Dracula Technologies relaunches production of organic photovoltaic modules in France

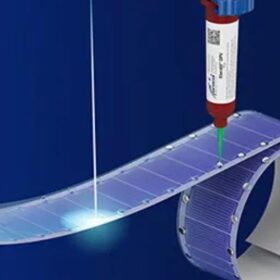

The Valence plant can produce 150 million square centimeters of active surface area of OPV modules using its inkjet printing technology, with the aim of quadrupling its capacity by 2026. Sensitive to natural and artificial light, Dracula’s modules operate indoors from any light source and are intended for use in IoT, industrial electronics and as battery replacements.

New electrically conductive adhesives for flexible perovskite, organic solar cells

Panacol, a German adhesive supplier, has launched Elecolit 3648, a one-component electrically conductive adhesive (ECA) for flexible perovskite and organic PV connections. It was conceived to adhere well to a range of materials, including several types of plastic.

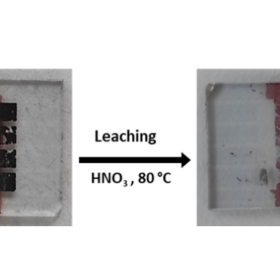

Recovering silver from PV waste via green graphene

Researchers at James Cook University have developed a process to synthesize graphene from tangerine peel oil, which they then used to recover silver from waste PV material. To demonstrate the quality of the recovered silver and the synthesized graphene, they made a dopamine sensor that reportedly outperformed reference devices.

Using digital twin, roll-to-roll platform to design high-performance organic PV devices

An international team of researchers have demonstrated how to speed up the research and development of scalable, high-performing organic solar cells by using an automated, high-throughput platform. It relies on digital twin technology and roll-to-roll (R2R) printing in a closed-loop system.

Heliatek develops lightweight organic PV module for low load-bearing roofs, facades

German organic PV manufacturer Heliatek has announced a new series of lightweight modules. The Heliasol 436-2000-CFE-45-600V panels are IEC 61215 and IEC 61730 certified and have a 20-year lifetime warranty.

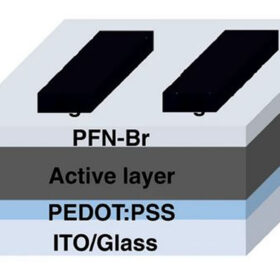

Organic solar cell based on trichlorobenzene achieves 19.31% efficiency

An international research team developed an organic solar cell based on a novel non-monotonic intermediated state manipulation strategy. The device reportedly showed non-radiative recombination losses while exhibiting remarkable power conversion efficiency.

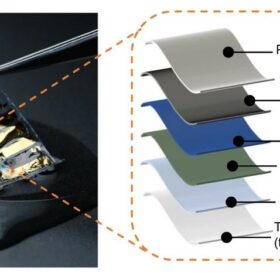

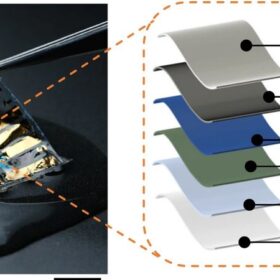

Japanese researchers build 14.3%-efficient bendable, waterproof organic solar cell

Researchers from Japan’s Riken Center for Emergent Matter Science have fabricated an organic solar cell that has achieved waterproofness without reducing flexibility. At 3 micrometers thick, it is thought to be the first cell of its kind to survive a washing machine cycle and retain efficiency after multiple cycles.

Japanese researchers develop waterproof, flexible organic solar cell with 14.3% efficiency

The organic cell retained 89% of its initial performance after being immersed in water for four hours and survived a washing machine cycle. The researchers plan to develop the technology further, with an end goal of using it for wearable devices.

Large area organic PV module achieves world record efficiency of 14.5%

The module has a size of 143 mm x 143 mm and an active area of 204.11 cm². The result was certified by the Fraunhofer Institute for Solar Energy Systems (Fraunhofer ISE).

Dyenamo expands materials offer for perovskite-silicon tandem solar cells

In response to its customers’ needs, Sweden’s Dyenamo has added several new perovskite product lines and increased production of materials for the full range of perovskite solar cell designs.