Copper metallization process reaches pilot production in Germany

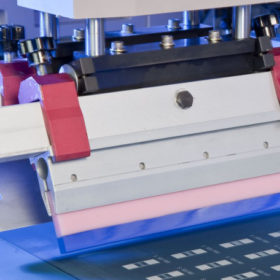

Scientists led by staff from Germany’s Fraunhofer ISE have demonstrated a new laser printing process in pilot production, which could replace silver paste and screen printing in solar cell manufacturing. The system is said to offer much more flexibility in the layout of contact fingers on the cell surface and a wider choice of metallization materials.

Slimming down on silver

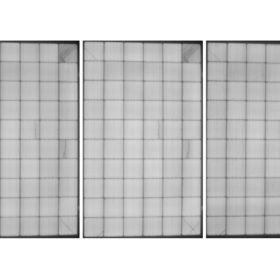

Using an innovative high-speed video setup, scientists in Germany were able to observe the screen-printing process used in solar cell metallization, on a time scale of less than 50 milliseconds. Insights into the paste’s behavior and the mechanisms at work during screen printing will improve the process and the formulation of the silver paste it relies on.

Silver price rally won’t affect PV industry

Silver prices reached their highest levels this week since 2016. But Michael DiRienzo, executive director of The Silver Institute, says prices are still not high enough to complicate silver supplies for the PV industry.

New metallization paste range from Heraeus

The SOL 7 series comprises five products for Perc, Topcon and heterojunction devices.

Silver demand for PV manufacturing may have peaked in 2019

A Silver Institute study says demand for the precious metal for solar manufacturing accounted for 11% of global consumption last year but reduced solar generation capacity up to 2023 will eat into that figure and ‘thrifting’ technological advances will kick in after that point.

Silver prices expected to drop 3% in 2020

According to the 2020 World Silver Survey 2020 by the U.S.-based Silver Institute, the metal’s price will decline by only 3% this year, despite the impact that the Covid-19 crisis will also have on demand. In the global PV industry, silver demand is forecast to drop 3% from 98.7 million ounces in 2019 to 96.1 million ounces this year.

The raw materials needed for the European Green Deal

A team tasked by the European Commission with estimating the raw material requirements of the European energy transition found if global PV roll-out is high, and the component requirements of certain solar technologies don’t improve by a greater margin, some elements could end up in short supply.

New metallization tech to reduce microcracks in solar cells

A U.S. research group has developed a metal-carbon-nanotube composite – MetZilla – which can be embedded in commercial, screen-printable silver pastes and is said to reduce the formation of hotspots in solar modules and to prolong panel lifespan. The composite metal contacts are also ‘self-healing’ as they are able to regain electrical continuity after cycles of complete electrical failure caused by extreme strain.

New metallization process cuts silver demand for modules by 30%

Fraunhofer ISE has worked with German technology companies to improve the metallization process in silicon solar cells. The result could drive down module costs quite a bit.

pv magazine Quality Roundtable, REI: Innovation, investment and improving PV installs

pv magazine’s Quality Roundtable at the 2018 Renewable Energy India (REI) Expo, took place in front of a packed audience. It discussed current problem areas in the India solar industry; how solar developers and solution providers can improve the quality of PV installations; and innovative financial instruments to reduce the cost of debt and scale up infrastructure investment.