match what has been seen in the field, such testing can be useful in identifying potential weaknesses.

Monitoring degradation for 13 module types

In a study that began in 2016, US scientists purchased 834 PV modules, representing seven manufacturers and 13 module types, and installed them in various climate conditions to observe their performance over time. The results show that, while plenty of opportunities still exist to extend module lifetimes and reduce performance loss in the field, reductions in the manufacturing cost of PV have not come with an increase in their degradation rate.

The world’s sunniest PV testing field

French energy giant Engie recently commissioned a solar module testing facility in Chile’s Atacama Desert, a region which has the world’s highest solar radiation. Thore Müller – head of bifacial PV R&D and solar services at Engie Laborelec, talked to pv magazineabout the advantages of testing panels, inverters and cleaning systems in hot, arid environments.

US scientists claim clear-sky irradiance model provides better results for module testing

Researchers at the American Institute of Physics have used the clear-sky irradiance model developed by the National Renewable Energy Laboratory to measure the degradation rates of solar panels at a testing field in Germany over five years. The scientists say the model, when combined with real-world data, offers an efficient tool to evaluate the aging of PV technology.