Taiwanese consortium develops easily recyclable solar module

The Industrial Technology Research Institute (ITRI) and United Renewable Energy (URE) have developed a solar panel that can be easily dismantled to simplify the recycling process. They claim that 96% of the materials in the panel can be recovered, including all of the solar cells and front glass.

New study looks at Sundrive’s 25.54% silver-free heterojunction solar cell

A new scientific paper takes a closer look at the record-breaking efficiency that Australia’s Sundrive announced for a silver-free heterojunction cell in September 2021, as certified by Germany’s Institute for Solar Energy Research.

IEA-PVPS expects polysilicon prices to stabilize by end of 2023

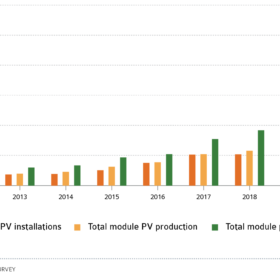

The International Energy Agency Photovoltaic Power Systems Programme (IEA-PVPS) recently published a report on trends in PV applications for the 2021-22 period. Prices for polysilicon, wafers, cells and modules rose, while production capacity expanded in China and beyond.

Novel tech to recycle silver, aluminum from end-of-life solar panels

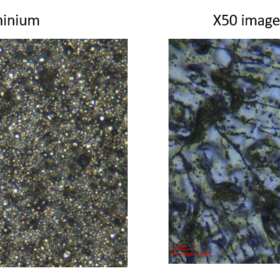

Researchers at the University of Leicester have developed a new method of extracting silver and aluminum from end-of-life PV cells using iron chloride and aluminum chloride dissolved in brines. According to them, the cheap solvents retrieve up to 95% of the metals within 10 minutes, achieving a 98% purity of silver chloride.

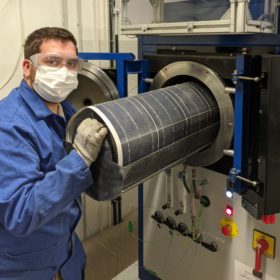

Heterojunction solar cells with lower silver consumption via rotary screen printing

Scientists from the Fraunhofer ISE built a bifacial heterojunction solar cell with a power conversion efficiency of 21.7% via rotary screen printing. They used a machine that is able to achieve a cycle time of just 0.6 seconds per solar cell and enables a strong reduction in silver use.

Silver prices rose 22% in 2021, but slight decrease expected this year

The US-based Silver Institute’s “World Silver Survey 2022” report shows that the price of the metal will fall slightly this year, despite the global economic impact of the war in Ukraine.

Chinese PV Industry Brief: Jolywood, Jinko expand polysilicon capacity

In other news, Canadian Solar revealed it shipped 14.5 GW of solar modules in 2021 and China Power said it installed 1.22 GW more solar generation capacity last year.

Demonstrator machine for high-throughput solar cell metallization

Developed by Germany’s Fraunhofer Institute for Solar Energy Systems ISE and ASYS Automatisierungssysteme GmbH, the new machine is claimed to increase the print process throughput by a factor of 1.5.

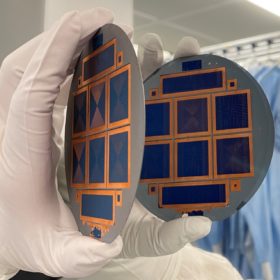

Copper-plated heterojunction solar cell with 22.1% efficiency, 0.99 bifaciality factor

Built by a Dutch-Chinese research team, the cell is relying on a new type of hybrid-shaped Cu finger consisting of a rectangular bottom part and a round top part, which was integrated into the cell through a 2-step electrochemical deposition process. The Cu-plated device outperformed both optically and electrically a reference cell fabricated via screen printing.

New PV module recycling tech from France

French start-up Rosi Solar has developed an industrial solution claimed to be capable of recovering high purity silicon, silver and copper contained in end-of-life PV modules. The company’s technology is based on a pyrolysis process that makes it possible to isolate the different metals from the cells.