Scientists led by Warwick University in the UK investigated the effect of ambient atmosphere exposure during production or storage on nickel-rich cathodes, finding that keeping the materials free of moisture is key to getting the most out of the battery they will ultimately be used in.

Largely due to concerns and instability in the supply chain for cobalt, battery manufacturers are increasingly turning to either cobalt free or ‘nickel rich’ designs, typically utilizing 80% nickel, 10% manganese and 10% cobalt (NMC 811). And since moisture is a problem for many cathode structures, researchers at Warwick University set out to investigate the mechanisms it could trigger within the NMC-811 material and to define the ideal conditions for manufacture and storage of the cathodes before being built into batteries.

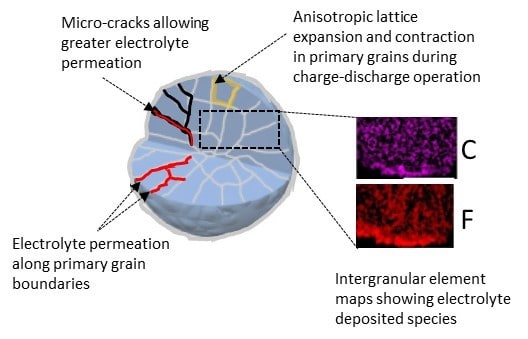

A group at Warwick exposed cathodes to varying temperatures and humidity and then analyzing their battery performance using a range of testing and imaging techniques. The research is described in the paper The effects of ambient storage conditions on the structural and electrochemical properties of NMC-811 cathodes for lithium-ion batteries, published in Electrochimica Acta.

Compared to a control sample, both cathodes left ‘as exposed’ and others that were oven-dried after exposure to moisture showed reduced initial capacity and inferior cycling performance. The group puts this down to the formation of oxides and carbonates in the materials following exposure to the atmosphere, which then irreversibly reduces both ionic and electrical conductivity.

“Whilst moisture is well known to be problematic here, we set about to determine the optimal storage conditions that are required to mitigate unwanted, premature degradation in battery performance,” explained Melanie Loveridge of Warwick University. “Such measures are critical to improve processing capability, and ultimately maintain performance levels. This is also of relevance to other Ni-rich systems e.g. NCA materials.”

While battery manufacturers are well aware of the need to shield cathode materials from moisture and atmospheric conditions, understanding the mechanisms that cause the problems will be valuable in developing moisture stable materials, or defining the ideal conditions for storage and manufacture of NMC-811 cathodes.

Cathodes in this research were left exposed for a period of 28 days, which the researchers say is aligned with practical periods of storage that would be seen in manufacturing facility. However, the next stage of their research will focus on the effects of short term moisture exposure, bringing more potential for optimization of both processes and materials in NMC battery manufacturing.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.