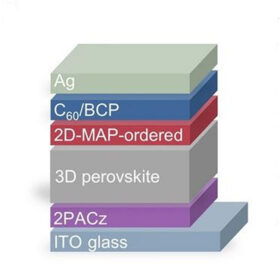

Perovskite solar cell based on 3D/2D heterostructures achieves 26.05% efficiency

Developed by an international team including Saudi Arabia’s KAUST and the Chinese Academy of Science, the solar cell is claimed to be one of the most efficient perovskite PV devices based on 3D/2D heterostructures built to date.

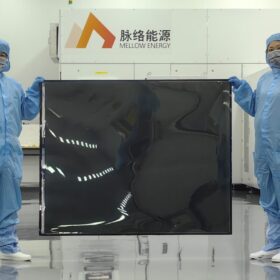

Chinese startup unveils flexible perovskite photovoltaic modules with 15.6% efficiency

Mellow Energy claims its ML-Flex panel is currently the world’s largest flexible perovskite solar module. Available in five versions with power output ranging from 260 W to 300 W, the module measures 1,200 mm x 1,600 mm and weighs only 2.04 kg.

Japanese railway operator testing perovskite solar on noise barriers

Central Japan Railway Co. and Sekisui Chemical have revealed plans to deploy flexible perovskite-based PV systems along the Tokaido Shinkansen train line in Japan. They are using thin, lightweight, flexible film-type perovskite solar cells.

Bifacial perovskite solar can achieve bifaciality of 90% when tilted at 20 degrees

New research from India has shown that bifacial perovskite solar cells can achieve a 2% higher power conversion efficiency with a tilt angle of 20 degrees. The scientists also developed a bifacial perovskite solar cell for applications in both tandem or single-junction PV devices.

Chinese developer switches on world’s largest perovskite-based PV plant

MicroQuanta, a Chinese perovskite solar specialist, has commissioned a 8.2 MW PV facility based on its 90 W perovskite panels in eastern China.

Danish print finishing equipment provider offers turnkey pilot lines for perovskite, organic solar cells

Denmark-based Grafisk Maskinfabrik (GM) is now selling roll-to-roll turnkey pilot production lines featuring slot-die coating, available through its GM Functionals unit.

European team targets 20%-efficient perovskite modules using industrial processes

The LUMINOSITY project consortium aims to develop 20%-efficient metal halide perovskite prototype modules measuring over 900 cm², designed for a 20-year lifespan and compatibility with roll-to-roll (R2R) processing.

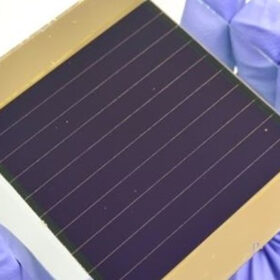

Perovskite solar cell built with slot die coating achieves 19.17% efficiency

A team from Jeonbuk National University in South Korea used slot die coating (SDC) to produce uniform high-quality perovskite films, which they used in a perovskite solar cell that achieved 19.17% efficiency and lab cell-sized modules that achieved 17.42% efficiency.

New cleaning tool for perovskite, organic PV roll-to-roll production equipment

A German research team has developed a precise cleaning process for electrode deburring in perovskite and organic solar PV roll-to-roll production lines. It is based on commercially available equipment from Germany-based Acp Systems.

Perovskite solar module achieves 21.44% efficiency via new passivation tech

Researchers have developed a novel passivation process for formamidinium lead iodide perovskite films, which reportedly resulted in solar cells with 23.69% power conversion efficiency, and modules with 21.44% certified efficiency. After 1000 hours, the hetero-polytypic passivated devices maintained 92% of their initial efficiency, outperforming untreated devices.