As perovskite solar cells move rapidly toward commercial production, questions about their long-term stability and heat and moisture sensitivity linger.

While all-organic perovskites have trailed organic-inorganic alternatives, the technology has shown plenty of potential – particularly in terms of overcoming stability issues – and remains an active area of interest for researchers. A group at Rice University has discovered, by replacing some of the lead in an inorganic perovskite with indium they were able to increase the material’s stability whilst maintaining efficiency.

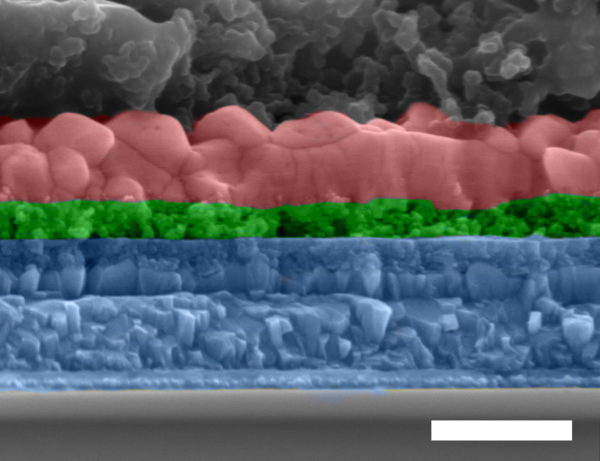

The group’s experiments, described in a paper published in Advanced Materials, took an inorganic perovskite – cesium lead iodide – and found that through defect engineering involving the strategic addition of indium and bromine to the material, they were able to greatly suppress the concentration of imperfections.

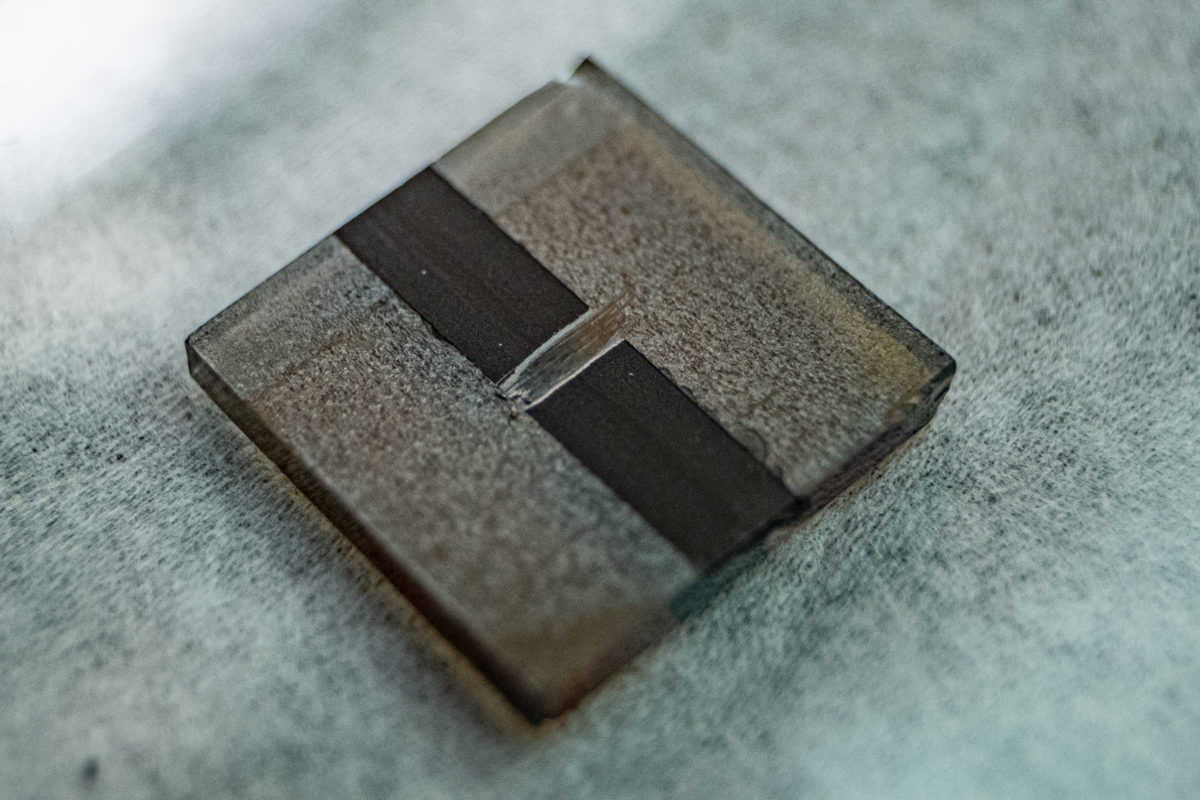

The small cells created by the group demonstrated maximum efficiency of 12.04% and an open circuit voltage of 1.2 V. More importantly, according to the Rice team, the cells could be prepared in ambient conditions and encapsulated versions remained stable for more than two months in air, noting that previously the cells had only lasted for a few days.

Popular content

Image courtesy of the Lou Group

“Engineers are developing capping layers and things to protect those precious, sensitive materials from the environment,” said Jun Lou, a materials scientist at Rice University. “But it’s hard to make a difference with the intrinsically unstable materials themselves. That’s why we set out to do something different.”

The group estimates, with further optimizations the same material could achieve efficiencies of around 20%. “If we can get there, this can be a commercial product,” said Jia Liang, the paper’s lead author. “It has advantages over silicon-based solar cells because synthesis is very cheap – it’s solution-based and easy to scale up. Basically, you just spread it on a substrate, let it dry out and you have your solar cell.”

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.