Polymer-based backsheets have proven to be among the most problematic components for PV modules in the field, with examples of various types of backsheet failure leading to serious performance and safety issues in the field all too common.

Accelerated testing is an important tool in spotting the potential for failure before any specific module is used in the field. However, many backsheet materials have not shown issues in testing according to industry standards set by the International Electrotechnical Commission and other entities, but have still gone on to fail in the field.

Several years ago, US-headquartered materials giant DuPont introduced a new testing sequence, module accelerated sequential testing (MAST), where PV modules are exposed to repeated rounds of high temperature, humidity and ultraviolet light exposure, designed to better simulate conditions in the field. And the company further worked with scientists to develop this into different tests exposing modules to multiple stresses at once, which it calls combined accelerated sequential testing (C-AST). This is designed to simulate specific climate conditions such as dry deserts or humid tropical regions.

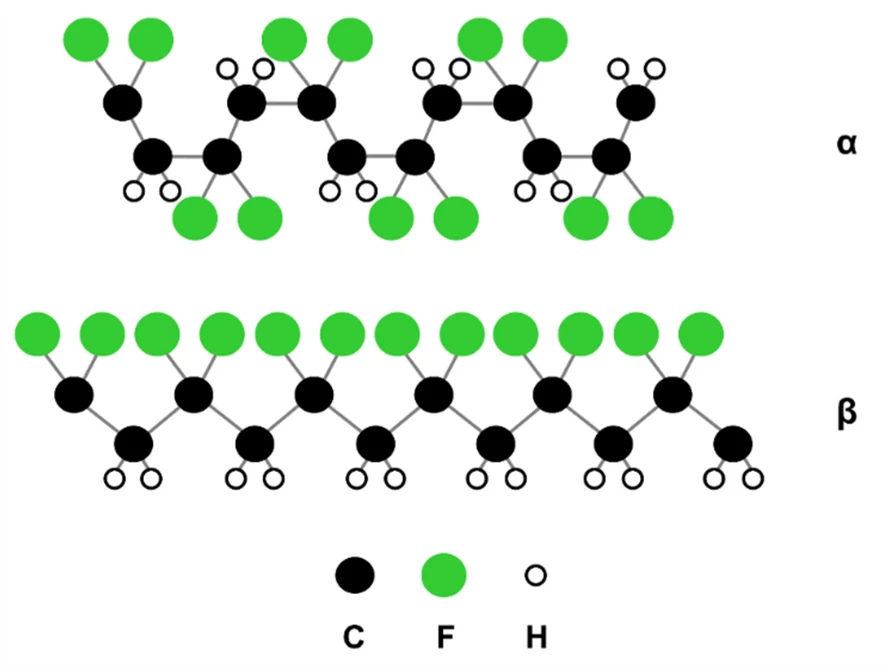

In new research, scientists at the US National Renewable Energy Laboratory (NREL) and the SLAC National Accelerator Laboratory worked with DuPont to test modules with backsheets using a layer of PVDF. They aimed to better understand the degradation mechanisms that affect the material in the field and to develop accelerated tests that mimic them accurately.

The scientists estimate that PVDF-containing backsheets represent around 50% market share currently, with the material present in various forms depending on manufacturer. A field study conducted by DuPont showed that 23% of PVDF backsheets had suffered failure after nine years in the field. DuPont manufactures Tedlar, an alternative material to PVDF also widely used in PV module backsheets.

Material change

The group subjected modules to a range of simulated harsh climate conditions, including both sequential and combined thermal cycling, damp heat, ultraviolet light, mechanical stress, rain spray and system voltage. The testing protocol is described in “A study of degradation mechanisms in PVDF-based photovoltaic backsheets,” published in Scientific Reports.

These samples were compared with two modules taken from the field at locations in Arizona and western India, both of which had been deployed for around seven years. The group noted increased crystallinity in the PVDF, which likely plays a role in the cracking that represents the most common failure mode; but says that further investigation is needed to confirm the mechanism that causes PVDF to crack.

Both types of accelerated testing produced some backsheet degradation along similar lines to those taken from the field, though neither was a close enough match to be certain of the mechanisms or cause.

“Neither of the single or sequential tests closely replicated the degradation mechanisms seen in the fielded backsheets; however, the MAST test was useful in identifying weaknesses in the material that led to failure,” the paper concludes. “Despite the fact that C-AST and MAST tests did not completely replicate the complex nature of the outdoor environment, both tests are valid for screening outdoor failure mechanisms in PVDF backsheets.”

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.