Doping delivers improved performance for perovskite solar cells

Some of the world’s largest solar PV module manufacturers are warning about looming panel shortages, but Australian researchers have declared that the industry is now drawing closer to a new generation of cheap, sustainable and efficient solar cells.

Building perovskite solar cells with waste toner carbon

Scientists in China have fabricated 11.78%-efficient fully printable perovskite solar cells by using an electrode made of waste toner carbon from printer cartridges. The cell achieved an open-circuit voltage of 0.88 V, a short-circuit current density of 24.64 mA cm, and a fill factor of 54.56%.

Russian scientists achieve 21.1% efficiency in perovskite solar cell via Mie-resonant silicon nanoparticles

A Russian-Italian research group has developed resonant silicon nanoparticles that are claimed to improve the performance of perovskite solar cells. These particles serve as nanoantennae – they catch light and it resonates inside them, which amplifies the cell’s light absorption.

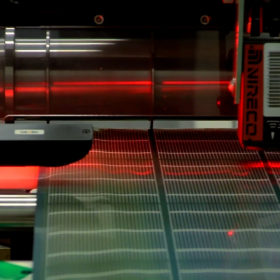

Co-evaporated perovskite solar cell with 20.6% efficiency

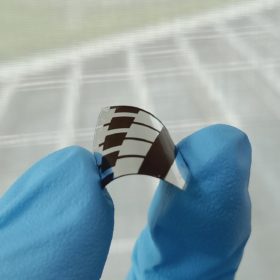

Researchers in Singapore have built what they claim is the industry’s most efficient, large-area co-evaporated solar cell. According to their findings, the device has exhibited remarkable thermal stability and could reach commercial maturity within the next few years.

Co-evaporated perovskite solar cell with 19.5% efficiency

German scientists have built a perovskite solar cell with spiro-TTB as a hole transport material, via the thermal co-evaporation method. The solar cell has an open-circuit voltage of 1.08 V, a fill factor of 83.0%, and a short-circuit current of 21.6 mA cm.

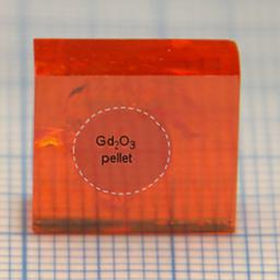

Perovskites can also detect nuclear radiation

Scientists in Switzerland found that perovskites can be used to detect thermal neutrons emitted by radioactive devices. Taking advantage of several properties that also make the materials attractive for solar cell applications, the group was able to fabricate a novel device that could have various practical applications, including in energy generation.

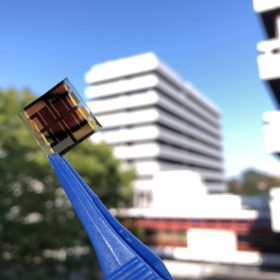

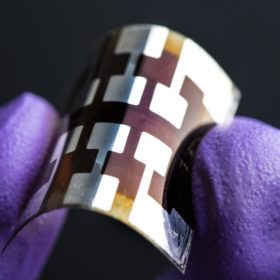

Single crystal perovskite solar cell with 17.8% efficiency

The solar cell was manufactured with crystals that were grown directly onto indium tin oxide (ITO) substrates covered with hole transport layer (HTL). These substrates have a controlled thickness of tens of micrometers and area of tens of mm2. The device showed an efficiency of 17.8%, a short-circuit current of 21.0 mA cm−2, an open-circuit voltage to 1.08 V, and a fill factor to 78.6%.

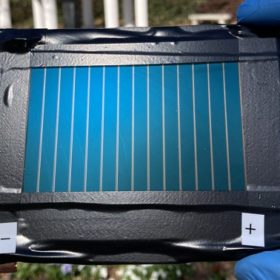

Photovoltaic sunshade based on perovskite solar cells

The phovoltaic sunshade was deployed on the facade of a factory owned by Polish aluminum system provider Aliplast. The movement of the PV blinds is regulated by a controlling system linked to a weather station installed on the roof.

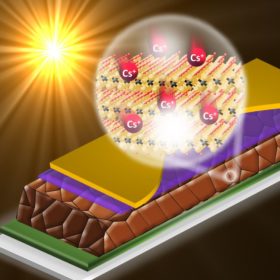

Mini perovskite solar module with 19.2% efficiency via new additive

The efficiency of the module was certified by the U.S.’ National Renewable Energy Laboratory. It was built with perovskite solar cells with a stabilized efficiency of 23.6%, an open-circuit voltage of 1.17 V, a short-circuit current density of 24.1 mA per cm−2, and a fill factor of 0.842.

Perovskite-silicon tandems could rapidly scale solar

Halide perovskites combined with conventional silicon could help solar break the 26% efficiency barrier – disrupting the technology without disrupting business systems.