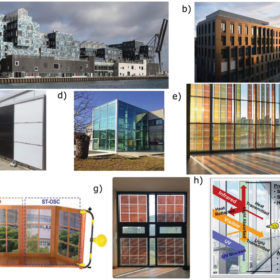

Tunable solar cells with customized design capabilities

German scientists have reviewed all solar cell technologies with tuning capabilities and have identified all of their possible applications.

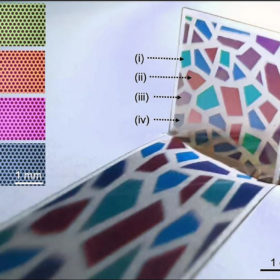

Perovskite microcells for solar windows

Developed by Korean scientists through a novel lift-off-based patterning approach based on swelling-induced crack propagation, the perovskite PV device achieved an open-circuit voltage of 1.16 V, a short-circuit current density of 22.5 mA/cm2, and a fill factor of 77%. With the microcells, the researchers also built a first prototype of a solar window which they claim has vivid colors and high color purity.

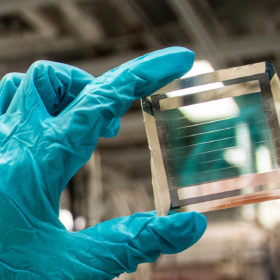

Major advances for US, Australian solar window specialists

Australian solar window supplier ClearVue says its products can reduce carbon emissions in buildings by as much as 90%, while California-based BIPV window coating producer Ubiquitous Energy has raised $70 million to scale up its own tech.

Semi-transparent antimony trisulfide PV cell for solar window applications

The 5.5%-efficient cell was fabricated through a low-temperature, two-step manufacturing process that is compatible with existing window glass manufacturing technology. Cells made with 70nm antimony trisulfide films achieved the best fill factor of around 57%, while the highest power conversion efficiencies were achieved with films ranging from 70 to 100nm.

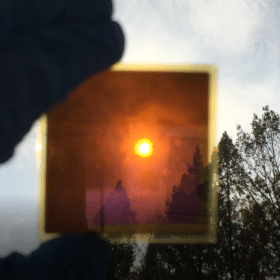

Quantum dot solar window with 3.6% efficiency

U.S. manufacturer UbiQD has developed a solar window with laminated glass and luminescent solar concentrators, based on copper indium sulfide and zinc sulfide quantum dots. It is now testing pilot installations in Nevada.

Semi-transparent organic solar cell for window applications

Developed by U.S. scientists, the 10%-efficient device is intended for applications in solar windows and promises efficiencies close to 15%. According to its creators, the cell retained 80% of its efficiency after 1,900 hours at 55 degrees Celsius.

Ever heard of photovoltachromics, the new tech for solar windows?

Researchers in China have developed a smart solar window tech based on a photovoltachromic device that is able to achieve a high pristine transmittance and to be self-adaptable to control indoor brightness and temperature. The device was assembled via a full solution process in an architecture incorporating glass, a fluorine-doped tin oxide (FTO) layer, a perovskite-based PV cell, an electrochromic gel, another FTO layer, and glass.

Nanoparticles enable completely clear, industry-sized solar windows

Australian company ClearVue Technologies says it has a fully transparent, scalable, industry-ready solar window in production. It claims that it’s now just 18 months away from cracking 5% efficiency, thanks to a research partnership.

Solar window based on luminescent solar concentrators

U.S. scientists have put luminescent solar concentrators in a windowpane to absorb certain light wavelengths and transmit them to solar cells. The concentrators are made of a conjugated polymer sandwiched between window layers.

Semitransparent bifacial CIGS cell with 10.5% efficiency

The solar cell was developed by Korean scientists for power-generating window applications. They built the device with transparent conducting oxide (TCO) rear contacts and a textured polydimethylsiloxane (PDMS) layer with light-scattering and antireflection properties.