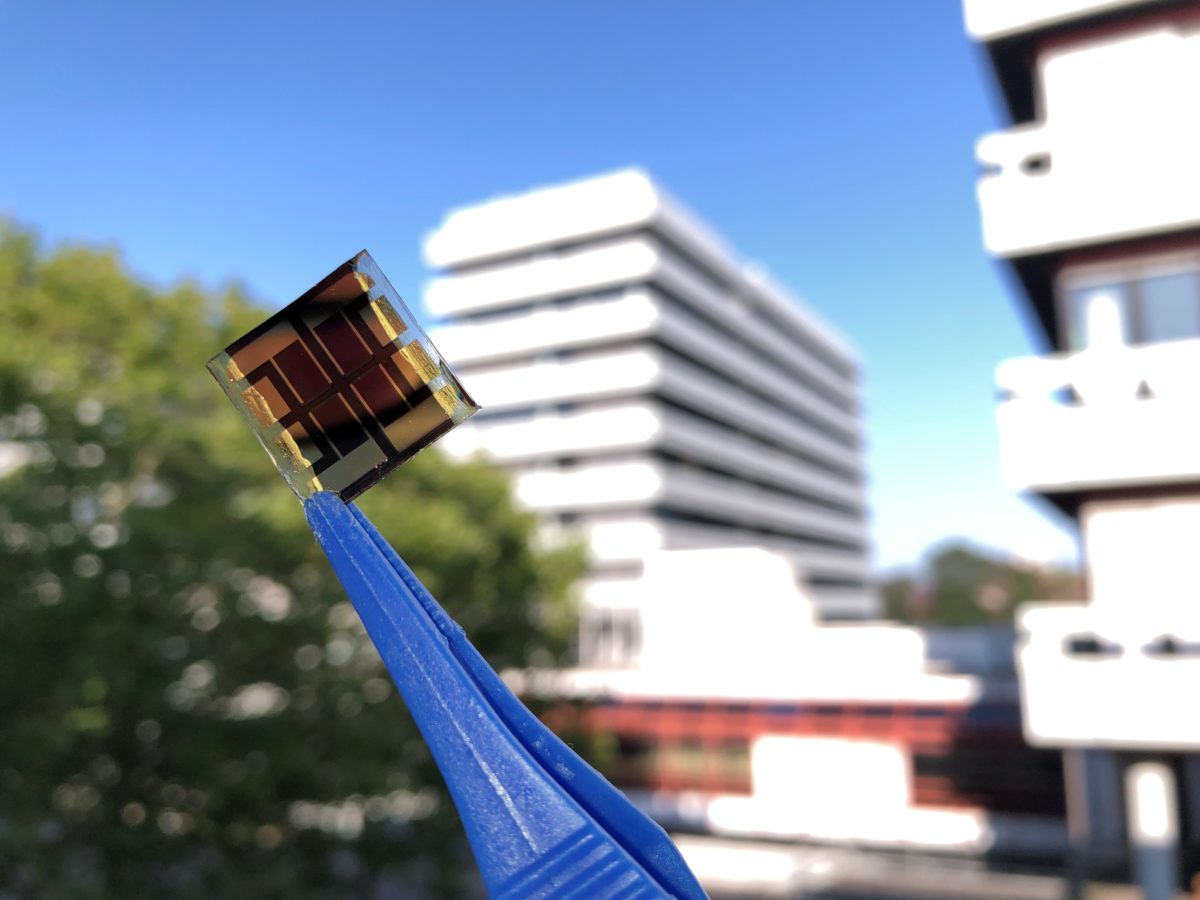

Scientists from the Karlsruhe Institute of Technology (KIT) and the Technical University of Darmstadt in Germany have developed a 19.5%-efficient perovskite solar cell via the thermal co-evaporation method, which involves a thin layer coating. The source material evaporates in a high vacuum chamber.

Compared to solution-based techniques, which the research group described as highly sensitive to solvent choice, process conditions, and even process atmosphere, the co-evaporation process is said to require fewer process parameters. The scientists said that the choice of substrate material and the crystallographic properties of the co-evaporated perovskite thin film are also decisive for the chemical reaction between lead(II) iodide (PbI2) and methylammonium iodide (MAI) in forming the cell perovskite absorber.

Controlling and monitoring the growth and composition of these two elements during co-evaporation is the main challenge of this manufacturing step.

“Columnar grain growth is identified as highly substrate dependent and as the key characteristic for high-quality co-evaporated perovskite absorbers,” the academics explained. “Perovskite thin-film morphologies without horizontal grain boundaries are commonly preferred.”

They fabricated the device with an undoped vacuum-processable hole transport material (HTM) called 2,2“,7,7”-tetra(N,N-di-p-tolyl)amino-9,9-spirobifluorene (spiro-TTB).

“The co-evaporation of the perovskite absorber in this layer stack sequence results in the desired homogenous columnar grain growth of the perovskite thin film,” the researchers said, noting that this was the decisive factor in achieving a stabilized efficiency of 19%.

They claimed that the simplified device architecture on the hole transport layer (HTL) side and the use of a bathocuproine (BCP) buffer layer between the fullerene layer and the rear electrode, which facilitated better charge carrier transport and extraction, which in turn resulted in high values for fill factor and open-circuit voltage.

Popular content

“These devices are among the best reported all-evaporated perovskite solar cells without a solvent-based step in any of the utilized functional layers,” they said.

The best solar cell build under this configuration achieved a power conversion efficiency of 19.5%, an open-circuit voltage of 1.08 V, a fill factor of 83.0%, and a short-circuit current of 21.6 mA cm.

Researcher Tobias Abzieher said that the commercialization of perovskite-based PV is on its way. He said he is confident that the vapor-based route will be of significant importance for this step.

“While the general process equipment itself is already available from other thin-film technologies and should at least partially be able to be transferable to the deposition of perovskite-based semiconductors, the exact process engineering is still something that requires some research effort, which is however under heavy research these days,” he told pv magazine.

The scientists described the solar cell in “From Groundwork to Efficient Solar Cells: On the Importance of the Substrate Material in Co-Evaporated Perovskite Solar Cells,” which was recently published in Advanced Functional Materials.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

2 comments

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.