DuPont Teijin Films: Recycled PV backsheets are technically viable

UP Initiative sponsor, DuPont Teijin Films is investigating closed loop recycling processes, specifically looking at how its backsheets can be recovered and used as a raw material for new production. Since 2020, it has been working on industrial trials with customers to offer rPET backsheets across its entire product range, and proof of principal trials to demonstrate the commercial feasibility of a true closed loop recycling process. pv magazine caught up with Steven Davies, EMEA market manager to discover what progress has been made in the last year.

Recycling options for PV panels, batteries could drive circular economy, says NREL

Renewable hardware that lasts longer and uses fewer materials could bolster recycling efforts and help to build an effective circular economy for solar and battery technologies, says the US National Renewable Energy Laboratory (NREL).

Recycling process promises ‘better than new’ silicon wafers

Scientists in China have developed a new recycling process for PV modules that can recover intact silicon cells from end-of-life products, and process them back into wafers. As part of the recycling process, the wafers are purified and surface-treated, making them suitable for integration into new, high-efficiency cells and modules.

Australian solar module manufacturer commits to recycling strategy

Reclaim PV has added another partner to its national solar panel recycling and recovery program with South Australian-based manufacturer Tindo Solar committing to a program that will see close to 100% of the solar PV panels that it handles recycled and re-used in the industry.

Reuse or replace? IEA PVPS analysis considers all options for underperfoming PV modules

In a new report, experts from the International Energy Agency Photovoltaic Power System Programme (IEA-PVPS) have assessed the economical and environmental benefits of repairing and reusing or replacing solar modules that are not complying with a 30-year expected lifetime. They found that reusing offers the best environmental impact in all cases, while the profitability of this option is currently guaranteed only by rooftop PV under certain conditions. As for large-scale solar, module replacement remains the most competitive option.

Module durability, and design for recycling

A new report published by the International Energy Agency offers a series of guidelines for the design of recyclable PV modules. The report aims to help manufacturers find the balance between durability and recyclability, to better address concerns about the 78 million tons of end-of-life PV modules expected by 2050.

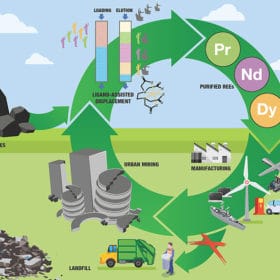

Recycling rare-earth elements from dead lithium batteries

American Resources Corporation is developing a process to separate pure rare earth metals from lithium-ion batteries used in electric vehicles or power plants based on renewable energy. The technique is described as a two-zone ligand-assisted displacement chromatography (LAD) that is able to produce metals with high yields and purity of over 99%.

Australia’s recycling opportunity emerges as batteries boom

Australia’s national science agency has identified a potential AUD 3.1 billion ($2.4 billion) industry, as the increasing penetration of renewable energy continues to drive growth in the battery energy storage sector.

New delamination technique for PV module recycling

French research institute CEA-Liten has created a technique that consists of using a diamond wire to cut through the photovoltaic cells, separating the module’s glass front face from the polymer-based backsheet. The process is claimed to be low-polluting and low-energy.

Australia’s first large-scale PV recycling operation amps up ‘waste’ collection

Reclaim PV is now one step closer to ensuring that solar generation lives up to the promise of providing clean energy throughout its life cycle, and that repurposing its component materials becomes viable.